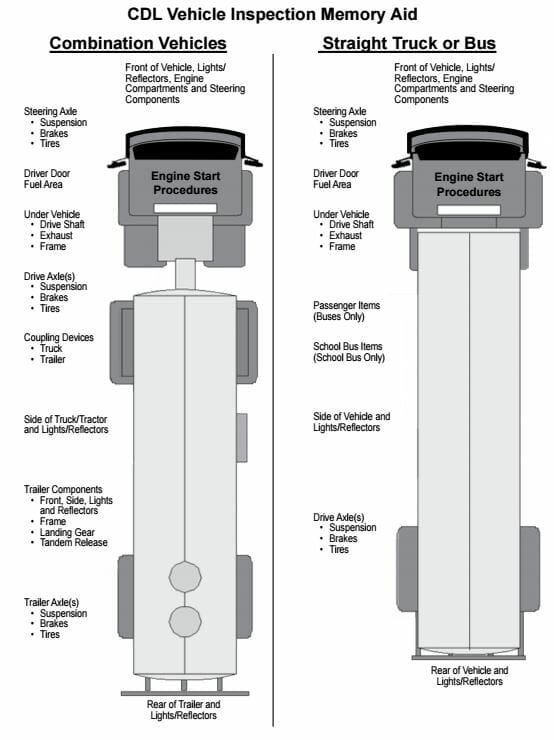

CDL Pre-Trip Inspection Checklist

Studying this Class-A CDL pre-trip inspection checklist is an important part of truck driver training. Before getting your Class-A CDL and finding an entry level truck driving job , most states will require students to pass a DOT (department of transportation) pre-trip inspection test and a general knowledge test .

Each company’s pre-trip inspection varies slightly. Most likely you will have to do the coupling system, light check and in-cab inspections plus one of the remaining three sections.

Pre Trip Inspection Checklist

Download free and print it! Printable Pre Trip Inspection Checklist (PDF)

There are many sections to learn but the test is not as difficult as it may seem. Studying our simplified Class-A pre-trip inspection checklist and taking classes at your local CDL training school will get you prepared.

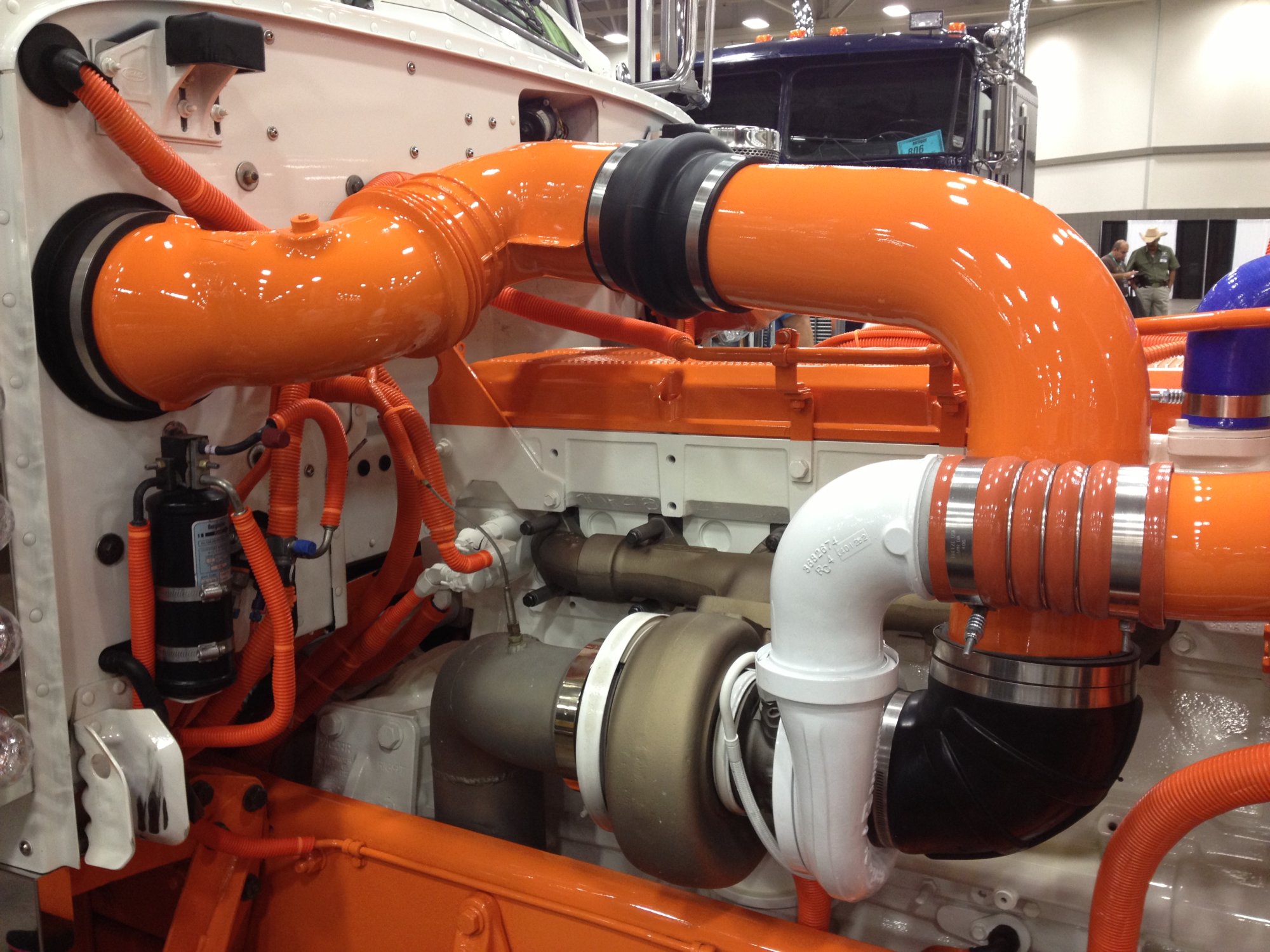

Engine Compartment

Driver door fuel area, coupling area, light check, in-cab inspection and brake tests, belt driven alternator, belt driven water pump, brake chamber, brake lining, caste nuts and cotter pins, coolant reservoir, gear box and hoses, gear driven air compressor, gear driven power steering pump.

- General Hoses

Leaf Springs

Power steering fluid reservoir, shock absorber, slack adjuster and push rod, spring hanger, steering column, what to check for:.

When checking the engine compartment, you will always want to make sure the following components are properly mounted and secured. You should also make sure they are not cracked, bent or broken. The items you will need to check for include:

- Make sure all of the wires are connected. The belt should not be cracked or frayed and the free play on the belt should be between ½ to ¾ of an inch.

- The free play on the belt should be between ½ to ¾ of an inch. Also check all the hoses running to and from the water pump to make sure nothing is leaking.

- The brake chamber should not be leaking air.

- The brake drum should be properly mounted and secure.

- The brake hose is rubber, so it is important to make sure it is not leaking air.

- Check for oil or debris on the lining. There should be at least ¼ of an inch of friction material.

- Make sure all three caste nuts and cotter pins are present.

- The reservoir should not leaking and must be filled to the manufacturer’s specifications.

- Make sure the drag link is properly mounted and secure, and not cracked, bent or broken.

- The gear box and hoses should have no abrasions, bulges or cuts, and should not be leaking.

- Although the air compressor is hard to see, you must make sure it is properly mounted and does not leak.

- The steering pump is located in the same place as the air compressor and is also gear driven. Ensure the steering pump is not leaking.

General Hoses (Passenger and Driver’s Side)

- The hoses should be secure at both ends. There should be no abrasions, bulges or cuts. Fluids run through these hoses, so it is important to make sure they are not leaking.

- The hub seal (or axle seal) should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure none of the leaf springs have shifted.

- Check for leaks under the truck.

- There should be no lug nuts missing. Look for rust trails, powder residue and cracks around the bolt holes.

- The oil level should be filled to the manufacturer’s specifications.

- Make sure the pitman arm is properly mounted and secure. It should be not cracked, bent or broken.

- Make sure this reservoir is not leaking and filled to the manufacturer’s specifications.

- The rim cannot have any unauthorized welds.

- Make sure the shock absorber is not leaking. If it is leaking, the leak will be at the point where the top and bottom portion of the shock meet.

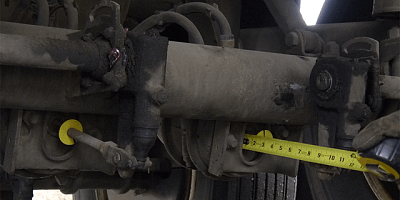

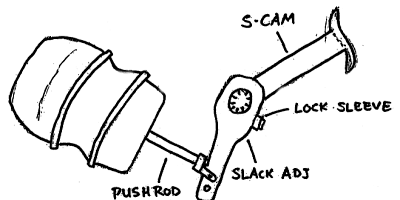

- With the brakes released and pulled by hand, the push rod should never move more than one inch.

