- Europe Tours

- Switzerland Tours

- Tour Operators

Top Tour Operators and Travel Agencies in Switzerland 2024/2025

Top Tour Operators and Travel Agencies in Switzerland. Below you will find 18 of the best tour operators and travel agencies in Switzerland offering in total 111 tours and holidays through-out Switzerland. Combined they have received 159 customer reviews and an average rating of 5 out of 5 stars. The top tour activities offered in Switzerland are: Sightseeing, attractions, culture and history, Wildlife, landscapes and nature & Adventure and sport.

- Tours in Switzerland

- Switzerland Travel Guide

- Best Time To Visit Switzerland

18 Tour Operators in Switzerland with 159 Reviews

Intrepid Travel

- Address 380 Lonsdale Street, Melbourne, Australia

- Response Rate 90%

- Response Time 2 hours

- Best-in-Class Top 5% of companies

- Excellent Service Top 10% of companies

- Superior Service Top 15% of companies

Grand Cuvée Tours

- Address Maistrova ulica 2a, Menges, Slovenia

- Response Rate 99%

Luxury Gold

- Address 33 Kern Road, Toronto, Canada

- Response Rate 60%

- Response Time 1 hour

Walkers' Britain

- Address 1B Osiers Road, London, England

- Response Rate 83%

Exodus Travels

- Address Grange Mills, Weir Road, London, England

- Response Rate 85%

- Response Time 3 hours

Tweet World Travel

- Address 8/587-591, B27, Magill SA, Australia

- Response Rate 93%

- Address Picquet House, St Peter Port, Guernsey, London, England

Insight Vacations

- Response Rate 86%

- Address 1B Osiers Road, Wandsworth, London, England

- Address Nelson House, 55-59 Victoria Rd, Farnborough, England

- Response Rate 95%

Scenic Luxury Cruises and Tours

- Address 15/56 Pitt St, Sydney, Australia

- Response Rate 74%

Indus Travels

- Address 233, 11951 Hammersmith Way, Richmond, Canada

- Response Rate 98%

CroisiEurope

- Address 12 Rue De La Division Leclerc, Nedre Rhin, France

Collette Tours

- Address 162 Middle Street, Pawtucket, Rhode Island, USA

Traveling to Switzerland? Chat with a local travel specialist in Switzerland who can help organize your trip.

Switzerland Tour Reviews

- Carah Emory

- Switzerland budget tours

- Eco tours in Switzerland

- Switzerland guided tours

- Switzerland family tour packages

- Switzerland luxury tours

- Switzerland private tours

- Switzerland self-guided tours

- Switzerland small group tours

- Switzerland solo trips

- Switzerland tailor-made vacation packages

- Switzerland tours for senior citizens

- Switzerland tours for young adults

- Switzerland group tours

- Switzerland last minute deals

- Switzerland travel deals

Upcoming Departures

- Summer 2024/2025

- Winter 2024/2025

- Spring 2025

- August 2024

- September 2024

- October 2024

- November 2024

- December 2024

- January 2025

- February 2025

- August 2025

- September 2025

- October 2025

- November 2025

Best price guaranteed - No booking fees

Sign-in to unlock instant trip discounts. Create wish lists and save up to USD 1,500.

+41 (0)44 710 50 50 (7:00 - 21:00)

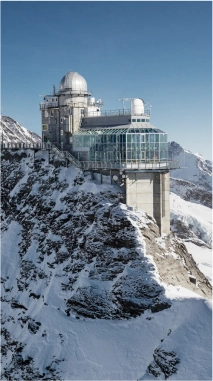

Jungfraujoch – Top of Europe

Don’t miss the highlight of any Swiss holiday and join us for a full-day excursion to the Jungfraujoch - Top of Europe!

Titlis - Eternal Snow & Glacier

Take the revolving Rotair cable car up to Mt Titlis, where a magical winter wonderland awaits you all year round!

Pilatus - The Golden Round Trip

Take the Dragon Ride cable car to Mt Pilatus and descend by the world’s steepest cogwheel train before taking a relaxing lake cruise!

Zurich & Surroundings City Tour

Combine the fascinating city of Zurich with its beautiful surroundings on our extended afternoon sightseeing tour!

