The fastest and most secure way to protect the watches and jewelry you love.

We've minimized the paperwork and maximized protection, so you can stop worrying about your watches and jewelry and focus on enjoying them.

In most cases, you'll get a personalized quote in seconds and your policy kicks in immediately.

Wherever you are on planet Earth, your watches and jewelry are protected. Rest easy and travel safely.

If you suffer a covered loss, there's no deductible and no gimmicks. Ever.

Each of your watches and jewelry is covered up to 150% of the insured value (up to the total value of the policy).

Our quotes are based on historical sales and real-time market data allowing us to give fair prices without all the hassle.

Popular Searches

Introducing MB&F Brings Back The LM Sequential Chronograph, Now With Flyback

A Week On The Wrist The Ressence Type 1 Squared In Night Blue

Introducing The Gérald Genta Gentissima Oursin

Inside The Manufacture A Tour Of Tudor's New Manufacture In Le Locle

A look into the inner halls of tudor's cutting-edge new facility and the home that it shares with kenissi..

Editors’ Picks

How To Wear It The Cartier Tank Cintrée

In-Depth Examining Value And Price Over Time With The ‘No Date’ Rolex Submariner

Watches In The Wild The Road Through America, Episode 1: A Model Of Mass Production

A few weeks ago, just before the buzz and bustle of Watches & Wonders, I found myself climbing the confined staircase of a double-decker tour bus. I had come to Geneva a couple of days early thanks to an invite from Tudor offering a tour of the brand's newly-opened facility in Le Locle, Switzerland. Not one to turn down such an invite – not to mention a recent delivery of a Pelagos 39 that had been assembled in the new facility – the day promised a rare glimpse inside the often secretive but evolving world of Tudor. Checking the time on that very same watch, I watch from the upper deck as other members of the watch press filed out of the hotel and found a seat on the bus.

The drive from Geneva to the new Tudor facility should take about two hours as we roll out of the city on the lake and head into Le Locle, one of the main centers of watchmaking for the entire Swiss industry. Interestingly, despite having been around for some 97 years, this is Tudor's first exclusive production site. Construction began in 2018 and the building was completed in 2021, offering Tudor a specialized home in the ideal area to connect with suppliers, industrial capability, and – crucially – trained watchmakers.

The total building is over 114,000 sqft and offers more than 60,000 sqft of workspace for the assembly, testing, and quality control of Tudor's watches, which number more than 700 references and are sold in 80 countries around the world. From an engineering standpoint, the building represents a fully modern and entirely considered solution, complete with a specialized HVAC system to provide ideal control over temperature and humidity, self-tinting electrochromic windows, and some 442 solar panels to help power the whole operation.

Divided into two logical parts, one element of the new facility is dedicated to Tudor's operations, including the assembly floor, the testing floor, and quality control (including component checks, bracelet fitting, and engraving). The other side of the facility is dedicated to Kenissi, Tudor's movement manufacturing outfit.

We start at the movement side of the new facility with Kenissi.

Watchmakers at work assembling Tudor movements.

For those that have never found it all that clear, Kenissi was founded and is owned by Tudor. The result of Tudor's work in creating their own movement back in 2015, Kenissi was launched in 2016 as a subsidiary of Tudor that manufactures and assembles movement not only for Tudor (duh), but also Chanel (who owns a piece of the Kenissi business), Breitling, TAG Heuer, Norqain, and others. That being said, Kenissi is Tudor.

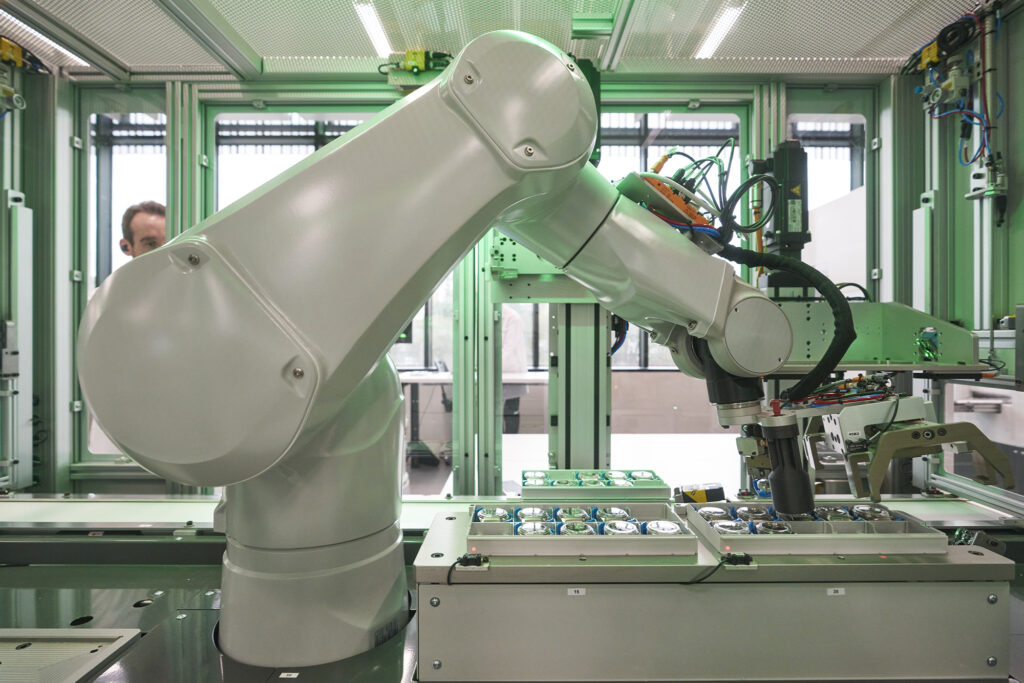

A watchmaker sits at their desk, which includes a tiny built-in production that manages movements throughout the hand assembly process. A movement is delivered to the watchmaker, they do their work, and it then rejoins the cue flowing through the desks from a centralized storage hub that is supported by a robotic arm.

Kenissi manufactures movements that fall into one of three families and the company currently produces about 80% of the components for a given movement (with the rest being supplied via close partners). The new Tudor facility offers a pair of identical assembly lines that feed components, and, after hand-assembly, final movements to a series of stops along a largely automated line. Interestingly, where Kenissi is vertically integrated, Tudor's non-movement production is much more horizontally integrated as the various components are produced either via brand partners or through ancillary companies that Tudor owns in Switzerland.

Movements are delivered via a specialized system of tunnels that connect each desk with each stage of the movement assembly.

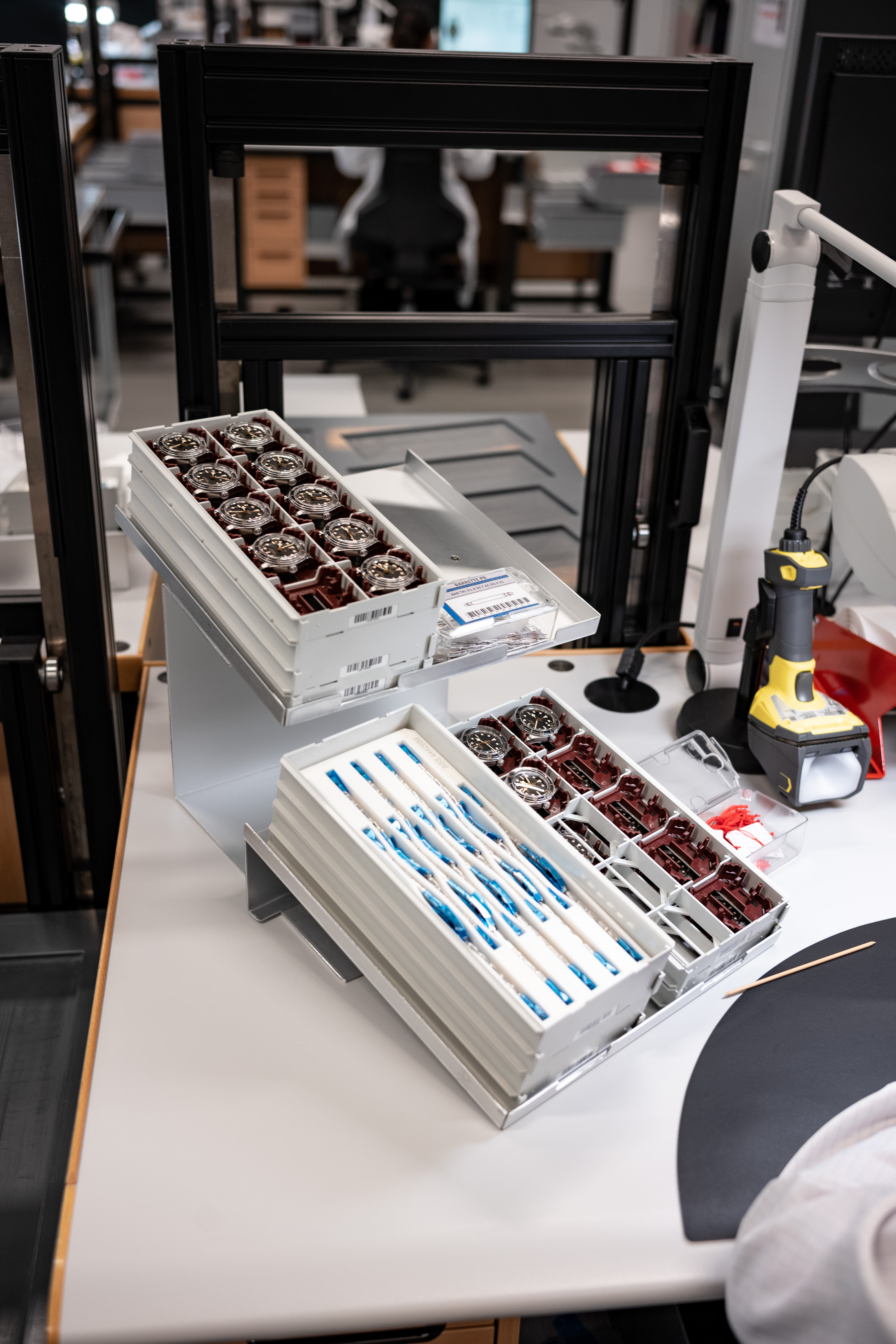

Tiny movements in plastic holders flow through translucent tunnels, in and out of the hands of watchmakers, all controlled by computers and specialized processes. When the movement is ready, it heads to the other side of the building, where it is installed into a Tudor watch on the assembly floor.