- The spring hanger should be properly mounted and secure.

- Make sure the steering column is properly mounted and secure. It should not be cracked, bent or broken.

- Look for abrasions, bulges or cuts on the tread or sidewalls. Tread depth should have a depth no less than 4/32 of an inch. Tires must be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- Make sure the tie rod is properly mounted and secure, not cracked, bent or broken.

- Make sure all are accounted for.

Back to top of Engine Compartment

Catwalk and Steps

Door and hinges, drive shaft, exhaust system, frame and cross members, spring mount.

Again it is important to make sure these items are properly mounted and secure. Look for cracks, bends, and breaks.

- The actual airbag is rubber, so it is important to check for abrasions, bulges, cuts and leaks, in addition to any missing mounting bolts.

- The axle seal should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure to mention the brake chamber is not leaking air.

- Make sure the brake drum is secured properly. Also look for cracks, bends and breaks.

- Check the brake hose at both ends to make sure it is not leaking air.

- There should be no oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- The cat walk and steps should be clear of any loose objects.

- Physically demonstrate that the doors open, close and latch properly. Door seals should not be worn, torn or rotten.

- The drive shaft should not be twisted and the u-joints should be free of any debris.

- The tread and sidewalls should have no abrasions, bulges or cuts. The tread depth should be no less than 2/32 of an inch. Tires should be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- The exhaust system should show no signs of leaks.

- There should be no unauthorized holes or welds. Bundle up the cross members to ensure none are missing.

- Fuel should not be leaking from the tank and the cap should always be on tight.

- Rust trails could indicate loose bolts, while powder residue and racks around the bolts could mean the bolts have been over-tightened.

- Mirrors should be clean for best visibility.

- Make sure the mud flap is secured properly. Also look for cracks, bends and breaks.

- Make sure to mention there should be never be any unauthorized welds.

- The shock absorber should be secure at both ends and not leaking. If it does leak, it will leak in the middle.

- With the brakes released and pulled by hand, the push rod should not move more than one inch.

- If you are equipped with duals, check to see there is proper spacing between the tires and there is nothing stuck.

- The spring arm should be secure at both ends.

- The spring mount should be secure at both ends.

- Make sure the torque arm is secured properly. Also look for cracks, bends and breaks.

- Make sure to check and mention that no U-bolts are missing.

Back to top of Driver Door Fuel Area

Electric Line

Locking jaws, mounting bolts, release arm, sliding fifth wheel locking pin.

- Air lines should be secure at both ends with no abrasions, bulges or cuts. They should not be leaking, dragging or tangled.

- Make sure the apron is properly mounted and secure. Look for cracks, bends and breaks.

- Make sure there is enough space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

- The electric line should be secure at both ends. There should be no abrasions, bulges, cuts or exposed wires.

- The gap is not an actual item, however there should be no space between the apron and the skid plate.

- The seals should be in good condition with no cracks, signs of rotting, or leaking air.

- Make sure the king pin is properly mounted and secure. Look for cracks, bends and breaks.

- You must physically check that the locking jaws is fully locked around the king pin.

- No mounting bolts should be missing.

- Make sure the platform is properly mounted and secure. Look for cracks, bends and breaks.

- The release arm should be in the fully locked position.

- The skid plate needs to be properly lubed.

- The pin must be in the fully locked position.

Back to top of Coupling Area

Header Board

Landing gear, rear door and hinges.

- Shock Absorbers

Tandem Frame and Release

Trailer tire.

- Again make sure the airbag has no abrasions, bulges, cuts or leakings. The airbag should not be missing any mounting bolts.

- The brake chamber should be properly mounted so that is does not leak air.

- The brake hose should be secure at both ends with no abrasions, bulges, cuts or leaks.

- Check for oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- There cannot be any missing cross members.

- The header board cannot have any holes or missing rivets.

- The landing gear must be fully raised and the cradle handle secure.

- Rust trails indicate loose bolts. Powder residue and cracks around the bolt holes could be an indication of over-tightened bolts.

- The rims cannot have any unauthorized welds.

- The rear door should open, close and latch properly. Door seals should not be worn, torn or dry rotten.

- The shock absorber should be checked at both ends for leaks.

- When the brakes are released and pulled by hand, the push rod should not move more than one inch.

- Release handle and locking pins should be in the fully locked position.

There should be no abrasions, bulges or cuts to the tread or sidewalls. Tread depth should be no less than 2/32 of an inch. The tire should be properly filled to manufacturer’s specifications and checked with an air gauge.

- Front of the truck

- Both sides of the truck

- Rear of the truck

- Both sides of the trailer

- Rear of the trailer

Back to top of Trailer

The five functions are:

- Left turn signal

- Right turn signal

- Four way flashers

- High/low beams

- Brake lights

Back to top of Light Check

- Airbrake Test

Air Pressure Gauges

Emergency equipment, heater and defroster, lighting indicators, oil pressure gauge, parking brake, service brake check, water temperature gauge, windshield and mirrors, windshield wipers and washers.

The last section is In-Cab Inspection and Brake Tests. For the In-Cab Inspection you will once again want to make sure all of the following components are properly mounted and secure. As well as the following:

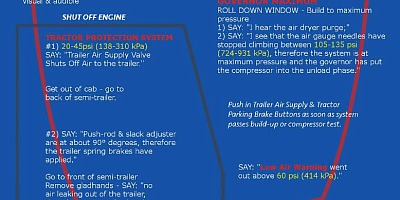

Air Brake Test

There are three stages to an air brake test:

- Applied Pressure Test – When doing the Applied Pressure Test, you will want to build the air pressure to governor cut out. Put the truck in the lowest gear, turn the engine off and immediately turn it back on. Push in the tractor and trailer valves which will then release the parking brakes. Push and hold the brake pedal, allowing the gauges to stabilize. When the gauges have stabilized, announce the Primary and Secondary PSI. Listen for air leaks while doing this.

- Warning Light and Buzzer – Pump down on the brake pedal until the warning light and buzzer comes on. This is typically at or before 60 PSI.

- Tractor/Trailer Protection Valve Pop Out – Pump down on the brake pedal until the tractor and trailer protection valves pop out, this will be between 20 and 40 PSI.

- The air pressure gauges should build to governor cut out.

- Your truck should have a fire extinguisher, three red reflective triangles and spare electrical fuses.

- Demonstrate both the heater and defroster are working properly.

Horns (Air Horn and City Horn)

- Blow both horns to make sure they are working.

- Check the left turn, right turn, four way flashers and high beams; also point these out on the dashboard.

- Make sure transmission is in neutral and then fully depress the clutch. Turn the key on, check the ABS light, announce when it comes on and off, and start the engine.

- The seat belt should not be ripped or frayed and should adjust and latch properly.

- The engine oil pressure gauge should rise to normal operating range.

- Trailer Parking Brakes – Set the trailer brake, release the tractor brake, then tug lightly on the trailer.

- Tractor Parking Brakes – Set the tractor brake, release the trailer brake and tug lightly on the trailer.

- Release both the tractor and trailer brakes. Drive at idle speed. Apply the service brake to make sure you come to a complete stop and that it doesn’t pull to the left or right when applying the brakes.

- The voltmeter should be charging between 13 and 14 volts.

- The water temperature gauge should also rise to normal operating range.

- The windshield and mirrors must be clean, with no obstructions and in proper adjustment.

- Demonstrate the wipers and washers are working properly by spraying the windshield.

Back to top of In-Cab Inspection and Brake Tests

During a CDL pre-trip inspection, truckers inspect many aspects of their commercial vehicle, including the overall safety of the vehicle; major hoses, fluid levels, and vehicle belts; the clutch or gear shift; and emergency equipment. The driver demonstrates their knowledge by walking around the vehicle, checking various safety components and explaining why each part should be checked for safety.

Reference and practice tests:

- Printable Pre Trip Inspection Checklist (PDF)

- CDL General Knowledge Practice Test

- Pre Trip Inspection Practice Test

- CDL HAZMAT Endorsement Practice Test

Edited for 2024 on 12/5/23

Trucker's Blog | A Complete Trucking Guide

- Privacy Policy

- Trucker Store

- Write for us

7 step air brake test

Scroll Down to download 7 Step Air Brake Test Cheat Sheet pdf

What is the 7 Step Air Brake Test?

A commercial driver must perform a pre-trip inspection before taking a truck trailer on any public road. The most important part of the pre-trip inspection is the 7 step air brake test.

Please note that this article is not an actual air brake test, this is just for practice.

Always do the 7 step air brake test in order. Initially, it is difficult to memorize the 7 steps air brake test, but the word “LAGASS” makes it easier to remember the steps in the 7 step air brake test. The abbribation ofpsi “LAGGASS” is

- L for Low Air Warning Device.

- A for Air Pressure Buildup.

- G for Governor Cut Out.

- G for Governor Cut In.

- A for Air Loss Rate.

- S for Spring Brake Test.

- S for Service Brake Test.