Rhine Falls & Stein am Rhein

Visit the Rhine Falls, Europe’s biggest waterfall, and the medieval town of Stein am Rhein on an afternoon excursion from Zurich!

Zurich with Cruise & Lindt Home of Chocolate

Discover Zurich on a versatile city tour including a boat trip on Lake Zurich and a visit of the Lindt Home of Chocolate!

show all tours

Tour Categories

Sightseeing Tours

Discover our sightseeing tours with daily departures from zurich, lucerne and interlaken.

Browse our wide selection from city tours to full day mountain excursions with a professional tour guide introducing you to the most beautiful destinations in the German-speaking part of Switzerland.

Premium Small Group Tours

Discover our premium small group tours with max. 16 guests for a more personal touch.

Enjoy authentic experiences with hand-picked local providers at destinations off the beaten track from the comfort of a Mercedes minibus conducted by an experienced driver-guide.

Multi-Day Tours

Discover our fine selection of multi-day tours and make the most out of your stay.

Combine our most popular mountain excursions with an unforgettable overnight stay including half board or breakfast and enjoy ample time at leisure to explore the most beautiful Swiss destinations.

Private Guided Tours of Switzerland

Welcome to typically swiss tours.

Our Best Selling Tours

MOST POPULAR

Spend a day visiting some beautiful natural spots und the shadow of the Jungfrau in Switzerland`s most breath-taking region

SPECTACULAR TOUR

Go up one of Switzerland`s iconic mountains by cog wheel and cable car and tour Switzerland`s prettiest town

BREATH-TAKING

Spend a whole week travelling through the heart of Switzerland and visit some of it`s iconic and most spectacular places

Click on this video to see what an actual Typically Swiss Tour looks like...

We are Friendly

Our aim is that your whole Swiss tours experience with us is a positive one, not just on tour but in the booking phase too. We will spend as much time as required to match the places with your wishes and on tour, our driver guide will get to know your group well, so he can advise on the plethora of things to see on your tour. Through our friendly approach, we aim to make our guests as comfortable as possible.

We are Personal

For the duration of your tour, you are our focus. Your guided tour of Switzerland will be just your group driven in a comfortable Mercedes Viano by our driver guide. We go out of our way to make sure you have simply the best possible day out during a tour with us. From your first contact with us, until you return to your hotel, we will personally ensure that your tour experience surpasses any expectation you may have.

We are Flexible

Our tours are designed to show you the best places in Switzerland. However we are happy to hear from you if you want to change a destination or visit somewhere else. We have no problems in changing itineraries to suit guests so that you get to see the places you want to see and naturally on route, we can stop or make changes to our planned journey so you do not miss anything of interest.

Term and Condition

Booking instructions and conditions: Age Policy Typically Swiss Tours welcomes any adult on all experiences. Accompanying children are also welcome on our tours however, they must be accompanied and supervised at all times by an adult other than a Typically Swiss Tours guide.

Travel Insurance Travel Insurance is NOT included in the cost of your booking. We strongly recommend that you purchase an appropriate level of travel insurance to provide you with coverage for any financial loss incurred as a result of cancellation of your booking due to unforeseen circumstances. We also recommend that you consider insurance to cover costs incurred by you for any medical expenses resulting from injury or illness, medical or ambulance transportation, damage to or loss of baggage, loss or theft of valuables (including phones and cameras) and for delays and/or interruptions to your travel plans.

Health & Safety

By placing a booking with Typically Swiss Tours, you agree to the following • I and my travel companions are solely responsible for our health and safety. • I acknowledge that I and my travel companions are physically capable of participating in and completing the activities and I/we understand that some activities may involve a level of physical exertion to participate. • I acknowledge that, by informing Typically Swiss Tours of any medical concerns in advance of my booked tour, it may be possible to adapt the activities to ensure my/our continued health and safety. • I also acknowledge that if I do not advise or discuss with Typically Swiss Tours at the time of booking or prior to departure about any medical or physical conditions that I or my travel companions have, that I/we may need to forego participation in some of the planned activities unless a suitable alternative activity can be arranged during the tour.

Weather conditions

Under no circumstances can Typically Swiss Tours be held responsible for poor weather conditions. Tours will proceed with adaptations to suit the conditions. With sufficient notice we can assist you by amending your booking, however our standard amendments and cancellation policy will remain.