The assembly floor feels a lot like other watch manufacturers I've visited. Groups of nested watchmaking workspaces allow the various components of the watch to come together via the hands of a skilled watchmaker. Each cell of desks is capable of assembling and checking any reference and the entire process operates on a "no stock" philosophy, so production is based on actual demand from clients and retailers. Brand new air circulates through 3.5 times per hour and the flow of the air in the space has been specifically designed to keep dust to an absolute minimum.

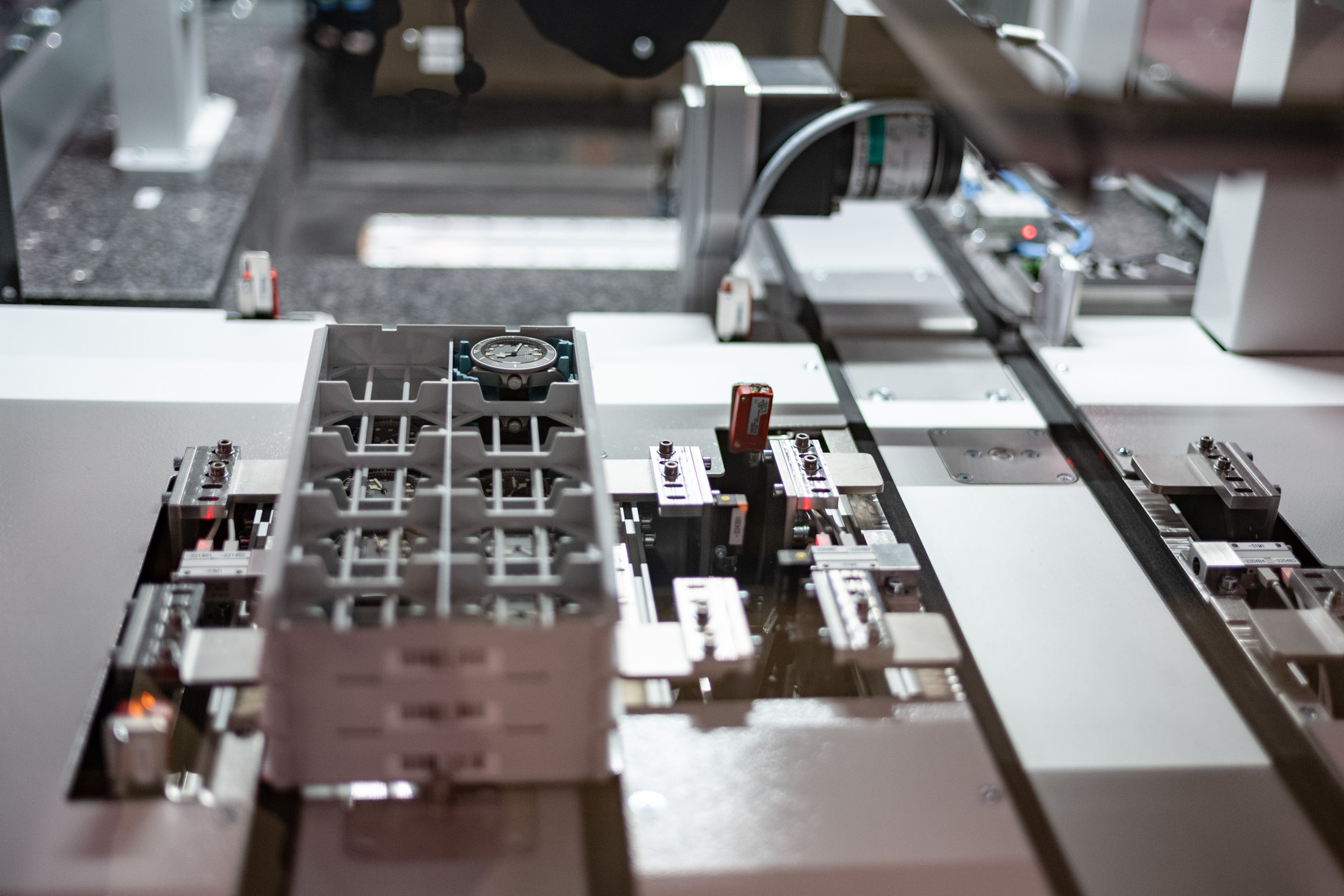

The next stop is the testing floor, in which partially assembled watches (no strap or bracelet) are subjected to a battery of tests that pertain to either METAS or TPC (that's Tudor Performance Control) stipulations. This area is fully autonomous, running 24 hours a day with the support of some very cool robots. The watches are pressure tested, checked for precision, subjected to extreme magnetism (especially for the METAS certification), and are even tested for the proper functioning of the power reserve. Can you spot some of the interesting models we saw mid-testing?

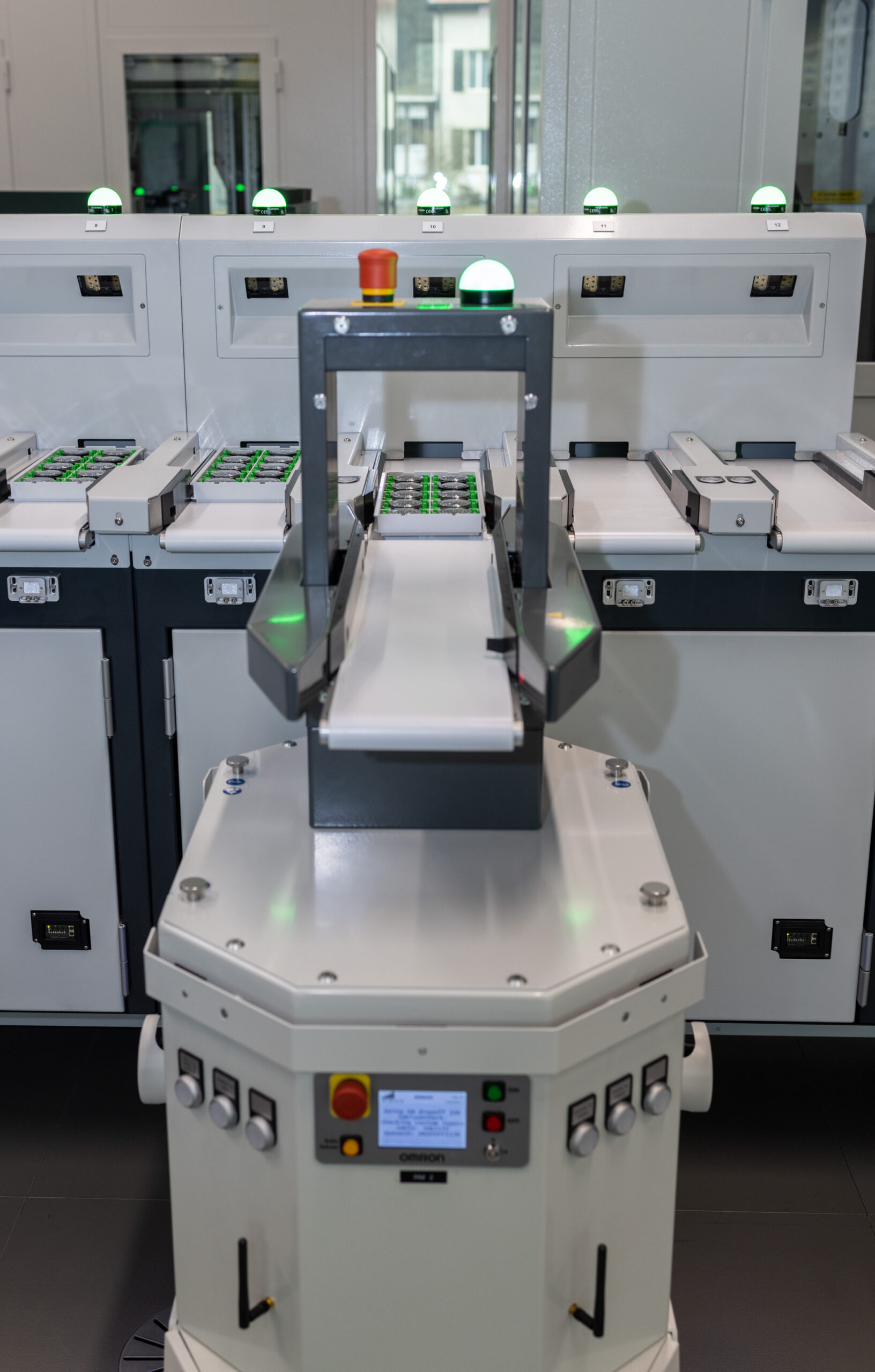

Robots, be they arms or sort of Dalek-like delivery bots make up an interesting portion of this stage, and it's neat to experience the cross-section of modern manufacturing processes against the backdrop and environment of Swiss watchmaking.

A specialized robot delivers a tray of Black Bay Ceramic models to a collection area.

This is the testing floors anti-magnetism rig, which is capable of testing a group of METAS chronometers up to 15,000 gauss.

The special tray that carries the METAS Chronometers into the anti-magnetic testing machine.