Tractor Trailer Pre-Trip Inspection

How to do a 7 step air brake test?

Before starting the air brake test, park the vehicle on a flat surface, apply spring brakes and wheel chokes. Start testing with the low air warning device.

1. The low air warning device test

There is an indicator on the vehicle’s dashboard that warns the driver when the air pressure drops below the required level. This device can be an audible warning, an indicator or both.

How to test the low air warning device?

- Make sure the air pressure is above 90psi.

- Turn the imagination switch on or keep the engine running.

- Pump down the brake pedal and keep an eye on the dashboard(where the visible indications appears, mostly on the dashboard, in some vehicles in the gauges) and air pressure gauges.

- A visible and or audible signal must activate on or before 55psi.

If the low air warning device does not activate, it is a major defect.

2. The air pressure build-up test.

This test evaluates the working of the air compressor. When travelling on the road, the air pressure drops with the frequent use of brakes. But, the air compressor keeps filling up the air tanks as per instructions from the governor to meet the required air pressure. The compressor must fill the required air within a time constraint, called air pressure build-up. Air pressure build-up depends on your province, in Ontario it is 85psi – 100psi in 2 minutes engine running in between 600 to 900 rpm.

How to test air pressure buildup?

- Make sure the engine is running in between 600rpm to 900rpm.

- Pump down the brake paddle and lower the air pressure to 85psi.

- Now keep watching the needles in the air pressure monitoring gauges.

- The needles must start moving and go from 85psi to 100psi within 2 minutes. The air pressure must build up from 85psi to 100psi within 2 minutes.

3. Governor cut-out test

What is the governor’s cut-out test.

When the required air pressure in the air brake system is reached, the governor shuts off the air compressor, this is called a governor cut out. We hear a “thesis.” sound when the governor cuts out. This noise comes from the governor cut out and the discharge from the air dryer. The minimum governor cut-out is 100psi, and the maximum is 145psi.

Note down the governor’s cut-out reading.

How to test the governor cut-out?

- Keep the engine running from 600 to 900rpm.

- Watch the needles moving and open the driver’s window.

- Listen to the (“thisssss”) sound. This is the governor cut-out.

- The minimum governor cut-out is 100psi, and the maximum is 145psi.

Why is the governor’s cut-out test important?

If the governor does not cut, the air pressure in the brake system will continue increasing, which can damage the brake system. But if the governor fails and the air pressure continues to rise,the safety valve(on air tanks) opens up at 150psi and saves the air brake system.

4. Governor cut-in test

What is the governor cut-in test.

The moment the compressor throws air into air, tanks are called governor cut in. The governor must cut in at 20psi to 25psi below the governor cut-out. The governor cut-in and the cut-out is the normal operating range(NOR) of an air brake system.

How to test the governor cut in?

- Pump down the brake paddle and lower the air pressure 20psi to 25psi from the cut-out reading.

- Now, look at the air pressure monitoring gauges. The governor is cutting in if the needles move, which means the air compressor started throwing air into the air tanks.

- If the needles do not start moving, pump down the peddle again and lower the air pressure by 5psi and watch the needles again.

- Repeat the above until the air pressure reaches 80psi.

The minimum governor cut in is 80psi. Means governor must cut in at 80psi.

5. Air loss rate test.

What is the air loss rate test.

The air loss rate test is a measurement of air leakage from the air brake system.

How to test the air loss rate?

- Make sure the vehicle is on the level surface and the air pressure is within the normal operating range(cut-out and cut-in).

- Apply the wheel chocks.

- Turn the engine off.

- Release the spring brakes.

- Apply and hold the service brakes for a minute.

- Open the window and listen for the air leaks.

- The air brake system in a tractor-trailer must not lose more than 4psi in a minute after an initial loss.

The air loss rate limits are 3psi (straight truck, bus), 4psi (tractor-trailer) and 6psi (tractor and two trailers) in a minute.

6. Service brake test.

What is a service brake test.

The service brake test is a test of a vehicle’s stopping ability. Your brake paddle is a service brake. Check the brake peddle for rust, debris and the cleanness of the area. The debris under the brake paddle, loose objects on the floor can create dangerous situations.

How to check the service brakes?

- Apply the spring breaks.

- Remove the wheel chocks.

- Now release the spring brakes and put the vehicle in drive.

- Let the vehicle roll and apply the service brakes.

The service brakes must hold the vehicle in parallel.

7. Spring brake test

What is the spring brake test.

The spring brakes test is the test of the parking brakes. There is a push/pull yellow knob on the dashboard for the tractor parking brakes.

How to test the spring brakes?

- Put the vehicle into the transmission and let it roll for a yard.

- Apply the spring brakes pulling the yellow knob.

The spring brakes must hold the vehicle in parallel and smooth.

Why is the spring brake test important?

Spring brakes are parking brakes. If they are not working, we won’t be able to park the vehicle.

The next steps in air brake testing are… 1. Draining the air tanks. 2. Pushrod measurement. You can find both steps in the link below.

How to adjust air brakes

Download in cab 7 step air brake test pdf here

CDL 7 Step Air Brake Test video (please read the air pressure buildup time 2 mins in the video)

Trucking in Canada

7 step air brake test pdf air brakes practice test pdf Air Loss Rate Air Pressure Buildup cdl air brake test cheat sheet cdl air brake test pdf cdl air brake test pre trip cdl air brake test video cdl air brakes study guide Governor Cut Out how to do air brake test on tractor trailer how to pass the air brakes test in cab air brake test Low Air Warning Device Service Brake Test Spring Brake Test

3 Leave a Reply

This resource outlines a structured approach to conducting an air brake test, which could be valuable for drivers or technicians responsible for ensuring the proper functioning of air brake systems. Are there any common pitfalls or mistakes?

[…] 7-step-air-brake-test […]

Never see this message again.

- Free Practice Tests

Commercial Driving

- Introduction

Getting a CDL

- Fees and costs

CDL Types & Permits

Endorsements & Restrictions

CDL Exam Preparation

Written exams

- General Knowledge

- Combination

- Doubles/Triples

Practical exams

- TSA background check

- Retake policy

CDL Maintenance

ELDT Training & Certification

CDL how-to guides

Free Air Brakes CDL Test Practice: Questions & Tips for Aspiring Commercial Drivers

Get ready to ace the CDL Air Brake Test with our free questions. Understand every aspect of air brake systems and test requirements to ensure safety and compliance on the road.

Written by Andrei Zakhareuski. With over 16 years of expertise, Andrei leads Driving-Tests.org, a top online resource for driver education. His leadership has established vital partnerships with over 2,600 libraries, educational bodies, and state agencies.

In a hurry? Jump to a free Air Brakes practice test:

- Alabama - AL - Alabama Air Brakes Practice Test

- Alaska - AK - Alaska Air Brakes Practice Test

- Arizona - AZ - Arizona Air Brakes Practice Test

- Arkansas - AR - Arkansas Air Brakes Practice Test

- California - CA - California Air Brakes Practice Test

- Colorado - CO - Colorado Air Brakes Practice Test

- Connecticut - CT - Connecticut Air Brakes Practice Test

- Delaware - DE - Delaware Air Brakes Practice Test

- District of Columbia - DC - District of Columbia Air Brakes Practice Test

- Florida - FL - Florida Air Brakes Practice Test

- Georgia - GA - Georgia Air Brakes Practice Test

- Hawaii - HI - Hawaii Air Brakes Practice Test

- Idaho - ID - Idaho Air Brakes Practice Test

- Illinois - IL - Illinois Air Brakes Practice Test

- Indiana - IN - Indiana Air Brakes Practice Test

- Iowa - IA - Iowa Air Brakes Practice Test

- Kansas - KS - Kansas Air Brakes Practice Test

- Kentucky - KY - Kentucky Air Brakes Practice Test

- Louisiana - LA - Louisiana Air Brakes Practice Test

- Maine - ME - Maine Air Brakes Practice Test

- Maryland - MD - Maryland Air Brakes Practice Test

- Massachusetts - MA - Massachusetts Air Brakes Practice Test

- Michigan - MI - Michigan Air Brakes Practice Test

- Minnesota - MN - Minnesota Air Brakes Practice Test

- Mississippi - MS - Mississippi Air Brakes Practice Test

- Missouri - MO - Missouri Air Brakes Practice Test

- Montana - MT - Montana Air Brakes Practice Test

- Nebraska - NE - Nebraska Air Brakes Practice Test

- Nevada - NV - Nevada Air Brakes Practice Test

- New Hampshire - NH - New Hampshire Air Brakes Practice Test

- New Jersey - NJ - New Jersey Air Brakes Practice Test

- New Mexico - NM - New Mexico Air Brakes Practice Test

- New York - NY - New York Air Brakes Practice Test

- North Carolina - NC - North Carolina Air Brakes Practice Test

- North Dakota - ND - North Dakota Air Brakes Practice Test

- Ohio - OH - Ohio Air Brakes Practice Test

- Oklahoma - OK - Oklahoma Air Brakes Practice Test

- Oregon - OR - Oregon Air Brakes Practice Test

- Pennsylvania - PA - Pennsylvania Air Brakes Practice Test

- Rhode Island - RI - Rhode Island Air Brakes Practice Test

- South Carolina - SC - South Carolina Air Brakes Practice Test

- South Dakota - SD - South Dakota Air Brakes Practice Test

- Tennessee - TN - Tennessee Air Brakes Practice Test

- Texas - TX - Texas Air Brakes Practice Test

- Utah - UT - Utah Air Brakes Practice Test

- Vermont - VT - Vermont Air Brakes Practice Test

- Virginia - VA - Virginia Air Brakes Practice Test

- Washington - WA - Washington Air Brakes Practice Test

- West Virginia - WV - West Virginia Air Brakes Practice Test

- Wisconsin - WI - Wisconsin Air Brakes Practice Test

- Wyoming - WY - Wyoming Air Brakes Practice Test

CDL Air Brakes Test Overview

- Written Exam

- Practical Exam

- Test Requirements

The written part of the Air Brakes CDL Test focuses on assessing your knowledge of air brake systems, including system components, operation, and safety protocols.