• Payments are accepted in Swiss Francs. • Bookings are not confirmed without payment of the required deposit as below. • Non-payment of any amounts when due, risks cancellation of your booking without any refund of prior payments made. Notification of this action will be sent to the email address provided.

Deposit and Final Payment • Day tours • A 25% deposit is required at the time of booking when booked 30+ days prior to the date of tour. • Full payment of the balance is due 30 days prior to the date of tour. In some cases, cash will be accepted on the day. • If booked within 30 days of the date booked, full payment is required at the time of booking.

• Multi-day tours. • A 25% deposit is required at the time of booking. • Full payment of the balance is due 30 days prior to the date of departure. • For bookings placed 30 or less days before departure date, full payment is required at the time of booking.

Booking Amendments and Cancellation – COVID update included

We recognise that due to the pandemic, our policies need to reflect this. We are happy to answer any questions you may have on this subject on [email protected] or 0041 79 286 0451

Amendments We understand that you may need to make changes to your travel plans, possibly at short notice. We ask you to contact us to discuss your circumstances with us, allowing us to assist in whatever way we can.

There is no additional charge to amend your booking (e.g. change of date), if and when available. However we ask you to advise us of any intended change with as much notice as possible. It’s important to be aware that some fees or additional costs may result from amendment to the itinerary planned. You will be informed of any such additional costs when known. Cancellations Before cancelling your booking, we encourage you to contact us to discuss before doing so, because alternative options may be available (such as rescheduling or voucher for future use). If you need to cancel your booking, you must provide written notification outlining your reasons for cancellation to [email protected] . The date received in our inbox will be the effective date of cancellation, unless your intention to cancel has been previously communicated to us. Upon receipt of your fully completed form and supporting documentation, we will process your cancellation request and issue a refund (if applicable) as soon as practicable. If cancellation falls within our terms of cancellation, Typically Swiss Tours management always uses fair and reasonable discretion on a case by case basis. These are the Typically Swiss Tours cancellation conditions.

As a general rule the following conditions apply

Before 30 days prior 90% refund of cost of tour. Before 21 days prior of the tour date 50 % refund of cost of tour. 21 days and less, no refund.

In case of accident or sickness, the customer has to provide a medical certificate to prove why the tour must be cancelled. With a medical certificate, 90% of the tour fee will be refunded.

If Typically Swiss Tours needs to cancel your tour, all payments made by you to Typically Swiss Tours for that tour will be refunded in full.

If the customer doesn’t show up at the agreed time, TST is not responsible if the customer misses the tour. However, TST will be entitled to charge the full amount of the booked tour. There is no additional charge to amend your booking (e.g. change of date), however we ask you to advise us of any intended change with as much notice as possible. It’s important to be aware that some fees or additional costs may result from amendment to the itinerary planned. You will be informed of any such additional costs when known. Cancellations Before cancelling your booking, we encourage you to contact us to discuss before doing so, because alternative options may be available (such as rescheduling or voucher for future use). If you need to cancel your booking, you must provide written notification outlining your reasons for cancellation to [email protected] . The date received in our inbox will be the effective date of cancellation, unless your intention to cancel has been previously communicated to us. Upon receipt of your fully completed form and supporting documentation, we will process your cancellation request and issue a refund (if applicable) as soon as practicable. If cancellation falls within our terms of cancellation, Typically Swiss Tours management always uses fair and reasonable discretion on a case by case basis. If Typically Swiss Tours needs to cancel your tour, tuition session or retreat due to unforeseen circumstances, and alternative arrangements cannot be made, all payments made by you to Typically Swiss Tours for that tour, will be refunded.

If the customer doesn’t show up at the agreed time, TST is not responsible if the customer misses the tour. However, TST will be entitled to charge the full amount of the booked tour.

Applicable Law/Court of Jurisdiction:

All legal relationships between the participant and TST are subject to Swiss law. Bern, Switzerland, has been agreed upon as the place of exclusive jurisdiction.

Private Policy

Typically Swiss Tours, operates using the following privacy policy, This Privacy policy explains how we use any personal information we collect about you.

What information do we collect about you?

We collect information about you when you register with us or place an order for products or services. We also collect information when you voluntary complete customer surveys, provide feedback and compete in competitions. Website usage information is collected using cookies.