Finally, the watches reach the last stop, where a group of watchmakers completes a full check of the watch and its functions, coordinates any request for engraving, and fit the bracelet or given strap. Interestingly, the engraving is laser-based and you can actually do some pretty wild designs...

This caseback is not wearing hockey pants.

After seeing so many robotic arms carrying out specific processes, it was fun to see a real human fit a fresh bracelet in just a few seconds. I wish they had been offering classes as it takes a special touch to fit a Tudor bracelet without causing any scratches (and let alone doing it with a complete bracelet that is also wrapped in plastic for delivery). Really cool.

Fitting bracelets and other straps.

Look, if you know me and what I love to write about, you'll know that I've offered a lot of praise to Tudor over the past decade. I enjoy the watches that they produce and have even put my money where my mouth is with the recent purchase of a Pelagos 39. As such, it was a special treat to get a tour of the Le Locle facility and to meet some of the people that are actually assembling their watches. My watch, even.

Getting back on the bus to head back down to Geneva, the new Tudor facility underlined one major concept for me – maturity. While I don't think there is anyone out there claiming that Tudor should keep its distance from Rolex, it's clear that Tudor has been incredibly successful over the past 15 years and that success has afforded the brand a bit of breathing room. That independence could signal many things.

Perhaps that means increased production, and it almost certainly means a continued push toward more METAS Chronometers in the lineup. But it also means that Tudor can protect its price point, its production, and its supply chain in a manner that sets the brand up for continued success, especially when it comes to actually getting Tudor watches on the wrists all over the world.

Pre-Owned Picks Five Rolex Watches Under $10K That Are Available Without The Wait

By Mark hackman

Hands-On The Tudor Black Bay Burgundy, Now A Master Chronometer

By Anthony traina

Seven Of Our Favorite Watches From Past Masters Winners

Hands-On The New Rolex Daytona

Top Discussions

Business News Rolex Seeks To Expand Production With A New Factory In Bulle, Switzerland

Introducing The King Seiko KS1969

Introducing Hublot's First Collaboration With Artist Daniel Arsham Is A Droplet-Shaped Pocket Watch

Last Week’s Top Stories

Introducing The Audemars Piguet [RE]Master02

By Mark kauzlarich

Introducing Credor's Revival Of The Locomotive, A Long-Overlooked Gerald Genta Design (In-Depth, Live Pics)

Introducing The Audemars Piguet Mini Royal Oak

By Malaika crawford

Just Because Ever Wondered How Much A Patek Philippe Grand Complication Costs? Patek Finally Published All Their Prices

Pre-Owned Picks A Zenith-Era Rolex Daytona, A 1957 Trilogy Speedmaster, And A Distinctive Take On A Perpetual Calendar From Patek Philippe

By Hodinkee

THE HOME OF WATCH CULTURE

Dreams really do come true: My visit to the Tudor Manufacture in Geneva

Having joined the Time+Tide team during the pandemic, the tantalising prospect of travelling to watch events and industry launches was for a long time taken off the table. Instead I was bound to my chair, where I would sit writing each day for hours until I became worried that my skin would actually graft onto it. Sure, I felt some benefits of being on the inside lane, having press releases sent to me before new releases and doing the odd Zoom interview with industry movers and shakers. But my dream was always to go to Switzerland and visit some of the brand headquarters and watch fairs in person. Fortunately my time finally came a few weeks ago when I travelled to Geneva Watch Days. That was an amazing experience in itself, but a major additional highlight of my trip was being one of the first journalists outside of Switzerland to visit the Tudor Manufacture in Geneva.

My grandfather was one of the first sports agents here in the USA and so, at various points in my life, I had the good fortune of meeting some of his NBA clients. I remember when I met some of these individuals as a child, I would have to hold my neck as far back as I could to meet their gaze – straining to look up at their faces due to them being near seven feet in height. That sensation was akin to how I had felt looking at the Rolex/Tudor building. It is absolutely massive, like an Avengers facility built by Tony Stark. It further cemented the giddy feeling of childlike wonder that I had, like those moments when I met some of my basketball heroes. I mean I was effectively staring at the Buckingham Palace of watchmaking, where the Crown pumps out the highly sought after products that buyers have chased throughout the past, present, and for the foreseeable future as well.

Inside everything was state of the art, but nothing overwhelmingly ostentatious – it had that air of quiet professionalism the Wilsdorf brands exude. Floor to ceiling glass windows let ample natural light into the building, a must-have for the morale and performance of the watchmakers. After badging through the entrance we were guided to the Tudor Conference Room, passing by marketing and communications personnel. I was glad to see the work of Atom Moore gracing the walls, photo-collage works only a super photographer and watch enthusiast could create. One blended a vintage Black Bay with a modern version for an interesting side by side comparison, the other featured a Black Bay diver where bezel pips ran around the circumference of the watch creating a sort of dartboard effect (my personal interpretation: that Tudor never misses with its Black Bay novelties).

View this post on Instagram A post shared by Time+Tide (@timetidewatches)

In the conference room, the history of the brand graced the shelves. The marine nationale kits that inspire the modern day fabric straps, vintage Tudor divers I would love to have in my own collection, Lady Gaga’s pink Super Bowl helmet, and many more trinkets from their various ambassadors and their rich historical archive. It was like a mini-museum, and it felt very strategically placed in that this conference room is clearly a point of internal and external discussion about the brand’s direction. By having these objects present, it was a reminder of the heritage to be maintained as well as the “born to dare” mentality of today. After chatting for a bit, I was so happy to have a chance to get hands-on with some of the newer releases once again. But the real awe-striking moment was getting to carefully interact with the piece unique Tudor Black Bay GMT One for this year’s OnlyWatch auction – one of the many privileges of being able to visit Tudor in-person.

The next stop was the movement assembly floor, but we first had to follow procedure and carefully suit up before entering the assembly space. First we each had to step on this 3M sticky pad to remove any unwanted dust and debris from our shoe soles, agents of chaos if they found their way into the assembly room. We then put our white watchmakers’ coats on, followed by carefully wrapping our shoes in little booties. It was a bit of a dance, as the bench where you put these booties on served as a boundary where anything past it had to be lab-clean. I put one cover over my left shoe before placing it on the other side, then, straddled like a cowboy on the widest horse, cautiously placed the cover over my right shoe without the bootie hitting the ground until it was secured.

When I had applied for the Patek Philippe watchmaking school years back, I got a sense of what a watchmaking facility looked like. But walking into the floor where a mass of watchmakers took their places each day on various islands (as the factory refers to the sections of watchmakers) was a very different environment. I mean it was vast, but the real takeaway for me in this regard was how, even in this larger mass manufacturing space, the industrious aura is more human than you might imagine. While processes are optimized and streamlined for the utmost efficiency, understand that human craftsmanship and skill are still a large driving force of the final product on your wrist. As an example, I watched one watchmaker proceed to assemble manufacture calibers in sequence. She was assembling 10 of the same caliber at once – a carousel with 10 slots would rotate as each part was added to a mainplate/bridge, so the same component would be added to 10 different calibers before moving onto the next lap with the next component in sequence. It was a clear marriage of human and machine, the machines working to aid the human element of watchmaking rather than the other way around.

The main purpose of our visit was actually to see how the METAS master chronometer certification worked, and I was astounded at the lengths Tudor has to go to award their watches with such a certification. Prior to testing, the watch must pass the following criteria: Swiss Made, Certification by the Swiss Official Chronometer Testing Institute (COSC). Then the watch must display precision at two temperatures, in six different positions and at two different levels of power reserve (100% and 33%), smooth functioning when exposed to a magnetic field of 15,000 gauss and precision following exposure, 200m water-resistance (660 ft) in accordance with ISO standard 22810:2010, a 70-hour power reserve, and regulated performance within a 5-second range of variation each day (0 +5).

Tudor had to build out an entire section of the floor to create a separate space where the water/pressure, timing, and anti-magnetism testing could be preformed to the METAS standard, with the majority of the space inaccessible to even Tudor in order to maintain the principles of independent testing. Only select METAS officials have a key to the space, and at various points they visit the manufacture to test their own samples of the watches to ensure they are meeting the necessary criteria.

Overall I really felt like I’d won the golden ticket to Willy Wonka’s chocolate factory, a wide-eyed Charlie amazed with all the horological wonders throughout. It was my last appointment during my time in Geneva, so I really ended my journey with a bang and it really drove home the fact that Zach the enthusiast is a full-blown watch journalist now. Despite being part of the team for over a year now with hundreds of articles under my belt, it was moments like this where I understood my journey in this industry was really just getting started.

aBlogtoWatch Monthly Giveaway

Win: Bausele Royal Australian Air Force Centenary 2021

Building Traditional Watches Today: A Visit To The Tudor Manufacture In Switzerland

The scene was not typical even though the activity inside was routine for the region. Men in trim blue suits buzzed around as robotic arms and conveyor belts whizzed around watch parts. A watchmaker carefully eyes a dial under a magnification loupe looking for blemishes, and an industrial appliance that could easily double as a Star Wars droid ferries a tray of timepiece cases to their next station. This sci-fi combination of humans and machines is the latest and most ambitious effort to produce traditional mechanisms using some of today’s most sophisticated assembly-line technology. It helps keep costs down and quality high, and it is how Tudor makes its watches today.

In 1926, Rolex set up sister brand Tudor as a consumer entry point into watches. For years, Tudor watches were produced to be sold alongside Rolex, or in other retail channels, with Tudor always remaining a high-value, lower-priced alternative to Rolex timepieces. Tudor products have taken on a few different personalities over the years but until now have never been produced at their own dedicated facility. Now, that has all changed. This year, Tudor opens up its first-ever manufacture, and aBlogtoWatch was there for the first media tour. The facility is ultra-modern and represents one of the Swiss watch industry’s most ambitious approaches yet to marrying traditional artisanship to modern engineering and manufacturing excellence.