Preparing for the CDL Air Brake Test

Study the Components

Begin with learning about air brake system components and their functionality. Knowing each part’s role is crucial for understanding the entire system.

Practical Experience

Gain hands-on experience with air brake systems, if possible. This could include training courses or practicing with a qualified instructor.

Practice Tests

Utilize free Air Brake practice tests for assessing your readiness and familiarizing yourself with the test format.

Pre-Trip Inspection Practice

Practicing performing a pre-trip inspection is essential, as this is a critical part of the practical exam and daily operation of air brake systems.

Exam Details and Requirements

key components of the air brake system.

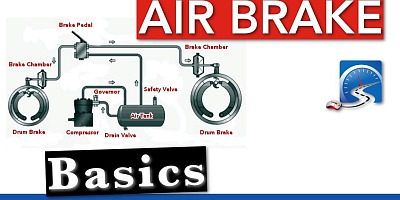

Understanding Air Brake Systems

Air brake systems, essential for commercial vehicles, consist of several components. Key parts include the compressor, reservoirs, valves, and brake chambers, each playing a crucial role in the system’s functionality.

Functionality of Air Brakes

When the brake pedal is pressed, air from the compressor travels to the brake chambers. This air pressure clamps the brake pads onto the brake drum, slowing or stopping the vehicle.

Frequently Asked Questions about the CDL Air Brake Test

How to Pass the Test on the First Attempt

To pass the CDL air brakes test the first time, focus on a blend of theoretical knowledge and practical application, including hands-on practice and thorough study of air brake systems.

Validity and Maintenance of Air Brake Endorsement

The air brake endorsement is valid as long as your commercial driver’s license is valid. However, a knowledge test or a refresher course on air brakes every two years is recommended to maintain your endorsement.

Retaking the Test After Failure

If you fail the test, you can retake it after a state-specified waiting period. You may need to pay a retake fee and complete additional training or education.

What is the CDL Air Brake Test?

The CDL Air Brake Test is a specialized segment of the CDL exam focused on a driver’s understanding of the mechanics, operation, and safety protocols associated with air brake systems in commercial vehicles.

The Importance of Air Brake Knowledge

Mastery of air brakes is not just about passing a test – it’s crucial for the safety of the driver and everyone on the road. The air brake system is complex and requires thorough understanding to operate correctly.

Key Topics Covered

Expect to be tested on air brake system parts, inspection protocols, proper usage, and emergency response.

Passing Criteria

You will need a score of 80% or higher to pass, which translates to correctly answering at least 20 out of 25 questions.

Pro Tip : During the test, take your time with each question and remember the practical applications of what you’ve studied. Theory when backed by practical understanding is a winning combo for the CDL Air Brake Test.

Sample Air Brake Written Exam Questions

To give you a taste of what to expect in the actual CDL Air Brake Test, here are some sample questions. Use these to gauge your understanding and practice answering.

Question 1: Air Brake System Pressure

At what psi does the air compressor governor typically cut-in to maintain air pressure?

- Correct Answer: A) 100 psi

Question 2: Brake Lag

How much lag time is there in an air brake system?

- A) Less than one second

- B) Between 2-3 seconds

- C) Up to half a second

- Correct Answer: C) Up to half a second

Question 3: Air Tank Draining

Why is it important to drain water from compressed air tanks?

- A) To prevent air pressure from becoming too high

- B) To prevent freezing in cold weather

- C) To improve fuel efficiency

- Correct Answer: B) To prevent freezing in cold weather

Question 4: Brake Fading

What causes brake fading or failure?

- A) Overheating due to excessive use

- B) Cold weather conditions

- C) Improper brake fluid level

- Correct Answer: A) Overheating due to excessive use

Question 5: Spring Brakes

When do spring brakes usually activate?

- A) When air pressure falls below 45 psi

- B) When air pressure rises above 60 psi

- C) When air pressure falls below 20 psi

- Correct Answer: A) When air pressure falls below 45 psi

Remember, these questions are just samples. For more comprehensive preparation, utilize the full suite of practice questions available at Driving-Tests.org .

The key to success is a blend of comprehensive study, practical understanding, and a calm approach to the test. Utilize all available resources and take the time to fully grasp the intricacies of air brake systems.

After the Test

Once you’ve passed the test, you’ll be equipped to drive vehicles with air brakes, a skill that expands your employability and opportunities within the commercial driving industry.

Ready to start preparing? Visit Driving-Tests.org for comprehensive study guides and free practice tests to ensure you’re ready to ace your CDL Air Brake Test.

Secure your CDL with confidence!

Our exclusive CDL Premium program offers comprehensive online training with an ELDT certificate, authentic exam questions, and a solid Pass Guarantee, starting at only $49. Ideal for first-time applicants, seasoned drivers, and those new to the U.S. road rules.

Explore CDL Premium

Was this page helpful?

- In a hurry? Jump to a free Air Brakes practice test:

- CDL Air Brakes Test Overview

- Preparing for the CDL Air Brake Test

- Exam Details and Requirements

- Key Components of the Air Brake System

- Frequently Asked Questions about the CDL Air Brake Test

- Sample Air Brake Written Exam Questions

- After the Test

- All Companies

- Driver Training

- All Freight Types

- Lease/Purchase

- Message Board

- Truck Driver Salary

- How to Become A Truck Driver

- Will I Be Successful?

- Truck Driving Schools

- CDL Practice Tests

- Get Your CDL

- Get Your First Truck Driving Job

- Your First 100,000 Miles

- Advanced Tips

- Sign Up Here

Select Location x

Please tell us your location.

Location not set

The Complete Pre-Trip Inspection Checklist

Due to heavy memorization, the pre-trip inspection is one of the hardest aspects of the CDL test. Also called the “Vehicle Inspection Test,” the pre-trip is one of the tests that trucking students fail the most.

With this pre-trip inspection checklist, we tell you everything you need to know and what you need to check for.

Engine Compartment – What to Check For:

When checking the engine compartment, you always want to make sure the following components are properly mounted and secured. You should also make sure they are not cracked, bent, or broken. The items you need to check for include:

Belt-Driven Alternator

All of the wires are connected. The belt is not cracked or frayed, and the free play on the belt is between ½ to ¾ of an inch.

Belt-Driven Water Pump

The free play on the belt is between ½ to ¾ of an inch, and all the hoses running to and from the water pump are tightly clamped. Ensure nothing is leaking.

Brake Chamber

The brake chamber is not leaking air.

The brake drum is properly mounted and secure.

The brake hose is rubber; it is not cracked and is not leaking air.

Brake Lining

Check for oil or debris on the lining. There should be at least ¼ of an inch of friction material.

Caste Nuts and Cotter Pins

All three caste nuts and cotter pins are present.

Coolant Reservoir

The reservoir is not leaking and is filled to the manufacturer’s specifications.

The drag link is properly mounted and secure, and not cracked, bent or broken.

Gear Box and Hoses

The gear box and hoses have no abrasions, bulges or cuts, and are not leaking.

Gear-Driven Air Compressor

The air compressor is properly mounted and does not leak.

Gear-Driven Power Steering Pump

The steering pump is properly mounted and not leaking.

General Hoses (Passenger and Driver’s Side)

The hoses are secure at both ends and are not leaking. There are no abrasions, bulges, or cuts.

The hub seal (or axle seal) is leaking and is filled to the manufacturer’s specifications.

Leaf Springs

None of the leaf springs have shifted or are bent or broken.

There are no signs of leaks under the truck.

There are no lug nuts missing. There are no rust trails, powder residue, or cracks around the bolt holes.

The oil level is filled to the manufacturer’s specifications.

The pitman arm is properly mounted and secure. It is not cracked, bent, or broken.

Power Steering Fluid Reservoir

The power steering reservoir is not leaking and is filled to the manufacturer’s specifications.