How will we use the information about you?

We collect information about you to process your order, manage your account and, if you agree, to email you about other products and services we think may be of interest to you. We use your information collected form our website to personalise your repeat visits to our website. Typically Swiss Tours will not share your information for marketing purposes with other companies.

We would like to send you information about our products and services and other companies in our group which may be of interest to you. If you have consented to receive marketing, you may opt out at a later date. You have the right at any time to stop us from contacting you for marketing purposes. If you no longer wish to be contacted for marketing purposes, please email us at [email protected] and we will take you off our mailing list.

Access to your information and corrections

You have the right to request a copy of the information that we hold about you. If you would like a copy of some or all of your personal information, please write to us at the following address:- • [email protected] • Stirnrüti Strasse 64, 6048 Horw, Switzerland

We may make a small charge for this service. We want to make sure that your personal information is accurate and up to date. You may ask us to correct or remove information you think is inaccurate.

Cookies are text files places on your computer to collect standard internet log information and visitor behaviour information. This information is used to track the visitors use of the website and to compile statistical reports on website activity. For further information visit. http:/www.allaboutcookies.org/ You can set your browser not to accepts cookies and the above website tells you how to remove cookies from your browser. However, in a few cases some of our website features may not function as a result. Our website contains links to other websites. This Privacy policy only applies to Typically Swiss Tours websites so when you link to other websites you should check their own Privacy policies.

Changes to our Privacy Policy

We keep Privacy policy under regular review and we will place any updates on this web page. This privacy Policy was last updated on 21-02-19

How to contact us

Please contact us if you have any questions about our Privacy policy or information we hold about you: By Email : [email protected] By telephone: 0041 79 286 0451

SUBSCRIBE TO OUR MONTHLY NEWSLETTER Sign up for TST Newsletter and receive a free essential guide to Switzerland

We use cookies that are necessary for running the website and for providing you services. Additional cookies are only used if you consent to it. They serve statistical purposes or for displaying individual offers and ads. For more information, read our data protection statement and cookie policy .

By clicking "Agree" you consent to our use of cookies.

AI SWISS ITINERARY

- BUILD ITINERARY IN 30 SECONDS

Popular Packages by SWISS tours

Swiss Highlights

7 Nights / 8 Days

Chalet Style Holiday - Interlaken

Live it up in Lucerne

Glimpses of Switzerland & Paris

Tops of Switzerland

4 Nights / 5 Days

Magic of Glacier Express

6 Nights / 7 Days

How It Works

Select the cities with the duration of travel and proceed by entering your personal details.

We put together the best itinerary for you within seconds.

Customize the itinerary by adding nights or excursions to your package. Click on 'Get Trip Cost'.

Enter your dates of travel and the number of people travelling.

Review the itinerary, cost & inclusions and continue ahead to book your dream holiday.

Photo Gallery

What if I don’t travel due to Covid related reasons??

While booking the hotels & sightseeing’s, you can check the cancellation for each product. The hotels and conducted tours will have the refund policy mentioned and you may choose accordingly. The Swiss pass and mountain excursions have a 1 day prior cancellation policy.

Are these individual packages or group packages?

These are individual packages and not group.

A customized itinerary takes days to prepare and how do we do it in a few seconds?

- Our algorithm based itinerary gives you the best possible routing making sure you don’t back track along with giving you the best possible suggestions and recommendations. With automation, it only made it easier. The integrations with partners around the world make the user experience seamless along with giving you the best itinerary & pricing in just a few seconds. Moreover our itineraries have been made by specialists who have not only been to the destination but also many years of experience selling the destination.

Do I get instant confirmation?

Yes, our inventory is live, dynamic and gives you instant confirmations.

Can I customize the itinerary??

Yes, You can customize the itinerary by choosing from the cities listed along with the number of days you wish to travel for. You have the option of changing your accommodation depending on your budget. You also have the option of adding/ removing nights in the ‘route overview’. We also have mentioned the suggested / recommended excursions in the itinerary and you may pick & choose as per your wish making your itinerary fully customizable.

How do I know the inclusions in the itinerary?

You may click on ‘Includes’ option after you get the cost of your trip as per your dates of travel and you will see the inclusions in your itinerary.

How does one travel between the cities in the itinerary?