Like Rolex, Tudor is officially headquartered in Geneva but now has its production facility elsewhere — in LeLocle, Switzerland (Rolex produces its movements in Biel/Bienne). Le Locle is a historic watchmaking town in Switzerland and is home to a number of other watch brands and movement-making facilities. It is now also home to the Tudor Manufacture and companion Kenissi movement production company, all under one roof. It represents a strengthening of the Tudor brand, along with a move toward more independence and less oversight from Rolex directly. While top-level company decisions still involve Rolex, today, Tudor is running things its way more than ever.

Part of running Tudor today is also running Kenissi, a separate company that produces mechanical watch movements. Kenissi operates as a supplier to a growing number of watch brands and began alongside the development of movements designed for Tudor brand models in 2010. Tudor and Rolex made the decision that the development of the new Tudor calibers could be applied to the creation of base movements which could be sold to third-party companies. Tudor unveiled its first in-house movements (entirely different from Rolex movements, and also not like the ETA movements previously used in most Tudor watches) in 2015. A year later, in 2016, Kenissi was formed.

Kenissi accepted a 20% purchase stake from Chanel in 2018 in order to jointly take on the mission of developing the manufacturing capacity of the new movement-making company. Accordingly, Kenissi movements are featured in many Chanel timepieces. Otherwise, Kenissi is controlled by Tudor — perhaps a given being that it is where Tudor’s movements are produced. The new facility in Le Locle is split between the Tudor and Kennisi areas, but the operation of the companies is intertwined. There is real excitement in the air because all of this is very new to the Rolex family. After nearly 100 years in existence, Tudor is finally out on its own a bit, and with its newfound independence is the important responsibility of ensuring movement production efficiency, one of the absolute hardest things to master in the area of watchmaking. The idea is that it is easy to produce a small number of watch movements if you have lots of time. Alternatively, it becomes very difficult to produce a large number of watch movements in a short period of time — if you aren’t armed with “The Rolex Way.”

I’ve been to where Rolex produces watches and have been able to compare and contrast it with the Tudor Manufacture. Much of the same philosophy abounds, namely the use of automation to assist human effort in order to promote quality (more so than costs). The reality is that designing, building, and maintaining a watch factory that employs robots and a large amount of automation is hugely expensive. What Tudor gains from this extremely modern approach is speed and efficiency. It affords the brand the ability to produce very high-performance watch movements quickly and consistently. Tudor now produces many of the watch movements used in their timepieces and openly relies on a mixture of third-party suppliers for the rest of its watch components. Some of the entry-level Tudor watches – for value purposes – contain Swiss Made ETA movements. The in-house Tudor movements aren’t just “Swiss Made,” but made from parts that are all manufactured in Switzerland. All the Tudor watches that contain in-house movements will eventually (there is no specific date in mind, but it is a goal that Tudor is working toward) also be certified as Master Chronometers.

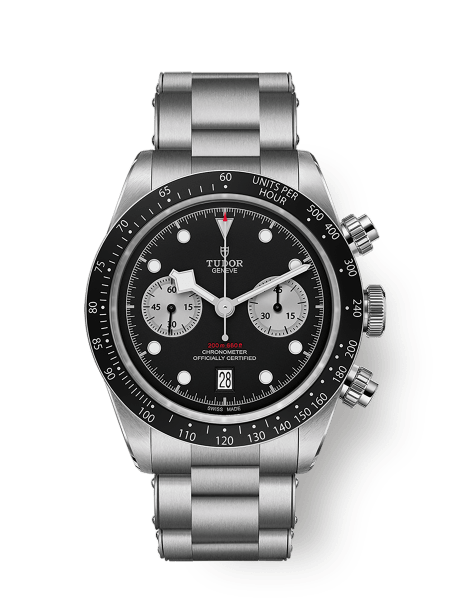

Currently, only a small number of Tudor watches are given METAS certification and are thus considered to be “Master Chronometers.” The designation is far more meaningful than COSC Chronometer certification, if only because it tests for more serious reliability and occurs when a movement is actually inside the fully-cased watch (COSC only tests bare movements). METAS certification also tests for important things like magnetic resistance, which Master Chronometers excel at given their a-magnetic movement parts. Tudor has set up a full METAS certification section at its factory in anticipation of more and more of movements bearing this important certification standard, which, until recently, was only used by Omega. The prospect is exciting for Tudor fans and consumers who have high performance expectations from their timepieces.

The reason I feel most watch lovers should be interested in the Tudor Manufacture is specifically because it isn’t trying to be about luxury. This is a place for machine and construction nerds. It is a place where you can get excited about the innovative and rapid way the building was designed and constructed to be efficient and friendly. It is a place where you can marvel at how extremely sophisticated tools and systems are used to track and move watch parts around so that humans can maximize their time doing actual watchmaking. The entire factory is a lot like a watch mechanism itself. Tudor has designed it to, as autonomously as possible, take in raw components and put out high-quality watches. It is a marvel and Tudor/Rolex are true masters of this game. In the Swiss wristwatch world, there is very little out there like it.

The Tudor/Rolex Way is really a method or approach to design, manufacturing, and operation. It is applied to watches but can really be applied to almost anything that is constructed. The Tudor Manufacture itself and the product assembly system within it is a perfect example of that notion in action. Tudor demonstrates an honest commitment to its brand by creating something world-class and very contemporary but that doesn’t overshadow Rolex or needlessly increase costs for consumers. The resulting feeling is that Tudor’s products are extremely carefully made but also not priced higher than they need to be. Value is increasingly becoming important for watch buyers around the world, and brands have a duty to fully explain how and why their products are worth it. Tudor has been on a roll in this department, and the addition of the dedicated Tudor Manufacture appreciably adds to the brand’s prestige as well as legitimacy in being its own brand outside of the looming Rolex shadow.

Tudor is making market gains across the world, as it has steadily been doing since the brand was revitalized a few years ago. Much of the company’s marketing is to younger buyers and those not yet ready (or able) to purchase a Rolex watch. That makes sense, but young or new watch buyers are hardly the only people who can appreciate what Tudor is doing. Collectors and enthusiasts are increasingly interested in Tudor because of its strong tool watch offerings with increasingly high-performance movements and modern takes on classic sporty designs. Mature wearers are choosing Tudor timepieces as weekend or even daily wearers because of their accessibility and approachability. To be equally compelling to novice and seasoned timepiece enthusiasts alike is a very uncommon position for any brand to be in – and yet Tudor has perfectly aligned itself for success in this position. It will still take a few years before your average watch buyer fully understands today’s Tudor story, but once they do, the relationship they will form will be lasting. Learn more at the Tudor watches website .

Inside Tudor Watches: behind the scenes at the home of the accessible luxury watch

Luxury and accessibility don’t normally go hand in hand, but through a combination of efficiency and experience, tudor has managed to seamlessly merge the two. ben winstanley enjoys a rare behind-the-scenes tour of the brand’s geneva hq, by ben winstanley.

Photo by Fred Merz

Published: Tuesday 24th March 2020

The Grand Prix d’Horlogerie de Genève, otherwise known as the ‘Watch Oscars’, is every bit as important to the world of horology as the Academy Awards are to the film industry. They’re not as fun or as Britain-focused as the Square Mile Watch Awards (we’d consider ourselves the BAFTAs of the circuit, naturally), but the GPHGs offer watchmakers all-important bragging rights in a sector where prestige means everything.

Winning one of these bad boys isn’t necessarily conducive to a best-selling timepiece, in the same way that plenty of Oscar winners have bombed at the box office, but swaying an international panel of 30 watch experts is no mean feat.

One brand that has made a particularly strong impression on the jury over the last decade is Tudor Watches . When CEO Éric Pirson stepped on stage in 2019 to collect the GPHG’s Challenge Prize (awarded to the best watch under 4,000 CHF, on this occasion going to the Black Bay P01), it was the fifth time in seven years that his brand had taken home a gong. Not bad going for a watchmaker that has for too long lived in the shadow of its ‘big brother’ Rolex.

Sibling Rivalry

When Hans Wilsdorf created the Montres Tudor SA Company in 1946, 38 years after founding his first Swiss watch giant, he did so in a concerted effort to offer timepieces with the quality and dependability of Rolex at a more accessible price point.

It was a simple but effective premise that relied on appealing to the working man as opposed to the elite: ‘Shock treatment at the coal face’, ‘3 months’ hammering!’, ‘Punished without mercy!’ read the early newspaper advertisements – each displaying the Tudor Oyster Prince as a watch ready to tackle the rigours of daily life alongside their blue collar owners; Rolex may have stylised the tool watch, but Tudor distributed it to the masses.

Photo courtesy of Tudor's archives

Like every second child, however, Tudor’s journey to wrench the spotlight off its successful sibling has not been a straightforward one. After all, it’s never easy to make yourself heard when big brother is responsible for cornerstones of watch design like the Explorer, Daytona, and GMT-Master.

For Tudor, much of its early identity revolved around being the more accessible add-on to its affiliate company. On occasion, it even aped its kin in an effort to bring these icons to a wider audience – the Submariner, for example, was first showcased by Rolex in 1953 before Tudor debuted its own version a year later, keeping the Submariner moniker but replacing the Rolex calibre for an outsourced movement to keep costs down. Both designs are now recognised as classics of their time, with lofty auction prices to match, but it is the Rolex for whom the Sub will forever be immortalised.

Tudor has always made great value watches, but today they have widespread appeal too

View on Instagram

In recent times, the sibling dynamic has shifted somewhat as Tudor has asserted itself as an influential presence in the watch world in its own right, thanks in part to two significant developments: first, the release of the Black Bay collection in 2012 – which, it would be fair to say, has already reached icon status – and the production of its first ever in-house movements from 2015.