The rim does not have any unauthorized welds.

Shock Absorber

The shock absorber is not leaking. If it is leaking, the leak will be at the point where the top and bottom portion of the shock meet.

Slack Adjuster and Push Rod

With the brakes released and pulled by hand, the push rod does not move more than one inch.

Spring Hanger

The spring hanger is properly mounted and secure.

Steering Column

The steering column is properly mounted and secure. It is not cracked, bent, or broken.

There are no abrasions, bulges, or cuts on the tread or sidewalls. Tread depth should have a depth no less than 4/32 of an inch. Tires are properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

The tie rod is properly mounted and secure, not cracked, bent, or broken.

Make sure all are accounted for.

Driver Door Fuel Area-What to Check For:

Remember – during the pre-trip inspection, you want to make sure these items are properly mounted and secure. Look for cracks, bends, and breaks.

The actual airbag has no abrasions, bulges, cuts, or leaks. The airbag is not missing mounting bolts.

The axle seal is not leaking and is filled to the manufacturer’s specifications.

The brake drum is secured properly and has no cracks, bends or breaks.

Check the brake hose at both ends to make sure it is not leaking air.

There is no oil or debris on the brake lining. There is at least ¼ of an inch of friction material.

Catwalk and Steps

The cat walk and steps are clear of any loose objects.

Door and Hinges

The doors open, close, and latch properly. Door seals should not be worn, torn, or rotten.

Drive Shaft

The drive shaft is not twisted, and the u-joints are free of any debris.

The tread and sidewalls have no abrasions, bulges, or cuts. The tread depth is no less than 2/32 of an inch. Tires are properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

Exhaust System

The exhaust system shows no signs of leaks.

Frame and Cross Members

There are no unauthorized holes or welds. Bundle up the cross members to ensure none are missing.

Fuel is not leaking from the tank, and the cap is on tight.

There are no rust trails, loose bolts, powder residue, or cracks around the bolts.

Mirrors are clean, with no cracks or chips.

The mud flap is secured properly, with no cracks, bends and breaks.

There are no unauthorized welds.

The shock absorber is secure at both ends and not leaking. If it does leak, it is preferable to leak in the middle.

There is proper spacing between the tires and there is nothing stuck.

The spring arm is secure at both ends.

Spring Mount

The spring mount is secure at both ends.

The torque arm is secured properly, with no cracks, bends or breaks.

No u-bolts are missing.

Coupling Area-What to Check For:

Air lines should be secure at both ends with no abrasions, bulges, or cuts. They should not be leaking, dragging, or tangled.

Make sure the apron is properly mounted and secure. Look for cracks, bends, and breaks.

Make sure there is enough space between the tractor mud flap and the trailer landing gear, so that they don’t hit each other when making a turn.

Electric Line

The electric lines are secure at both ends. There are no abrasions, bulges, cuts, or exposed wires.

There is no space between the apron and the skid plate.

The seals are in good condition with no cracks, signs of rotting, or leaking air.

The king pin is properly mounted and secure, without cracks, bends and breaks.

Locking Jaws

Physically check that the locking jaws are fully locked around the king pin.

Mounting Bolts

No mounting bolts are missing.

The platform is properly mounted and secure, without cracks, bends and breaks.

Release Arm

The release arm is in the fully locked position.

The skid plate is properly lubed.

Sliding Fifth Wheel Locking Pin

The pin is in the fully locked position.

Trailer- What to Check For :

The airbag has no abrasions, bulges, cuts or leaks, not missing any mounting bolts.

The brake chamber is properly mounted and does not leak air.

The brake hose is secure at both ends with no abrasions, bulges, cuts, or leaks.

No oil or debris on the brake lining and at least ¼ of an inch of friction material.

No missing cross members.

Header Board

The header board does not have any holes or missing rivets.

Landing Gear

The landing gear is fully raised and the cradle handle secure.

No rust trails, powder residue, or cracks around the bolt holes.

The rims do not have any unauthorized welds.

Rear Door and Hinges

The rear door opens, closes, and latches properly. Door seals are not worn, torn, or dry rotten.

The shock absorber is secure at both ends with no leaks.

When the brakes are released and pulled by hand, the push rod does not move more than one inch.

Tandem Frame and Release

Release handle and locking pins are in the fully locked position.

Trailer Tire

There are no abrasions, bulges, or cuts to the tread or sidewalls. Tread depth is no less than 2/32 of an inch. The tire is properly filled to manufacturer’s specifications and checked with an air gauge.

Light Check

There are five locations where you must check your lights. These include:

- Front of the truck

- Both sides of the truck

- Rear of the truck

- Both sides of the trailer

- Rear of the trailer

The five functions are:

- Left turn signal

- Right turn signal

- Four way flashers

- High/low beams

- Brake lights

Inspection and Brake Tests-What to Check For: In-Cab

The last section is In-Cab Inspection and Brake Tests. For the In-Cab Inspection you once again want to make sure all of the following components are properly mounted and secure. As well as the following:

Air Brake Test

There are three stages to an air brake test:

- Applied Pressure Test – When doing the Applied Pressure Test, you want to build the air pressure to governor cut out. Put the truck in the lowest gear, turn the engine off and immediately turn it back on. Push in the tractor and trailer valves which then release the parking brakes. Push and hold the brake pedal, allowing the gauges to stabilize. When the gauges have stabilized, announce the Primary and Secondary PSI. Listen for air leaks while doing this.

- Warning Light and Buzzer – Pump down on the brake pedal until the warning light and buzzer comes on. This is typically at or before 60 PSI.

- Tractor/Trailer Protection Valve Pop Out – Pump down on the brake pedal until the tractor and trailer protection valves pop out, this will be between 20 and 40 PSI.

Air Pressure Gauges

The air pressure gauges build to governor cut out.

Emergency Equipment

Truck has a fire extinguisher, three red reflective triangles, and spare electrical fuses.

Heater and Defroster

Demonstrate both the heater and defroster are working properly.

Horns (Air Horn and City Horn)

Blow both horns to make sure they are working.

Lighting Indicators

Check the left turn, right turn, four way flashers and high beams; also point these out on the dashboard.

With the transmission in neutral, fully depress the clutch. Turn the key on, check the ABS light, announce when it comes on and off, and start the engine.

The seat belt is not ripped or frayed and adjusts and latches properly.

Oil Pressure Gauge

The engine oil pressure gauge should rise to normal operating range.

Parking Brake

- Trailer Parking Brakes – Set the trailer brake, release the tractor brake, and tug lightly on the trailer.

- Tractor Parking Brakes – Set the tractor brake, release the trailer brake, and tug lightly on the trailer.

Service Brake Check

Release both the tractor and trailer brakes. Drive at idle speed. Apply the service brake to make sure you come to a complete stop and that it doesn’t pull to the left or right when applying the brakes.

The voltmeter is charging between 13 and 14 volts.

Water Temperature Gauge

The water temperature gauge rises to normal operating range.

Windshield and Mirrors

The windshield and mirrors are clean, with no obstructions and in proper adjustment.

Windshield Wipers and Washers

Demonstrate the wipers and washers are working properly by spraying the windshield.

This is a really nice complete list, very useful.

Comments are closed.

Contact ClassADrivers.com

Please use the form below to contact our customer service or sales team.

You can also reach us at (888) 830-2326. Our normal business hours are Monday-Friday 8 a.m. to 5 p.m. (Pacific Time).

Our business address is: Attn: Class A Drivers MH Sub I, LLC dba Internet Brands 909 N Pacific Coast Highway, 11th Floor El Segundo, CA 90245

By clicking the ["Send"] button, you agree to our Terms of Use and Privacy Policy , and to the use of cookies described therein, and you also consent to the collection, storage, and processing of your data in the United States where the level of data protection may be different from that in your country.

CDL Pre-Trip Inspection Test and How To Memorize It

The pre-trip is one of the things that students fear the most and fail the most. Let’s face it, the pre-trip is intimidating because there is so much stuff to memorize. The key to learning the pre-trip inspection is preparation, memorization, and repetition. Don’t go away, in this article I have exactly what you need to make sure you pass it the first time.

It is going to take time for you to memorize everything and the only way to do this is by repeating it over and over.

Hopefully, the school where you are being trained is giving you enough time to practice it everyday you are there.

I can’t stress that enough, regardless of which method you use below you need to repeat it daily and practice on your own.

Don’t expect that your run through once a day with your instructor is enough, it isn’t.

In this article I’m going to give you 8 tips that will help you memorize the pre-trip so you are able to pass it your first time and move on with your driving career.

1. REPETITION!

The only way to memorize the pre-trip is to repeat it over and over. Start with the engine area and work your way around the truck and finally inside the cab.

There is no way around consistent repetition. The more you do it the more you will memorize it. It’s just that simple.

Now that we have established how important repetition is I want you go through the rest of this list and figure out which method (or methods) works best for you and then repeat it over and over.