The travel between cities is with the all in one Swiss Travel Pass which is included in the package.

How do I save the quote?

After you get a quote for your desired itinerary, click on the ‘mail this option’. The quote will be sent to your email id and you can refer to it at a later date.

Does the package give me the best rates & availability?

The package rates are based on real time inventory which ensure our passengers can book what they see. In this fast changing world, the availability of hotels and excursions change by the minute, however with our top end technology & algorithm used, we give you dynamic & real time pricing enabling you to book what you see.

Can I make changes after paying full payment?

Yes, we are flexible in date change options, subject to availability at the time of booking. Also the rates may increase/decrease as per your new dates of travel.

Is the accommodation in hotels or apartments?

- The accommodation is based on centrally located hotels & apartments(wherever applicable). We have specially handpicked the accommodation so that you stay in city centre hotels.

Is visa cost included in the itinerary?

No, the visa cost is not included. However we give you visa assistance which includes giving you visa letter for the package confirmed which is part of the documents required for visa.

Do I need to give any personal documents in order to make any bookings?

We only need your names as per passport and pan card details to be filled in while making the booking.

Are meals included in the package?

The package includes breakfast (wherever specified). Lunch & dinners are not included in the package.

Are flights included in the package?

Flights are not included in the package. Our experts can help you book the flights or you may book it on your own.

How do I get in touch with your travel planner for expert advice?

You can call, email, chat with us or Whatsapp us to help you handcraft your dream holiday. We can even arrange a video call with our experts. Our friendly and professional personnel are well travelled to almost all regions of the country having first hand experience and with their expertise can ensure that the clients have the most memorable vacation.

- All Countries

- Switzerland

Switzerland Tours & Travel Packages 2024/2025

Our 675 most popular switzerland trips. compare tour itineraries from 111 tour companies. 1,584 reviews. 4.7/5 avg rating., popular switzerland tours.

Discover Switzerland, Austria & Bavaria - 2024

- Savor lunch at the 1,200-year-old St. Peter's Restaurant, Austria's oldest.

- Experience a fondue lunch in a picturesque alpine town.

- Dine on Tyrolean cuisine at a local restaurant.

- Witness the creation of Alpine music during an alphorn and yodeling demonstration.

- Relax and unwind with two leisurely 4-night stays.

Majestic Switzerland (Small Groups)

Best of Switzerland

- Choose your own adventure with two free days in the Jungfrau Region of the Swiss Alps. You can take these days as relaxed or as thrill-seeking as you want from your hotel homebase surrounded by mountain views.

- Find out why the Swiss are known around the world for their cheese and chocolate, with opportunities to sample both in La Gruyere region.

- Your locally based group leader will provide expert advice on how to make the most of your free time, as well as giving you orientation walks around each place so you can get your bearings.

- Take in the breathtaking alpine views from the summit of Mt Pilatus with your small group, reached via the steepest cogwheel railway in the world.

- With plenty of free time to explore at your own pace in Bern, you’ll discover why this city is considered one of the most beautiful and laidback capital cities in the world.

Splendours of Italy

Contrasts of Switzerland

- 1 Welcome Reception (WR)

- 7 Breakfast (B)

- 1 Lunch (L)

- 1 Be My Guest (BMG)

- 1 Farewell Dinner (FD)

Switzerland and Austria (2025 onward)

Walking and E-biking in the Swiss Alps

- Excellent walking and mountain biking made easier with E-bikes on this Swiss Alps multi activity holiday.

- Natural beauty at its finest, snow-capped mountains, beautiful glacial lakes, Alpine green slopes and meadows.

- Excellent family run hotel with new spa and sauna facilities, heated indoor swimming pool.

- Delicious high quality meals; plentiful breakfast, picnic or light restaurant lunches and 4 course dinner included every day.

Switzerland: Hidden Trails & Majestic Peaks - 2024

- Savor lunch at a family-owned restaurant followed by a wine tasting at a UNESCO World Heritage site.

- Dine at Mount Rigi during a farewell dinner with your fellow travelers.

- Discover the sweetest parts of Bern during a historic chocolate tour of the old town center.

- Discover Neuchâtel’s historic quarter and the treasures of the Belle Époque period.

- Visit the 13th-century Château de Boudry, where you’ll tour the Museum of Vine and Wine with a tasting.