The brand’s exciting output of timepieces since then, including the Black Bay Bronze (one of the first pieces to adopt the bronze metal trend), the Black Bay Chrono (a superbly designed chronograph), and 2019 GPHG winner the Black Bay P01 (a wholly unique dive watch) showcase Tudor as one of the most potent creative forces in the modern industry. In the hands of lead designer Ander Ugarte, it shows no sign of tempering the enthusiasm of journalists and watch collectors alike.

Tudor may have always been one of the leaders at the accessible luxury portion of the market, but today its appeal is more widespread. You need only look at the brand’s ambassadors – David Beckham, Lady Gaga, the New Zealand rugby team , and more – to see how times have changed. It’s a far cry from the blue collar workers pictured in the brand’s formative advertising. Buying a Tudor is no longer a financial compromise, but comes down to whether you associate with the brand and its ‘ Born To Dare ’ lifestyle: it’s bolder and a little more roguish than the distinctive luxury of Rolex, and for many that’ll do nicely.

Kid brother is all grown up.

The Making of Tudor

There are some things that don’t change. Tudor may have risen up the horological hierarchy in recent years, but it still shares its Geneva headquarters with Rolex; all the family under one roof.

Located a short way from the Rhône river and the city centre beyond, the glimmering glass complex takes up a full block – encompassing corporate offices, separate design, research and development departments for each brand as well as vast production units (some of which stretch into the basement levels below). Hell, there are also five restaurants to choose from, including a fine-dining offering, for the building’s 2,000 employees.

Such is the size and scale of this watchmaking behemoth that the Rolex company is the single largest private employer in Geneva. If you’re from this town, you either have a friend or family member who works here, or you do.

The mind boggles at the speed with which these watchmakers work to meet demand

Armed with this knowledge, you may be surprised to learn that Tudor’s footprint within the Rolex building is incredibly small for a brand that has a sizeable output of watches a year. Every Tudor watch that comes to market is assembled in a single workshop where just 80 people take a timepiece from a smattering of individual components to the final product.

There are various facilities dotted around Switzerland where components are manufactured and assembled, but the final movement assembly, the casing, dial- and hand-fitting, and rigorous quality control checks are conducted in a room no larger than a football pitch. The mind boggles at the speed and diligence with which these skillful watchmakers must work in order to fulfil growing consumer demand.

Highly advanced machines designed specifically for Tudor expedite particularly time-consuming tasks like the hands fitting

Tudor employs the Japanese work philosophy kaizen – incrementally improving each stage of the watchmaking process. For example, using custom-designed work benches.

Nothing is left to chance: Tudor employs the Japanese work philosophy kaizen in order to incrementally improve each stage of the assembly process for maximum efficiency. Customised work benches, complete with specific drawers and compartments for individual tools, allow workers to reach for the required instrument without a moment’s hesitation; highly advanced machines designed specifically for Tudor expedite particularly time-consuming tasks like the hands fitting; while the fight against dust (the watchmaker’s mortal enemy) is managed by a sophisticated air flow system which includes employees walking through two airlocks to get into the workshop. Even the lab coats you have to wear in the room feature subtle magnetic black lines that attract dust. It’s an obsessive compulsive’s wet dream.

To give one example in a room of countless little victories in the quest for absolute efficiency: components are robotically transferred from the stock room (known as ‘the church’ among employees, owing to its dizzyingly high ceiling) to the workshop.

Orders requested by the logistics team on the computer arrive in less than a minute, before being checked and distributed to the appropriate watchmaker. These orders are dictated by the digital catalogue of each specific component’s inventory number to ensure no worker finds themselves waiting for logistics to call up a given part. It might seem mundane, but it’s one small cog in an exceedingly well-oiled machine – without it, your shiny new Tudor would have a higher price tag due to a slower assembly process.

Diving Deeper

The Black Bay collection is Tudor’s leading light and chief moneymaker. It carries in its DNA the brand’s historic association with dive watches (reaching back to the Submariner), as well as its reputation for high quality reliable timepieces. So to say that the workshop’s waterproofing station is a vital part of the assembly process would be something of an understatement.

Every watch is subjected to fastidious water tests: first being submerged in a pressurised tank to measure water-tightness (dive watches are subjected to three hours of pressure, in comparison to a measly 20 minutes for your standard dress watch), and secondly a thermal test whereby a single drop of cold water is applied to the sapphire crystal of a heated watch. Failures along the way may be particularly obvious or more difficult to spot with the naked eye. Even if the crystal doesn’t appear broken, if the glass steams up during the thermal shock test it isn’t waterproof, which means it’s time to start over. Pass the examination and the watch is fitted with its strap or bracelet and ready for its final once-over before being distributed to retailers.

Put it to the test

Everything from the resilience of the NATO straps to the ageing of the manufacture calibre is strictly monitored in Tudor's advanced R&D facility.

The 2015 launch of Tudor’s first in-house calibre brought with it a need for further movement testing in its R&D lab. The team here is part engineer and part watchmaker in their forensic approach to preparing a watch design for production.

Newly launched movement designs go through several stages before they can be scaled up. The first step is simulating the mechanical function of the movement on digital software to illustrate proof of concept. Next is the prototyping phase where between 50 and 200 movements will be tested to ensure they can withstand the rigours of even the most reckless owner – these destructive trials include using lasers to test the wear and tear of each movement component, salt-water resistance, extremes of temperature, bracelet resistance, clasp resistance, shock resistance, and testing a movement for three, five and ten years of accelerated ageing. By the time the watch reaches the production stage, any fundamental issues have been ironed out.

Building Something New

“The Black Bay was special because before drawing it, I went to the archives and looked at all our old diving watch collections – and, as a result, it’s kind of a mix of all of them. It’s a process of trying to learn from all of them, all of the details they have inside, then trying to forget all about it and build something new.” Tudor’s lead designer, Ander Ugarte, is responsible for one of the most successful collections of the last decade, and at least partly to thank for the brand’s current standing in the watch world. As he explains his process from a kernel of an idea to a fully fledged design, it’s difficult to lose sight of the fact that this is a master at work.

The Spaniard studied design in Italy before doing an internship at Rolex in 1990: “I was only supposed to be here for 12 months, but 30 years later I still haven’t left!”

Entering Ugarte’s office is to step into the mind of the designer. His mood board is full of posters and photos of vintage bicycles and airplanes; there are blueprints of old Tudor designs; and even a 1980s Techni Ski (like a monoski skateboard) he picked up from the flea market next door. It screams creative.

So how do you design a new Tudor? Let’s take the award-winning P01 as an example: the starting point was the turning bezel mechanism of a scrapped prototype developed for the US Navy in the late 1960s. Ugarte hand-sketched his version of this mechanism before digitally creating it on a 2D illustrator. Here, he can create a layer for each design element (different options for the hands, different engravings, alternative graphic elements on the bezel), and take his idea to the management board for approval.

To maintain secrecy, each new model has a codename. The P01’s? Project Saturday

Next stage is 3D construction whereby each element of the watch – from the dial and bezel to the hands and end links – is digitally created before the whole piece created in resin using a 3D printer. This way, the team has a view of the proportions and can see if there are any elements that might not work.

Tudor’s modellist then works closely with Ugarte to build the first timepiece. Practical issues are sorted at this stage: for example the clasp of the leather didn’t quite work in the original format and was improved before the design was greenlit for production.

The whole process can take anything from months to years to realise an idea, which is why Tudor has an ever-evolving five-year roadmap for future releases. To maintain secrecy each model is given a codename. The P01’s? Project Saturday.

Wrist and Reward

Tudor Watches: Sharing Secrets From Inside the Factory

Justin Mastine-Frost June 26, 2023

In the luxury watch market, few brands are quite as secretive about their manufacturing and production operations as Tudor Watches. Being the sister brand to Rolex has its perks in terms of resources, R&D capital, and so on, but in trade much of the brand’s operations are kept behind closed doors — at least until very recently. To celebrate the inauguration of its brand new manufacture, Tudor recently invited select press from around the globe for a tour of the new facilities.

Arriving in the hills of Le Locle — the same watchmaking mecca home to the likes of Zenith and Ulysse Nardin — Tudor’s new space is both far from home, and right where it should be. Prior to this, Tudor occupied the space adjacent to the Rolex headquarters in Geneva, further cementing its position as living in its big brother’s shadow. In its new location, the brand is a stone’s throw from its supply chain, which in turn keeps its production and assembly processes much more seamless.

What’s especially interesting about Tudor as a business model is how the brand tackles a mix of what one might call diagonal integration. On one end of the spectrum, half of the building houses the Tudor-owned movement manufacturer known as Kenissi. The movement manufacturer is responsible for supplying all of the in-house mechanical watch movements that power Tudor’s watches, all while selling a small percentage to outside sources, including TAG Heuer and Bell & Ross.

When it comes to the balance of its watches — dials, hands, cases, and so on — Tudor relies on a network of suppliers. This method is the norm across the vast majority of the industry, however, Tudor being Tudor (and Rolex being Rolex), the brand has a slightly different approach. Every component supplier that Tudor uses is either fully owned or majority-owned by Rolex/Tudor. This ensures that the brand takes top priority when it comes to its supply chain, and that it has the ability to make requests and set requirements in a manner that simply wouldn’t be possible with an unowned third party.

Tudor factory

Walking through the doors of Tudor and Kenissi for the first time, it was challenging to gauge what to expect. On one hand, once you’ve seen one watch manufacturing facility it’s a lot of the same, but the unique position of Tudor as a luxury value proposition with Rolex-level standards changes the equation quickly. Due to the supplier integration, there’s little in the way of true manufacturing taking place, for one. Big as the building is, the Tudor and Kenissi facilities are assembly plants more than anything.