2. Record Someone Else

You can use YouTube to find a video of someone doing a pretrip and for the most part they work pretty well (more about YouTube later).

Take it a step further though. Ask someone (like and instructor or friend) to do a pre-trip and video record them.

While they are doing it try to use the zoom function on your camera so that you know what the parts look like and what is being checked.

Students that I come across have said that this method works really well because you have quality video and audio. Just watch your recording over and over and this stuff will be engraved in your brain.

Just make sure you are absolutely sure that the person you record knows what they are doing and are showing you everything. You don’t want to watch a video that skips anything that will be on the test.

3. Smaller Chunks

Break down the pre-trip into smaller chunks so that it is not overwhelming. If you think about memorizing everything at once it will be a daunting task.

My suggestion is you learn your air brakes first, then the inside of the cab, the engine compartment, and then the rest of the truck. You can chose any order that you want to as long as it helps you out.

Memorize each part and then tie it all together. You will find that learning the pre-trip is much easier if you do it this way.

4. Use Your Imagination

Do this while in bed before you fall asleep. Warning: the pre-trip is going to consume a lot of your attention during training, even while you sleep!

When you wake up go through a video you found on YouTube or the one you recorded (see #2) and correct any errors you made.

5. Find A Truck

It really helps if you have access to a truck. Pictures alone are not enough. Most of you are probably getting your training through a private school, company sponsored training , or community college.

All of these will give you access to an actual truck and should be taking time each day to practice the pre-trip.

Take advantage of this time with the truck to practice your pre-trip as much as possible. When class ends try to stick around to get in some extra practice, this could be the difference between passing and failing.

6. Watch A Pre-Trip Video On YouTube (not straight through)

There are a lot of videos on YouTube that you can choose from. Let me save you some time, these two (below) is the best because it has good audio and video quality, is accurate, and is easy to follow.

Don’t watch the video straight through over and over. Like I mentioned earlier you should chunk it into smaller sections.

Watch a section, pause it, and list off the names of the parts and things to look for. Play it again to see if you are getting them correct. When you finish one section go on to another section until you finish it.

Don’t move on to a new section until you have memorized the section you started. When you complete all the sections you should be able to watch the whole pre-trip and repeat everything on it from start to finish.

If you want to challenge yourself a little try mixing up the sections so that the sections that was last is now first. This will let you know if you are really memorizing everything.

7. Use A Checklist

Probably the most popular ways to memorize the pre-trip is to use a checklist. No doubt that wherever you are getting your training at is already giving you a checklist to use.

Use it. A lot.

Not all checklists are done in the same order but they should all cover the same stuff. I like this one here (printable PDF document) by the people at Trucking Truth , it’s easy to follow and is accurate.

Every possible thing that you will need to identify during the pre-trip is on this checklist.

8. Use Pictures/Diagrams

There are a ton of picture resources out there that will help you memorize the test. Just do a search for “cdl pre-trip inspection pictures” and you will find a ton of stuff.

The picture I like most are these (link to PDF) by Driver Solutions. The pictures are easy to see and distinct arrows are used to point to each part. Along with pictures is an explanation of what to look for and what to say for each individual part.

What Is The Pre-Trip Inspection?

The pre-trip inspection is an inspection of the commercial vehicle including the cab, engine compartment, and exterior.

A driver of a commercial vehicle is required, by federal law, to complete one every day before driving the vehicle and at least once in a 24 hour period. Every single time you begin driving your truck you will have to complete a pre-trip.

The purpose of it is to make sure that the vehicle is safe to drive.

This gives you a chance to get whatever is wrong fixed. If you miss something and are inspected it could result in citations by the DOT.

A lot of drivers find it to be a pain in the rear but you really need to do it every single time you drive your truck. Don’t listen to the irresponsible driver at the truck stop that tells you it’s okay to skip it. It’s not okay.

How Long Does An Inspection Take?

A pre-trip usually takes about 15-45 minutes to complete. It really depends on the type of truck you are inspecting and your experience.

After several years of driving it’s inevitable that your pre-trip is going to be quicker because you are better at doing it and you know what to look for.

As a new driver you should take your time and make sure you do it right. Make it a habit to always conduct a thorough inspection so that you run into less problems while on the road.

What To Say During The Pre-Trip Test

Knowing what to say is important during the test. There are some specific language the person testing you is going to be listening for. More than likely you already heard these phrases but here is an easy way to remember what to say:

PMS— Properly Mounted, Secure ABC— Abrasions, Bulges, Cuts CBB— Cracked, Bent, Broken

There are some tricks that you can use to make sure you say the right thing, here they are: 1 . If its mounted (almost everything is) use the words, “Properly Mounted, Secure” (PMS) 2. If its rubber use the words, “Abrasions, Bulges, Cuts” (ABC) 3. If it’s metal or another hard surface use the words, “Cracked, Bent, Broken” (CBB) 4. If it has fluid or air going through it or in it remember to say, “Not Leaking”

This language shouldn’t be new to you, hopefully the school that is training you has already taught you this stuff.

What Should You Cover During The Pre-Trip?

The areas that you should cover include the coupling system, light check, in-cab inspection, engine compartment, trailer, and drivers door fuel area. Make sure that you are prepared for all of these.

Also, keep in mind that CDL schools/classes may cover the pre-trip in different orders. It’s okay though, they all cover the same stuff. The order that you practice is probably going to be different from someones in a different school/class.

There is no correct order as long as you memorize everything.

What Will Be Tested On The Actual State Pre-trip Inspection Test?

You will be required to perform a pre-trip for the light check, the in-cab inspection, and the coupling system. These 3 areas you have to complete.

After completing those 3 areas your examiner will have you perform one of the following: the engine compartment, trailer, drivers door fuel door, or the entire vehicle.

You will not know ahead of time which one the examiner will choose. This is why it is crucial that you know all the areas.

What Else You Can Do To Prepare?

Aside from the ways listed above to help you memorize the pre-trip there are some other things you can do.

One thing you can do is try answering some practice tests like these here from Trucking Truth. There are 5 free practice tests you can take.

I really find that these practice tests reinforce what you need to know for the real test. It’s worth your time try them out just to see how you do.

What If You Fail The Pre-Trip?

If you do fail the pre-trip you are able to retake it. Make sure you know why you failed the test, ask the inspector if he/she can specifically tell you what you did wrong.

This is usually never a problem because the inspectors want you to know what you missed so that you can pass the test the next time.

One more thing, don’t be embarrassed because you didn’t pass it on your first try! This happens to a lot of people! You are not the only person that will fail the pre-trip and you won’t be the last.

Study what it is that you missed/did wrong and pass it on your second attempt.

Extra Tips For Passing The Pre-Trip Test

Probably the most common reason people fail the pre-trip is because they are nervous.

The two things that will help you out the most is to always remember that the pre-trip is a verbal contact test.

As you start walking towards the vehicle you should already be looking for any leaks under it, broken marker lights, loose mirror brakes and anything else that seems out of place.

BE VERBAL! Your number one priority is to make sure the examiner knows that you know what you are talking about. The more you talk the greater your chances are to pass the test.

Even if it might seem you are going overboard just keep going. Examiners tend to like when testers are verbal.

http://www.truthabouttrucking.com/fls/Pre_Trip_Inspection.pd

CONTACT! The second most important thing you can do is make contact with the item you are describing. For example, as you are explaining the radiator brace you need to make sure you point to or put your hand on the brace as well.

Your examiner wants to make sure that you actually know what the item is that you are explaining.

Make sure you are pointing the the correct item though! Don’t describe the radiator brace while pointing to the turbo!

Again, make sure you are VERBAL and CONTACT every single item (correctly) that you are describing.

Now go pass that test! Good luck driver!

Privacy Policy

COPYRIGHT © 2019 CDL TRAINING SPOT

CDL Class A w/Air Pre-Trip Inspection Checklist

Pre-trip inspection class a with air brakes.

Once you have completed the federally required Entry Level Driver Training (ELDT) theory and behind the wheel (road and range) mandated training, the next step to gaining your Commercial Driver's License (CDL) are the three basic skills formal tests . The three test and the order for which they must be completed are as follows: the Pre-Trip, Basic Skills (backing manurers), and the Road Course. This article discusses the Pre-Trip Inspection.

During the Pre-Trip Inspection skills test for the air brake equipped Class A Tractor and Trailer, you will have about 95 items to check on a tractor with 2 axles and 2 trailer axles.

A full step by step video demonstration of the Pre-trip inspection procedure. A written checklist can be found below the video to help with your study.

When you are completing the inspection test, you must name and point to or touch each item, and fully explain what you are inspecting (you must ensure the tester knows what you are referring to). You will be graded on whether you know what to check each part for, and not necessarily that you know the specific names of the parts. You will have to check each axle as outlined. There is no order or sequence to the test. If you miss a part, you can go back and identify it.

You cannot use any assistance during the Pre-Trip Inspection Test required for gaining your CDL -- you will be completing the inspection checklist by memory, so ensure you know your stuff!