All Switzerland , expedition cruises, self guided adventures and vacation packages. Find the best guided and expert planned vacation and holiday packages. Read more about Switzerland

Small Group Switzerland Tours

Switzerland & Italy in 16 days - Magic of the Alps & Eternal Cities - Charm

Hike the Tour du Mont Blanc

- The Tour du Mont Blanc is undoubtedly on of Europe’s most iconic and beautiful long-distance treks. Enjoy a week of hiking to the backdrop of snow-capped peaks, lakes, glaciers and mountain pastures.

- Comfortable and clean hotels & lodges are included each night, offering hearty meals and truly magnificent views of the surrounding mountains.

- Take a load off – literally! Your luggage will be transferred between your accommodation each day, meaning you’ll only have to carry a day pack, and your luggage will be waiting at your hotel.

- Filling breakfasts, picnic lunches and hearty dinners are included on each walking day – fuelling up for your explorations couldn’t be easier (or more delicious!).

- With an experienced and highly qualified International Mountain Leader by your side every step of the way, you can rest assured that you’re in safe hands.

Highlights of Mont Blanc

- Hiking parts of the famous Tour du Mont Blanc

- Alpine hospitality in spectacular mountain scenery

- Comfortable chalet hotel with indoor pool and sauna

Switzerland in 8 days - Enchanting Alps & Glacier Scenic Railway - Exoticca Group Charm

Switzerland & Central Europe in 18 days - Enchanting Alps & Central Europe - SUPERIOR BY BUS

Mont Blanc Highlights

- Walk surrounded by dramatic mountain scenery

- Stay in a comfortable alpine chalet

- Enjoy the shops, bars, restaurants and cafes of Chamonix

Mont Blanc to the Matterhorn

- Enjoy spectacular mountain scenery and some of the best walking in the Alps

- Challenge yourself among the highest concentration of 4,000m peaks in the Alps

- Visit the exciting Alpine towns of Chamonix and Zermatt

Best Switzerland Tours by Duration

Tours, Cruises & Private Trips

Best Switzerland Tours by Price

Top Switzerland Attractions

- Riding a cogway train through the magnificent Jungfrau Region

- Taking a tour of the Chillon Castle atop an island in Lake Geneva

- Conquering the peak of the Matterhorn on a guided alpine expedition

- Enjoying the breathtaking scenes of the Alps from the window of the Bernina Express

- Viewing the clock tower gate (Zytglogge) in Bern

- Taking a boat tour to see the Rhine falls

- Feeling the spray of the giant water fountain Jet d’Eau in Geneva

- Walking the Aare gorge near Interlaken

- Swooping down the side of Mount Pilatus in a cable car high above Lake Lucerne

Switzerland Tours & Travel

Switzerland Attractions & Landmarks Guide

Coronavirus update.

Travelers are required to undergo mandatory quarantine upon entering Switzerland, for those arriving from areas of high risk .

More important Covid-19 information for t ravelers

With its snow-covered alpine peaks, clear mountain lakes and rivers (with cruise boats), miles of beautifully marked and maintained hiking trails, vibrant cities, scenic railway trips that run on the dot, three separate cultures -- German, French and Italian -- and some of the world's cleanest lodgings and eateries, Switzerland combines nature and urbanity in a seamless way, like few other places in Europe .

Switzerland can lay a good claim to being the world’s most beautiful country.

With the snow-capped Swiss Alps and a raft of deep blue lakes gleaming in the sunshine, the pastoral hills with cows grazing peacefully on verdant slopes, the rivers coursing through steep gorges, and the well-maintained hiking trails snaking through them all, you can experience an outdoor setting with few rivals.

The villages, and even the largest cities, are neat as a pin and almost impossibly picturesque, with church steeples and medieval towers dominating the skylines and A-frame chalets dotting the hillsides.

You can ride boats across or around the lakes, ride trains large and small through the most scenic areas, and dine on delicious specialties such as rosti potatoes, raclette (a melted cheese dish), cheese fondue, and of course Swiss chocolate.

Everything runs on time in Switzerland, so if your cell phone is out of juice, you may want to pick up one of the famously accurate Swiss watches. City streetcars and buses run on the honor system for payment, but spot checks that find you without a ticket will cost you a small fortune in Swiss francs. (Swiss efficiency can have its drawbacks.)