Even in that respect, Tudor does things a bit differently than what’s seen at other brands. You’ll often see top-tier luxury watch brands where the assembly of a watch and its mechanical movement is completed by a single watchmaker. At the entry-level end, you’ll see more of an assembly line method, where each watchmaker is trained in a particular step of the process. At Tudor, it’s a bit of both.

In Tudor’s main assembly area, there’s an array of workstations where its highly trained staff work on installing dials, hands, and completing other final assembly stages. Though each workstation is different, all of Tudor’s watchmaking staff have been trained in each step of the process and can complete the work on any of the brand’s roughly 700 catalogue references. Each team member is a specialist in all things Tudor, which ensures that no matter what happens there are team members in the room available to keep the production line moving.

Being a brand new facility, there’s little surprise when it comes to the level of automation in the room. From the brand’s secretive parts storage vault (the one room of the building where no photography is allowed) to the extensive testing and quality control department, a healthy assortment of robotics are deployed to keep processes smooth and standardized. Perhaps in part out of novelty, there are even a pair of roaming droids used to move trays of completed watches between testing stations.

Given Tudor’s explosive popularity in watch collecting circles over the past decade, all of this focus on efficiency and keeping product moving is of little surprise. Just like big brother Rolex, annual production figures are kept quite hush-hush, but between the size of the location and the fact that it runs as a “zero stock” facility (with all watches heading straight from Le Locle to distribution and retail), it’s safe to say that business is good. With the quality of the product we’ve seen and the legacy of being “the Rolex for the people,” it’s easy to see why.

Be SHARP Get SHARP

5 issues, 1yr. only $17.85

YOU MAY ALSO LIKE

SHARP Drives: The Screen-o-licious 2024 Lincoln Nautilus SUV

The Michelin Key: Unlocking Top Hotels Across USA, France, Italy, & Spain

Keep Your Chin Up: Restylane SHAYPE

Playing to Win: Félix Dolci Talks Olympic Debut & Shows Off Men’s Summer Style

200 Years In, Fettercairn Distillery Is Still Keeping It Local

A Closer Look At Jeep’s First EV, The Stealthy Wagoneer S

Podium-Worthy Performance

A Letter From Our Managing Editor: Good Sport

Chris Hemsworth Talks Stunt Work, Discipline, & His Fitness App, Centr

Find anything you save across the site in your account

Inside Tudor’s notoriously secretive watch factory

By Charlie Burton

The Rolex building in Geneva might be clad in glass, but don’t be deceived: it’s a fortress. The watch brand and its sibling company, Tudor, which is also headquartered here, are notoriously secretive. Details about their manufacturing operations are scant; their finances are a private matter; and future launches are kept ruthlessly under wraps. The mystique only adds to their allure. Today, however, Tudor has invited GQ inside its section of the campus to see how it designs, tests and assembles its watches – a golden ticket to Willy Wonka’s factory.

To understand why Tudor may wish to open its doors, you need to understand its heritage. The brand was set up by Rolex founder Hans Wilsdorf in 1926 to offer a Rolex-quality timepiece at a more accessible price. Its early advertising billed Tudor firmly as a watch for the working man, depicting coal miners, stone masons and construction workers alongside straplines highlighting durability: “Shock treatment at the coal-face”; “Punished without mercy!”

Rolex and Tudor evolved side by side, sharing innovations, components and even model names – until 1999, for instance, Tudor sold its own Submariner – but the Tudor brand lost its appeal around the turn of the -millennium and in 2004 was discontinued in America. Six years later, however, Tudor released the Heritage Chrono, firing the starting gun on a full-scale relaunch. This watch, like those that followed, warmly embraced the design language of Tudor’s past. The effort caught the eyes of vintage enthusiasts and proved a resounding commercial success. Three years later, Tudor relaunched in America and today the brand is enjoying renewed popularity around the world.

Yet, for some would-be buyers, questions linger. Is a Tudor really as reliable as a Rolex? What is the manufacturing relationship between the brands? And how exactly does Tudor keep those prices down? Today’s tour seems designed to put all that to bed – and this transparency resonates with Tudor’s new core frequency of straightforwardness.

In that spirit, we begin our tour right at the nerve centre of Tudor, in the room where members of staff known as “conceptors” come up with new movements. Some Tudor references beat with third-party calibres, but certain models, such as 2015’s Pelagos, are powered by in-house creations. All of that work begins here on computers, using a software package called Creo – and cost is kept in mind every step of the way. Hence Tudor’s debut MT56 group of movements, which has been designed as an easily adaptable platform to accommodate whatever complications a model may require.

That’s not the only cost-saving measure inside the watch. Look at the components, which are made of industry-standard surgical-grade steel (Rolex uses its own more expensive alloy). The decoration of a Tudor movement is also much simpler and the accuracy falls within a fractionally larger range. The Contrôle Officiel Suisse Des Chronomètres (COSC), which certifies the accuracy of timepieces, requires that a calibre does not gain more than six or lose more than four seconds per day. Rolex watches meet those criteria and then some: its watches are accurate to plus-two, minus-two. Tudor on the other hand keeps to plus-four, minus-two. That might not sound like a dramatic difference, but every additional second’s accuracy requires an exponential increase in investment.

By Mike Christensen

By Charlie Thomas

By Finlay Renwick

While in these respects Tudor and Rolex movements diverge, both companies test their prototypes the same way. In a lab just a few metres from Tudor’s conceptors, designs are put through their paces using identical processes and equipment to the sister brand – indeed, many of the machines here bear the Rolex logo. The common goal of the machinery is to artificially age prototypes and see how they fare. So, there’s a device that rapidly twists the winding stem, another that repeatedly sets the date and one that pushes and pulls the crown – some of these simulating up to 27 years of use. Elsewhere on the premises, there’s a room shared by Tudor and Rolex where prototype watches are subjected to shocks – dropped from heights, smashed with hammers – to make sure they can survive even the most careless owner. The only time Tudor uses its own dedicated equipment is to test unique functions, such as the alarm on the Tudor Heritage Advisor.

If the ageing lab is about destruction, the room next door is about creation. Remarkably, given its lounge-size proportions, this is where every in-house movement used in a Tudor is assembled, before going upstairs to be cased up into a watch. It arrives on that upper level alongside the other required parts, such as case, hands and dial, ordered in from third-party suppliers. Tudor doesn’t keep stock – another cost-saving measure – instead making all its watches to order. If there are peaks in demand, workers are brought in from Rolex to assist with assembly. If more in-house movements than usual are required, this work is outsourced to external workshops.

The sizeable assembly floor is sealed and pressurised like an aeroplane to minimise airborne dust and the space is divided into separate groups of workers that organise their tasks autonomously: at the start of the week they assess how many watches they need to produce and divide the labour accordingly. Each person has a workbench supplied by the same company that kits out Rolex’s assembly rooms. These are organised in line with a Japanese production methodology known as “5S”, which dictates that work stations should be furnished with the minimum necessary tools and that each tool has its own dedicated location: for that reason the drawers are labelled with outlines to show which one goes where.

The technicians have plenty of machinery to help them do their work quickly and accurately: a robot that finds the midnight position on a dial before fitting hands; a device that affixes dial to movement with the correct amount of pressure; electric screwdrivers that apply a specific amount of torque. But human input is vital every step of the way. After the hands are fixed, for instance, a technician adjusts their relative height by eye and the in-progress watch is inspected repeatedly for dust and flaws. If anyone spots a problem, it is easy to trace back up the production line to identify the person responsible (no pressure).

Finally, before the watches are attached to bracelets and packaged up to be sent to retailers, their waterproof credentials are assessed. This is a three-step process: first the cases are examined for air-tightness – well, you don’t want to wreck a leaky watch unnecessarily – and then they are submerged in a water tank and subjected to pressures equivalent to particular depths. If the watch promises water resistance to 100 metres, it’s tested to 110 metres; if it promises 500 metres, it’s tested to 625 metres. Once removed, the watches are heated to 55C and a drop of cold water is placed on the crystal – if any water has seeped inside, condensation will appear. Which other watch company uses this same approach? You got it: Rolex.

The omnipresence of Rolex throughout this tour invites a question: why buy a Tudor when for a couple of thousand pounds more you could actually buy a Rolex ? “Tudor offers a great level of quality at a price where Rolex has no offering, so we’re complementary,” says Tudor spokesperson, Christophe Chevalier. “And Tudor offer an opportunity for another profile of buyer to buy into our quality and watchmaking philosophy.”

In fairness to Tudor, there are also things it offers that Rolex does not. The bronze case of the Tudor Black Bay Bronze , say, which develops a gentle patina as it ages, is not something you’ll find on a Rolex. And indeed, Rolex does not offer any of its watches on a fabric strap. Since 2010, Tudor has done just that – and it went to great lengths to find a strap made with the same level of care and craftsmanship as its timepieces. That mission took Tudor over the border to Saint-Étienne in France, where the weaver Julien Faure is based. This factory was founded in 1864 and today it claims to be the last to use traditional Jacquard looms. Some are 150-year-old models, others are modern versions developed by Julien Faure itself. The Jacquard technique can achieve especially intricate designs, which is why major fashion houses from Gucci to Hermès and Louis Vuitton to Christian Louboutin count themselves as customers.

When Tudor approached Julien Faure, the weaver had never created a watch strap before. The development process was complex, particularly because the tunnels for the spring bars had to be woven into the design, meaning that each strap – which takes around ten to 15 minutes to weave – is effectively a work of 3-D printing. These creations, whether that’s the silk design for the Heritage Advisor or the camo number on the Heritage Ranger, have become Tudor signatures that set the brand apart.