At the end of this checklist, you will find procedural videos to assist you in understanding the requirements for successfully completing the Class A with Air Brakes Pre-Trip Inspection. Utilizing both the written checklist and the demonstration videos in your study will greatly increase your chance of achieving a passing grade on the Pre-Trip Inspection portion of your Basic Skills test.

Pre-Trip Inspection Class A Checklist Items

This order starts in the engine compartment and inspects only the axles on the driver’s side of the truck. The test requires you to only inspect the driver side unless the item is only on the passenger side; for example, parts in engine compartment and exhaust system.

Engine Compartment

- make sure level is between add and full.

- level is sufficient for operation, between hot and cold mark.

- level is between add and full.

- must say that pump is gear driven, working properly.

- not leaking, securely mounted.

- securely mounted, bolts tight, not leaking.

- belt driven, belt not cracked or frayed, tension is between ½” and ¾”.

- securely mounted, bolts tight.

- wire secure into back of alternator.

- secure to engine, bolts tight, hoses secure.

- must say that it is gear driven.

- works properly, not leaking.

- check under vehicle for oil puddles.

- check motor for excessive leaks.

- check hoses for splits, cuts.

- make sure all clamps are tight.

- check all hoses for leaks.

- make sure to check both sides of engine for leaks/hoses.

Front Truck Axle

- secure, bolts tight.

- not leaking.

- not cut, pinched or leaking.

- fittings are secure, not cracked or broken.

- not bent, bolts tight, no cracks, cotter pins in place, sockets are not worn or loose.

- must check from steering box to wheel.

- none broken.

- all in alignment.

- not rusted.

- nuts tight.

- not broke or rusted.

- not shifted.

- check front and rear mount for cracks and rust.

- check for tight or missing bolts.

- make sure bushings are not torn or missing.

- straight (not bent).

- bolts tight.

- not kinked, cut, swollen or leaking.

- fittings secure.

- not bent, broke or leaking.

- not cracked, dented, rusted or leaking.

- must check clamp ; secure, tight and in place.

- pins in place holding slack adjuster to push rod.

- straight, not broken.

- no more than 1”adjustment (movement) on the push rod .

- Straight, not broken.

- no holes, cracks or welds.

- bolts tight, none missing.

- no signs of grease or oil.

- shoes are sufficient, more than ¼” pad.

- no cracks, no chipped pads.

- no fluid, grease or oil.

- 4/32” tread depth.

- no cuts or bubbles on side walls.

- check top of tire for even wear and flat spots.

- check pressure with gauge.

- check valve stem is not cracked, broke, leaking or twisted and secured with cap.

- no aftermarket welds.

- none missing.

- not loose, no cracks or distorted lug bolt holes.

- no signs of rust trails.

- no loose or missing bolts.

- proper fluid level (if sight glass is installed).

Side of Cab

- door hinges are secure, bolts tight.

- handle works, no damage to side.

- seal is in tack and not torn.

- opens and closes properly.

- securely mounted, brackets not damages, bolts in place.

- mirror is clean, and not broken.

- no fluid or debris on steps.

- straps are secure

- cap is on tight with chain and seal in place.

- must check tank & cap for leaking.

- bracket secure.

- cap is on tight.

- no signs of soot (leaking).

- securely mounted.

- all clamps are tight.

- must check whole exhaust system from the turbo to the top of stack.

Rear of Cab

- no cracks, straight.

- bolts are all tight.

- must also check cross members for same.

- not pinched, cracked, swollen.

- securely hanging, not rubbing.

- metal fittings at tractor secure, not broken.

- rubber grommets at trailer not dirty, pinched or leaking air.

- metal fittings at trailer secure, not broken.

- must check at both ends — tractor and trailer .

- secure, plugged in tight (locked or latched if applicable).

- lines not repaired, taped, cut or pinched.

- securely hanging, not rubbing on frame or cat walk.

- straight, no cracks, bolts are tight.

- U-joint bolts tight and free of foreign objects.

- bolts are tight, not slippery.

Fifth Wheel

- none missing, all tight.

- (bolted to frame) bolts tight, none are missing, not cracked, straight.

- (raised area) no cracks or broken welds, straight.

- in locked (all the way in) position, locking pin is secure if equipped.

- must check there is no gap between 5th wheel plate and trailer apron.

- not broke, dented, chipped, flat.

- sufficiently greased.

- pin is in place at pivot point (side).

- no holes, cracks, chipped and flat.

- look in back of 5th wheel to make sure that jaws are locked around king pin.

- straight, not broke or chipped.

- locking pins fully extended through gear or locking device.

- air-line not kinked, pinched or leaking (if equipped).

- distance between tractor and trailer sufficient for turning without hitting.

Rear Truck Axle

- bushing is not missing or damaged.

- check front and rear mount for cracks.

- not kinked, pinched, weathered or leaking, securely mounted.

- straight, securely mounted, not leaking.

- fitting is secure.

- not cracked or rusted or leaking.

- clamp is secure, tight and in place (must check to get credit).

- no more than 1” adjustment (movement) on the push rod with brakes released (double chamber).

- no holes, cracks, or welds.

- smooth surface, not dented.

- no cracked or chipped pads.

- 2/32” tread depth.

- check pressure with a gauge.

- check valve stem is secure, not cracked, leaking or twisted, and cap is in place.

- no cracks, rust or aftermarket welds.

- none missing, not loose, no signs of rust trails.

- no cracks or distorted lug bolt holes.

- must check there is no debris between tires.

- tires are evenly spaced.

- rims flush (butted) together.

- no cracks or broken welds.

- cross members are straight.

- no holes in trailer floor.

- fully raised.

- no broken welds or cracks, bolts are tight on framing.

- crank handle is secured.

- feet are secure and not broken.

- trailer front has no cracks, holes or dents.

- will secure load in sudden stop.

- no missing bolts or rivets.

Front Rear Trailer Axle-treat same as truck axles .

Rear of Trailer

- opens and closes.

- no cracks, not bent.

- hinge secure, not broken.

- seal in place, not torn (if equipped).

- mud flaps are not torn.

- bolted securely.

- length is sufficient.

Cab Compartment/Engine Start (need to demonstrate all mechanisms)

- if equipped, ABS light should go on and off when you turn the key on.

- if ABS light stays on, then the ABS system is not working properly.

- if equipped, DEF light should go on and off when you turn the key on.

- if DEF light stays on, then there is less than 1/8 fluid level in the DEF tank.

- push in clutch & make sure shifter is in neutral before starting engine.

- if automatic transmission make sure vehicle is in neutral.

- needle moves, check temperature gauge for operation and in safe range.

- check voltmeter for operation and in safe range.

- needle indicating charging.

- needle moves, check oil pressure gauge for operation and in safe range.

- working properly, pressure builds to 120 psi — MUST SAY: governor cut out, or purges.

- must have air pressure built up, and check parking brake by applying and putting truck in low gear or drive (for automatic) and try to move (gently).

- must check both tractor and trailer parking brake individually.

- pull forward at 5 mph and stop with foot brake, check for no pull left or right.

- must be clean.

- no cracks, chips or stickers.

- seal is secure with no leaks.

- no stickers.

- mirrors are adjusted.

- operate properly (must turn on).

- rubber blades are not cracked with good contact to windshield.

- medal arms are secure, no damage.

- washer fluid operates (squirts).

- on dash, check left & right turn arrow.

- 4 way flashers.

- high/low beam indicator.

- blow air and electric horn.

- must turn to hot and feel for air from vents.

- turn on defroster to make sure it works properly.

- feel for air to blow from vent at windshield.

- Reflective.

- spare fuses or breakers (whichever the truck is equipped with).

- not cut, frayed or torn.

- securely mounted at seat, shoulder and floor ( all points ).

- latches securely.

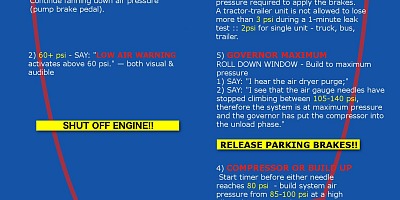

- Must build air pressure to governor cut-out or purges.

- turn off engine, then turn key to on position .

- release both parking brakes (push in truck & trailer valves).

- apply foot brake & keep pressure and LET THE PRESSURE SETTLE. Apply for 1 minute –cannot lose more than 4 pounds in 1 minute, and listen for leaks (must hold for full, timed minute).

- say that low air buzzer will come on at approximately 55 to 60 PSI, pump foot brake (fan) so buzzer will sound.

- say that parking brake will pop out at approximately 20 to 40 PSI, pump foot brake (fan) so buttons pop.

Lights—Amber on Front, Red on Rear ( MUST CHECK ALL LIGHTS , must say color and describe light condition).

- Lights (front of vehicle AMBER )-headlights (high & low beam), right/left turn signal, 4 way flashers, clearance, must turn on, clean, not broken, operating properly.

- Lights (front side of tractor AMBER )-right/left turn signal, put on emergency, flashers, make sure working, amber lenses, not broken, clean.