Top Ten Cities to Visit in Switzerland

Zurich . Zurich is the largest city in Switzerland and the hotspot for nightlife, shopping, and museums. It is also the starting point for many tours and trips around Switzerland.

Geneva . Geneva is the headquarters for the Red Cross and sections of the United Nations, making it a global and progressive city. Located on the shores of picturesque Lake Geneva, Geneva is perfect for those looking for a relaxed environment with a sophisticated, metropolitan vibe.

Basel . Basel sits along the Rhine River, making it a perfect stop on a Rhine River cruise. The city has an old-fashioned feel, with cobblestoned streets and majestic architecture.

Lucerne . Lucerne is located in the German-speaking portion of Switzerland and is known for its historic Old Town and beautiful nearby hiking trails.

Zermatt . Zermatt is known for its location right under the Matterhorn. It is a car-free town, so people get around by walking. If you are planning on hiking in Switzerland, this is a prime destination.

Interlaken . Interlaken is known as a resort town, but is also extremely popular among young backpackers and families. The town also offers some of the best skydiving views in Europe.

Bern . Although lesser-known by tourists, Bern is the capital of Switzerland and a UNESCO World Heritage Site.

Thun . The beautiful village of Thun is an ideal destination for history lovers, with medieval castles dating back to the 12th century.

St. Gallen . With baroque cathedrals and painted oriol windows, St. Gallen is an architecture-lover’s paradise.

Sion . Sion is known for getting the most sun of any town in Switzerland, and is filled with luxurious summer and winter resorts.

Switzerland Souvenirs

A trip to Switzerland isn’t complete without bringing home a carry-on’s worth of chocolate, cheese, and Swiss-designed trinkets. The Swiss take pride in their carved toys and ornaments; tourists can buy the highest quality cuckoo-clocks and music boxes.

Switzerland is filled with street markets selling locally-made souvenirs, and if you’re looking for a luxurious gift for yourself or a loved one, Switzerland has world-class watches and jewelry. While a block of Swiss cheese might not fare well in your suitcase, a ceramic cheese fondue set will serve as a longer-lasting memory.

And while the triangle-shaped Toblerone chocolate is a famous Swiss staple, it is easily available in most countries and online-- visit a local chocolatier shop for a more unique option.

Cultural Activities in Switzerland

Switzerland has many cultural festivals, the most popular being Paleo, a folk festival in Nyon that usually headlines popular artists, and Sechseläuten, a traditional spring festival.

Asides from festivals, there are year-round cultural activities for travelers to enjoy, including museums, art galleries, and cathedrals. Switzerland also boasts 12 UNESCO World Heritage Sites, including Bern Old Town and the Abbey of St. Gall.

Taking the Train in Switzerland

Many tours of Switzerland include a ride on one or more of the country’s trains, renowned for their punctuality and cleanliness, and their large windows which come in very handy to view the spectacular scenery.

Train tours in Switzerland are a classic activity when visiting the country. Trains are much connected with the culture and history of Switzerland and provide the perfect way to learn about the Swiss culture as you wind your way through alpine mountains, meadows, villages, and take in the spectacular scenery all around.

Here are some of the top train journeys you can enjoy in Switzerland:

Bernina Express

This exciting train journey travels through far eastern and southern Switzerland.

You can ride the incredible Bernina Express from the city of Chur (or the resort town of St. Moritz) to the Italian-Swiss town of Poschiavo and continue to Tirano across the border in Italy via the Alps, as you climb and dip repeatedly around steep curves.

If you are afraid of heights, you may want to consider another Switzerland train trip. No less than 196 bridges are crossed along your journey on the Bernina Express.

Glacier Express

Equally scenic is the Glacier Express, which runs from St. Moritz through the Alps to Zermatt, in the shadow of the Matterhorn. The full trip, which takes seven hours, crosses nearly 300 bridges, runs through nearly 100 tunnels, climbs mountains (up to 6,600 feet at Oberalp Pass ) and snakes through deep gorges.

This is one of the longest routes for Switzerland’s scenic train journeys. While it’s possible to pick it up at one of the many stops along the way, many travelers opt to take the entire route.