If any proof were needed of how successfully the marque has rehabilitated itself through design decisions such as this and countless others, consider the Tudor Black Bay GMT that was released this year. Its design is remarkably similar to a Rolex GMT Master II. You could make the argument that eight years ago Tudor would not have released that watch, because customers would have shunned it for not being a Rolex. Today, it’s hard to get your hands on one. Why? Precisely because it’s a Tudor.

Get ready to lust over these insanely rare Rolex watches

What makes casemaker extraordinaire Jean-Pierre Hagmann tick?

Why Rexhep Rexhepi needs to be on your watch radar

By Jeremy Freed

By Vivian Morelli

By Oren Hartov

By Sam Parker

By Scarlett Baker

By Cam Wolf

Celebrate The Class of 2024

What Watch Manufacturers Can You Actually Visit?

Historically speaking, watch manufacturers love to keep things behind closed doors when it comes to production (both technique and volume, for that matter). However, the game has slowly been changing as consumers become more engaged and interested in how their goods of any kind are being produced.

Sure, you’ll still never get through the doors of Patek or Rolex to see what’s going on behind the scenes, but there are a number of noteworthy brands that have changed their tune and are allowing public eyes onto their manufacturing processes. If you inquire via your local boutique, there may be other brands able and willing to organize private tours for you (and a small group of fellow enthusiasts), but for now, those on the list below have made tours available for public consumption without having to befriend the local staff.

Announced this past September, IWC’s massive new 145,000 sq. ft. manufacturing facility located on the outskirts of Schaffhausen was actually designed with the consumer/visitor experience in mind.

IWC’s CEO Christoph Grainger-Herr was directly involved in the design of the facility (he’s a former architect by trade), believing that it was essential for the brand’s long term success to allow clients (and potential future clients) the ability to see, touch, and experience what goes into the creation of their watches. Unlike some other brands (as you’ll see later on), these tours will be frequent, as the brand expressed a lofty goal of welcoming over 10,000 visitors within its first year of opening.

A. Lange & Sohne

Though they also offer tours to the public, getting your foot across the threshold of the Lange manufacture in Glashutte – a small town about 45 minutes outside of Dresden, Germany – is a bit more involved than with IWC. They don’t specify the number of tours offered per month or per year, stating only that they are extremely limited.

These will have to be coordinated via your local AD, meaning that it’s a fair assumption that unless you’ve purchased a couple of their pieces, you might not have much luck getting a tour booked. Once past the gatekeepers, the experience will be worth the wait, as Lange is one of few watch brands out there to have a very extensive in-house manufacturing capability.

Another new addition to the list as of last year, Zenith’s approach is entirely in line with IWC’s as far as wanting to welcome as many guests/enthusiasts as they can. Jean-Claude Biver announced the idea in 2017, and their updated facilities (just like at IWC) are designed to make the visitor experience as comfortable and open as possible.

What’s more, the visit not only includes touring the manufacture, but also other educational experiences to give visitors a more well-rounded view of the brand as a whole. These tours last roughly three hours, and run every Friday morning at 9am.

Frederique Constant

A bit of a surprise on this list, located just outside of Geneva, the Frederique Constant manufacturing facility is an interesting one to say the least. Because the brand plays in a more approachable cost space, their manufacturing practices are a touch more industrialized, and yet you can see a level of attention paid at every step.

In order to streamline their movement manufacturing process, they have been doing an excellent job creating modular movements that are both straightforward and easy to assemble. Sure, this doesn’t sound as romantic as a single watchmaker toiling over a workbench, but watching the FC team assemble movements like a well-oiled machine is impressive in its own right. The brand’s sister company, Atelier DeMonaco also operates under the same roof, so in the same visit you’ll also be able to see their top-level watchmaking as well.

About Justin Mastine-Frost

With over a decade of experience as a journalist and editor covering the watchmaking, the automotive industry, and other lifestyle topics, a general obsession with mechanical creations remains the common thread. Having worked for a broad range of industry and general interest publications throughout the years, Justin has developed a sincere appreciation for a wide range of watch brands and styles, as well as an ever-growing interest in the vintage watch market.

Bob's Watches Blog Updates

Sign up and be the first to read exclusive articles and the latest horological news.

Bob's Watches / Rolex Blog / Resources

Recommended Articles

Forgotten Complications – Why I Miss The Triple Calendar Chronograph

Finance Your Rolex Just in Time for the Holidays

A Brief History of the Wristwatch – Part 1

You may also like.

Speedmaster

Omega Speedmaster 145.022 Stainless Steel

Rolex Datejust

Rolex Datejust 278381 Stainless Steel & 18k Everose Gold

Rolex Explorer

Mens Rolex Explorer II Ref 16570 White Polar Dial

To revisit this article, visit My Profile, then View saved stories .

- Backchannel

- Newsletters

- WIRED Insider

- WIRED Consulting

Inside Tudor’s HQ: how Rolex’s sibling is quietly transforming watchmaking

A visit to Tudor’s headquarters in Geneva is a visit to the heart of a paradox. For starters, there really is no such thing as “Tudor HQ”. What there is, in a light industrial district to the south-east of central Geneva known as Les Acacias, is Rolex HQ: a number of interconnected monolithic glass buildings laid out over two city blocks.

The ten-storey factory buildings stretch out forbiddingly, clad in darkly tinted glass with taller blue-green tower blocks at the entrance. In distinct contrast to its unassuming neighbours (a handful of car dealerships, an electrical wholesaler and a maker of fitted kitchens), it gleams spotlessly. The whole site is surrounded by neatly maintained lawns and planted with trees of completely uniform height and size; flagpoles line the driveway and atop each of the main buildings is a large yellow crown logo, with Rolex in green letters ten feet tall beneath them. The rooftops are either covered in grass or solar panels. You could walk around this miniature campus for hours, peering in vain at the opaque glassy slabs, without deriving the slightest hint that it was also home to another brand.

This will make sense to watch fans: Tudor was established in 1946 by Rolex founder Hans Wilsdorf with the explicit mission of providing watches for customers not yet well-heeled enough for Rolex ownership. It has always been a wholly owned subsidiary of Rolex and for years was marketed and advertised in the same catalogues.

It is a paradox for modern-day Tudor, however; having gamely played the role of younger sibling for several decades, the product lineup grew stale around the turn of the millennium, and the Tudor that emerged into the light in 2010 following a three-year process of rebranding is no longer a scaled down sidekick but a company with a vivid identity all of its own. That makes not having your own front door – let alone your logo on the roof – a bit awkward.

To many, Tudor’s one-line pitch is still “Rolex quality at lower prices”, and as selling points go, that’s not at all bad. But the reality is that modern Tudor has made a distinct habit of doing things big brother won’t, like limited editions and retailer collaborations, heritage revival models and working with materials Rolex’s conservative ethos doesn’t allow, such as bronze, ceramic and fabric straps (of which more later). And once you do penetrate the exterior of this green and gold temple to find the red and black Tudor-branded zones within, you realise the two brands really are doing things differently at every step of the watchmaking process.

Sometimes, that’s out of pragmatic necessity: Tudor’s value proposition makes it futile to attempt the kind of all-under-one-roof approach adopted by Rolex (which makes everything save for the hands and sapphire crystals, even going so far as to smelt its own metals). It buys in its dials, cases and bracelets as well as some movements; Tudor has been producing its own movements since 2015 but relies on third parties for some models – notably receiving chronograph calibres from Breitling in exchange for time-only movements. Tudor also takes a fundamentally different approach from Rolex in managing its production: whereas Rolex carefully controls stocks of its most sought-after watches, Tudor says it builds everything to order, an outlook that requires extremely efficient manufacturing practices.

By Boone Ashworth

By Simon Hill

By Henri Robbins

The facilities at Les Acacias don’t cover movement manufacture – the most complex and time-consuming part of building a watch – instead, that takes place at a site elsewhere in Geneva (soon to move to Le Locle as part of a joint venture with Chanel). But it is where the watches are designed and tested, and it is home to the final assembly workshops, where all the disparate parts come together to become watches. Managing that process requires careful co-ordination.

At the heart of the operation is The Church. Not a statement of faith – this is the nickname for the vast centralised vault of parts that forms the backbone of the assembly process. A fully automated system that holds millions of components over five subterranean storeys, it can deliver the necessary box of bits to Tudor’s assembly floor in less than a minute. The boxes arrive with the “train station” team, who manage the flow of parts in and out, and their distribution across the assembly room floor, where 60 technicians in white coats are steadily turning them into watches. The coats, by the way, have fine metallic strips woven through them, which are given a low magnetic charge to attract dust away from the watches. As is standard practice, the room is also kept at higher air pressure than those around it, with air blown from ceiling to floor – all to keep the dust out.

A casual glance across the room wouldn’t reveal anything particularly notable among quality watch brands – but the closer you look, the more Tudor’s dedication to marginal gains reveals itself. It follows Japanese industrial methods, such as the “5S” doctrine, which states that only the absolutely necessary tools should be used, and each has its own outlined space at every identical workstation. Every employee can switch places (signing into each desk with a fingerprint scanner) and find things exactly as they are used to. Another Japanese ideology, the “kaizen” principle of constant improvement and evolution, is embraced: little changes are made week in, week out, and a prototype workstation is up and running in one corner, ready to be rolled out across the floor.

Tudor invests heavily in aspects of production that are neither glamorous or photogenic: improvements that the customer will never feel – except, perhaps, when it keeps the price below that of its rivals. One such example is a machine commissioned especially for the painstaking process of fitting hands to a dial – a critical procedure that can require six months’ training to perfect by hand, and can be a common cause of repetitive strain injuries. Tudor has a machine that switches between different models of watches on the assembly line, a task that used to take 30 minutes and now takes 30 seconds. Or take the microphone developed to listen for the “click” as the date wheel of the movement rotates into position, or the torque winding tool for screwing in the crowns. Even the quality-control team have bespoke 3D-printed holders to work on the watches at a comfortable angle. It’s an ergonomic consultant’s dream.