- Lights (rear of tractor RED )-right/left turn signal, put on 4 way flashers, clearance and brake lights, red lenses, not broken, clean.

- Lights (front side of trailer AMBER )-must turn on, working properly, amber lenses, not broken, clean.

- Lights (rear side of trailer RED )-must turn on, working properly, red lenses, not broken, clean.

- Lights (rear of trailer RED )-must turn on, right/left turn signal, emergency flashers, clearance and brake lights, red lenses, not broken, clean.

Videos are a great way to supplement your learning experience, but attending a certified, formalized truck driving school would be a way of ensuring you gain the knowledge and skills required to achieve your Commercial Driver’s License (CDL). Nothing can replace the actual behind the wheel driving experience! Classes convene regularly, so call (352)794-6080 , and reserve your drive time , now!

Site Navigation

- SMG of Crystal River

- CDL Testing

CDL Testing and Prep

- Steps to Getting Your CDL

- Class A CDL Pre-Trip Inspection w/Air

- Class A CDL Pre-Trip Inspection w/o Air

- Dump Truck CDL Pre-Trip Inspection Class B

- Passenger Bus CDL Pre-Trip Inspection Class B

- Driver's On-road Practical Test

- Commercial Driving Behavior

- CDL Driver Control Skills Test

- Instructional Videos

All CDL Testing & Training

All SMG CDL testing and training is initiated and completed at Interstate Commercial Driving School (ICDS) located at:

SMG Contact Information:

Tel: (352)795-7170

Fax: (352)795-8723

© SMG, Inc . All Rights Reserved.

Mastering Air Brakes: The Ultimate Guide to Acing Your CDL Air Brake Test with ProDriverU

November 17, 2023.

When it comes to obtaining a Commercial Driver’s License (CDL), understanding air brakes isn’t just a part of the curriculum — it’s a critical safety component. Fail to understand air brakes, and you put yourself — and everyone else on the road — at risk. That’s where ProDriverU comes into play. With years of expertise in CDL training, we provide comprehensive educational resources to help you not just pass the air brake test but understand it inside out.

In this article, we’ll explain how air brakes work, discuss why you need an air brake endorsement, share some foolproof tips for passing the CDL air brake test, and more. So, whether you’re preparing for the test or looking to refresh your knowledge, you’re in the right place.

The Basics of Air Brakes

Air brakes are not just any brakes; they are a specialized braking system designed for heavy-duty vehicles. While your regular car uses hydraulic brakes, air brakes employ compressed air for more robust and effective stopping power. Why? Because large vehicles like semi-trucks and buses have greater mass and momentum on the road. The capacity to halt these vehicles safely is essential, not just for the driver but also for the safety of everyone on the road.

Mechanics of Air Brakes

Understanding air brakes doesn’t require a mechanical engineering degree. In the simplest terms, when you press the brake pedal, air is channeled into the brake chamber creating pressure. This pressure activates the brake shoes or pads which, in turn, slow down the vehicle. The key takeaway is that compressed air serves as the ‘muscle’ behind the braking action, making it possible to control large vehicles effectively.

Types of Vehicles That Require Air Brakes

Air brakes are commonly found in:

- Semi-Trucks : Given their size and the kind of loads they carry, air brakes are non-negotiable.

- Buses : Whether it’s a school bus or a long-distance coach, the safety of passengers is paramount, making air brakes essential.

- Heavy-Duty Construction Vehicles : Think dump trucks and heavy machinery where failing brakes are not an option.

- Emergency Vehicles : For fire engines and ambulances, reliable braking can literally be a matter of life and death.

Understanding the basics of air brakes is your first step towards acing that CDL air brake test, and more importantly, becoming a safer, more responsible driver. To get ahead, check out the specialized training modules offered by ProDriverU .

Why You Need an Air Brake Endorsement

Legal requirements.

If you’re planning on operating a vehicle with air brakes, an air brake endorsement isn’t just recommended; it’s legally required. Federal and state laws mandate that any driver operating a heavy-duty vehicle equipped with air brakes must possess an air brake endorsement on their Commercial Driver’s License (CDL). This endorsement signifies that you have passed the necessary tests and possess the knowledge and skills required to safely operate vehicles with air brake systems.

Safety Concerns

Safety is the driving force behind this legal requirement. Air brake systems are complex and offer different handling characteristics compared to standard hydraulic brakes. Misunderstanding or misuse can lead to brake failure or reduced braking efficiency, potentially causing severe accidents. An air brake endorsement assures that you’ve undergone specific training and evaluation, confirming your aptitude in handling these systems safely.

In essence, possessing an air brake endorsement is both a legal and safety obligation that proves your capability to operate large, heavy-duty vehicles with air brakes effectively. It’s not just a piece of paper but a stamp of assurance for you, your employer, and everyone else on the road. To help you achieve this milestone, ProDriverU’s specialized courses are tailored to prepare you thoroughly.

Preparing for Your CDL Air Brake Test

Taking the CDL air brake test is not just another box to tick on your way to becoming a commercial driver. It’s a crucial step that determines whether you’re qualified to drive vehicles with air brake systems. Not preparing adequately can not only result in a failed test but also pose significant safety risks when you’re finally on the road. Knowing the ins and outs of air brakes is essential to not only passing the test but also to operating heavy vehicles safely.

Study Materials

To prepare efficiently, you’ll need a comprehensive set of study materials that cover all aspects of air brake systems. While there are various resources available, opting for trusted providers like ProDriverU ensures you’re getting the most accurate and up-to-date information. Our ELDT Training courses include dedicated modules on air brakes, designed by industry experts to equip you with the necessary knowledge.

Practice Tests

Besides studying, it’s crucial to test your understanding through practice tests. Practice tests simulate the actual CDL air brake test, giving you a clear idea of what to expect. They not only assess your knowledge but also help you improve time management skills, a vital aspect of passing the test. ProDriverU offers a range of practice tests specifically designed to prepare you for the air brake endorsement exam.

By combining comprehensive study materials and practice tests, you’ll be more than just prepared — you’ll be confident. And in tests like these, confidence can make all the difference. So why wait? Start your preparation journey today with ProDriverU and be one step closer to acing your CDL air brake test.

Tips and Tricks for Acing the CDL Air Brake Test

Understanding the components.

Navigating the CDL air brake test can be daunting, but a clear understanding of what to expect can demystify the process. Typically, the test has two main components: a written exam that tests your theoretical understanding and a practical skills test that evaluates your hands-on abilities. The written section covers topics ranging from brake system components to safety protocols. The practical test, on the other hand, will require you to demonstrate competency in pre-trip inspection, brake adjustment, and vehicle control.

Practical Skills to Master

Mastering certain skills can make a world of difference in how you perform on the test. Firstly, get comfortable with pre-trip inspection procedures. This involves checking air leaks, assessing the air compressor, and examining brake components for wear and tear. Secondly, practice adjusting the brake pushrod to ensure optimal braking. Lastly, learn to effectively manage air pressure levels in the brake system to maintain control during your drive.

Test-Taking Strategies

Here are some proven strategies to help you excel in the test:

- Time Management : Use your time wisely during the written test. Read each question carefully and don’t rush.

- Practice, Practice, Practice : The more you practice, the more comfortable you will be. Take multiple practice tests to familiarize yourself with the type of questions that may appear.

- Mindfulness : Stay calm and focused. Nervousness can lead to simple mistakes.

Armed with these tips and a thorough understanding of air brakes, you are on the right track to acing the CDL air brake test.

Real-Life Applications: Using Air Brakes Effectively

Air brakes are not just about passing a test. They are an essential part of daily operations in large commercial vehicles. Here are some real-world tips for using air brakes effectively:

- Gradual Braking : Apply the brakes gently to reduce the risk of skidding, especially on slippery roads.

- Monitor Air Pressure : Always keep an eye on the air pressure gauges. Low air pressure can impair your braking efficiency.

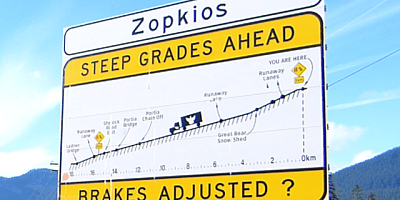

- Use Engine Brakes : In downhill conditions, use engine brakes to assist your air brakes, reducing the risk of overheating.

Maintenance for Long-Term Efficiency

Just like any other vehicle component, air brakes require regular maintenance for optimal functionality.

- Regular Inspection : Consistently inspect the brake linings, hoses, and drums for wear and tear.

- Check for Leaks : Air leaks can lead to reduced braking power. Make it a routine to check for hissing sounds or leaks.

- Adjust the Brakes : Improperly adjusted brakes can cause dragging or over-adjustment, affecting performance.

Understanding real-world applications and maintenance requirements can help ensure you are not just qualified but proficient in the use of air brakes.

FAQ Section: Everything You Need to Know

What is an air brake endorsement.