Once assembled, each watch is diligently tested. First by hand, on quality-control benches at the back of the room, where one of the main tasks is removing any human bias that may have crept in along the assembly line, which is said can account for differences in perception of up to five per cent in various different companies. The cased-up watch is checked for its accuracy – Tudor regulates both its in-house and outsourced movements to a daily standard of -2/+4 seconds, a significant improvement on the COSC chronometer tests that the individual movements will already have passed.

And then there is the most important test – for the end user, at least: checking the watch’s water resistance. Up to 100 watch “heads” – cased-up watches without straps or bracelets – are stacked in trays before being lowered into a hyperbaric chamber (a dustbin-sized tank full of water 5cm-thick reinforced steel walls) where they will be subjected to pressures beyond their stated depth ratings.

Regular models, typically water-resistant to ten bar, approximately depths of 100m, are tested to a further ten per cent of stated maximum, while dive watches (those with ratings in excess of 300m, such as the 500m-rated Pelagos) are tested to a further 25 per cent. Bronze-cased watches are only sent down in batches of ten, which Tudor says reduces the time spent in the water. Even though the brand uses aluminium bronze which is far more resistant to corrosion than ordinary bronze, you don’t want the watch to begin its process of patination before it even reaches the customer.

Having submitted to these checks, each watch is dispatched to an underground chamber where it will spend three days being put through a fully automated series of tests. (It is common practice for Rolex’s buildings to extend as far underground as above; among other things, they have their own customs office down there so that watches can be exported directly from the factory without the need for border checks.)

Very few watches fail a quality control check at this point, largely because every part is tested to its limits earlier in the lifecycle of a new watch: we visit the R&D rooms where miniscule components (in this case, a single escapement pinion) are stress-tested to simulate ten years of life; crowns are pushed, pulled and turned ad infinitum, and the strength of the hands is assessed by using them to turn the movement, sending the force backwards through the watch.

Tudor also let us observe an aspect of its watches that’s very rarely seen by journalists: the process of making its straps. Normally there’s a good reason this isn’t part of the itinerary – even the top brands outsource this part, mostly from outside Switzerland, and they would be made almost entirely by machine. Tudor also outsources its straps, but they are a cut above the rest – even, we would venture so far as to say, Rolex cannot tell such an interesting story about the humble means of affixing your watch to your wrist.

When Tudor bounced back in 2010, it was decided that it could break step with Rolex and offer watches on fabric straps; this coincided with – and arguably helped to create – a wider trend of watch aficionados becoming interested in swappable straps and more casual looks. For this it turned to French textile studio Julien Faure, a family-owned firm near St Etienne, in the heart of France’s textile region. Since the renaissance, the towns around Lyon specialised in weaving ribbons and other narrow fabrics, with dozens of cottage industry businesses. Founded in 1864, Julien Faure is one of the few remaining, and as others have gone out of business over the years, it has made a point of buying up their machinery and preserving the knowledge base – it still operates jacquard looms that are over 150 years old.

That’s not to say there haven’t been modernisations along the way. Julien Faure was the first to computerise its design process in the 1980s – it couldn’t find anyone that had been sufficiently interested to develop software for jacquard looms, so hired coders and created it itself. It became the number-one software package for textile weavers around the world. A version of the original program is still used today, allowing each design to be visualised in 3D before being loaded on to the complex machines. A single ribbon can have 500 strands of yarn in the warp (running the length of the design) with four or five different wefts and as many as five layers. There are more than 150 colours of yarn in the stockroom across multiple materials. This kind of intricacy allows Julian Faure to make everything from Papal vestments to illustrated “novelty” braces. The machines have been updated, too. Alongside the wooden looms are modern equivalents, strung with neon yellow strings of Kevlar instead of cotton.

When Tudor approached in 2009 asking for a simple NATO-style fabric strap, it’s no surprise that the request was seen as somewhat simple. They considered making it in silk, but durability was an issue, and it still wasn’t sufficiently impressive. After some thought, Tudor and Julien Faure settled on the idea of weaving the NATO strap – which normally consists of layers of fabric stitched together, with the spring bars between them – in a “monobloc” construction. It would comprise one single piece of fabric with the tunnels for each bar woven into it . The result would be something slimmer than anything else on the market, with fewer seams to fray, and the positioning of the bars would be more precise, meaning the watch would be less likely to slide around on the wrist.

The end result was patented. It uses 500m of yarn per strap, passes all of Tudor’s resilience and strength tests and takes around half an hour to weave. Once woven, the straps are sent to another company for cutting, perforating and edge finishing, as well as adding the metal buckles. From there, the finished straps are shipped to Tudor in Geneva, where they, like everything else, enter The Church, ready to be summoned to the assembly floor.

This article was originally published by WIRED UK

Julian Chokkattu

Simon Lucas

Brenda Stolyar

Scott Gilbertson

Parker Hall

Nena Farrell

WIRED COUPONS

Save $7 To $23 On Turbo Tax Online

H&R Block Promo Code: Save Up To 20% On 2024 Tax Software

Enjoy $15 Off Your Orders With Instacart Coupon When You Spend $50

50% Off Your First Order Of $15+ With Code

Finish Line Coupon $15 Off $150 On Sneakers And More

Groupon Coupon: Extra 15% Off Any Size Order

- Share full article

Advertisement

Supported by

In Switzerland, Seeing Where the Watch Magic Happens

Witnessing the peace and the ‘passion’ during a tour of Roger Dubuis.

By Kathleen Beckett

GENEVA — Anyone who loves watches, collects watches or is simply interested in watches wants to do one thing: visit a place where watches are made and see one as it is being created.

That is not always so easy.

The “manufacture” — as the ateliers or factories are called in Switzerland, a.k.a. watch central — are as busy producing their wares as any workplace would be. Plus, in the highly competitive luxury watch market, there also is a sense of wanting to maintain privacy , of protecting the way companies do what they do.

While it is not common for a watch company to open its doors to the curious unless they are Very V.I.P. customers, some brands have created experiences such as guided tours and workshops that allow the public to have a look. But they are not a Disneyland for watch fans, and some require a long drive from a major city.

For example, Zenith offers reservation-only tours once a week in Le Locle, in the Jura Mountains, about 150 kilometers, or 93 miles, northeast of Geneva. In the Vallée de Joux, near the border with France, Jaeger-LeCoultre offers workshops at its Atelier d’Antoine at its headquarters in Le Sentier, as does Audemars Piguet in its Musée Atelier in Le Brassus. Vacheron Constantin and F.P. Journe also allow visits to their more Geneva-centric operations, but only to people they consider the most ardent, and acquisitive, of clients.

Another brand — Roger Dubuis, known for its high-end watches, often skeletonized and often in collaboration with luxury car brands — recently opened its doors in Meyrin, on the outskirts of Geneva, to a journalist and a photographer who were greeted by what it calls its “manufacture ambassador,” Francesca Stellino.

Her job is to welcome visitors who have been recommended by a watch boutique (she conducts tours in English, French and Italian) and show them how Roger Dubuis does what it does.

She began the tour in a hallway, in front of a poster with the company’s star-shaped logo, and talked about how the watchmaker Roger Dubuis started the brand in 1995 and championed collaborations with Pirelli tires and Lamborghini cars.

She explained that she was starting the tour there because, she warned, once we passed through a set of heavy doors onto the factory floor we might have trouble hearing her. And she was right.

The doors opened to a floor filled with dozens of big metal machines making a racket. They were being used to create components, as many as 360, that go into making a Roger Dubuis watch. Considering that the brand says it produces as many as 3,000 watches a year, that is a lot of pressing, cutting, milling, filing and polishing.At points throughout the process, parts were washed in what Ms. Stellino called, no surprise, the “washing room.” What went on inside resembled the action behind a fast-food counter, with components dropped into wire baskets and dipped into liquids, like baskets of French fries being lowered into oil.

Next step was in the “rodage et tribofinition” room, where parts were polished using a luxurious exfoliant — soap with diamond powder. Back on the main factory floor, we passed a storage cabinet that looked like a floor-to-ceiling wine rack filled with hundreds of metal rods of various widths. They were destined to be turned into pieces like “pinions, screws and wheels,” Ms. Stellino said. The three-meter-long (10-foot) metal cylinder that forms those is called the décolletage. Once the rods are cut, some of the round discs that result are run through a different machine that creates tiny teeth around their circumference that will eventually engage a watch’s gears.

Ms. Stellino stopped in front of a machine so old that some of the orange paint covering its surface had chipped away. “It’s the mother of micromechanics,” she said, used to cut “some of the crazy components of Roger Dubuis watches, like the hammers that produce the sound of the minute repeater.”

Once the pieces are produced, they head to other, quieter workrooms, and into the hands of artisans, male and female, young and mature. More polishing is in order, even on the tiniest of pieces, and it is done in one of several ways, using pastes or the most refined of sandpapers. Polishers require a “minimum of 10 years’ experience,” Ms. Stellino explained. “They work with their eyes and their ears,” listening for the particular sound that tells them that the polishing is right.

One of the workers is the company’s expert in polishing tourbillon cages until they shine like a black mirror, the “poli noir” or the black polish finish that, Ms. Stellino said, “was Mr. Dubuis’ favorite.”

Cameras zeroed in on some of the work the artisans were doing and magnified it on screens around the workrooms so visitors could see exactly what was being done.Next, we headed to the floor where the parts are assembled and turned into watches, and also where clients’ watches with complications are serviced. But first we put on white lab coats and covered our shoes with blue plastic bootees that looked like shower caps, the better to keep us from tracking in dirt and dust. Once again, we opened a set of heavy doors, but this time it was to a sanctuary of quiet concentration.