Chocolate Train

Dive into Switzerland’s extensive chocolate cultural history aboard this delectable journey. Don’t be dissuaded if you’re not interested in chocolate. On this train trip, you will also sample cheese - Switzerland’s other famous food group.

You’ll begin with a tour of Gruyere Castle (not a castle of cheese, sadly). After which enjoy a leisurely lunch in town. Which will include the famous namesake, Gruyere.

Continue on to the Cailler-Nestle chocolate factory in Broc. This is a very popular Switzerland tour activity, and though it may be a bit crowded and tourists, it’s a fun afternoon nonetheless.

Jungfraujoch Cog Railway

The most amazing train may be the Jungfraujoch, a cog railway that climbs up the adjacent alpine peaks of the Eiger, Jungfrau and Monch to Europe’s highest train station at more than 11,000 feet, a remarkable feat of engineering completed a century ago. From the top, you have panoramic views of the valleys and villages below – and can play in the snow if you wish.

Switzerland's Resort Areas

St. Moritz and Zermatt – which make up the two ends of the Glacier Express route -- are probably the best known. Both are in German-speaking Switzerland and both feature excellent alpine skiing. But they’re also very pleasant places to stay in the summer, offering exceptional hiking in cooler temperatures than most places in Europe at that time.

If you really want to experience alpine climbing, however, sign up for a guided expedition up the Matterhorn, whose spiral shape forms the iconic image of Disneyland. This is no Disney adventure, though – while a few thousand people make the climb every year, some never come back. It’s not for novices.

But fear not. If you want to see the famous mountain, you don’t need to sign up for a life threatening mountaineering tour. The Matterhorn is a classic Swiss natural landmark, also visible from safe distances. Your tour guide will point out the best viewing opportunities!

Another popular resort area is Lake Constance in northwest Switzerland, which also shares borders with Germany and Austria . A cycling path circles the entire lake.

One often overlooked resort area is the Interlaken-Wengen-Grindelwald region , which lies in the shadow of the Eiger, Jungfrau and Monch. The area features superb hiking, and scenery, including dozens of little trains climbing the hills to a variety of villages. The three mentioned here are all considered to be in the top ten of scenic Swiss villages.

Hiking and Walking Tours in Switzerland

Walking tours of Switzerland are extremely popular. Classic alpine hills provide the quintessential Swiss experience, as you explore small towns nestled high in the mountains. These can be accessed by strenuous hikes, but one of the unique things about Switzerland is that they don’t have to be.

Attractive to many older travelers, Switzerland’s alpine meadows aren’t a pipe dream! Easily accessible by the many cog railways, it’s possible to breathe that mountain air without over exertion. Many walking tours will stay in luxury mountain lodges, allowing you plenty of time to rest up for another full day outside among the wildflowers.

If you are a hiker, this can be an exhilarating way to experience Switzerland's famous alps. Make sure you’re up for the challenge! The mountains are no joke, even though Captain Von Trapp made it look easy. Most hiking tours through the alps don’t involve camping and you will stay in moderate by comfortable lodges and hotels along the way.

Some of the most popular hikes in Switzerland include:

Champlönch Children's Trail : As the name might suggest, this is one of the simplest trails in Switzerland, but no less beautiful than some of the more demanding hikes. A great option for families with young children, as you walk among the meadows and enjoy the alpine air of this 100 year old nature reserve. You’ll end at Hotel Il Fuorn, which is no longer a functioning hotel, but serves as a base to rest before heading back to the train.

Mont Blanc : a great through-hike experience for first timers. You’ll stay in classic mountain villas and lodges along the way, enjoying delicious local cuisine, and experiencing the hospitality of small Alpine villages. The mountain views are impeccable - some of the best in all of Switzerland. A tour of Mont Blanc can be experienced in many ways, from luxury to hard core trekking, but trekking is appealing to many for the accomplishment of crossing three international borders on foot.

Read more about The Tour du Mont Blanc and the top 10 treks in the world >>

The Eiger Trail : within view of three mountain peaks that sound like they should be characters in a classic fairy tale, “ the Ogre, Monk and Maiden” (Eiger, Mönch and Jungfrau), the Eiger is a challenging by manageable trail. Roughly two hours long, among spectacular views of the Jungfrau region, the trail is accessed by one of Switzerland’s renowned mountain trails. More serious climbers often brave the mountainsides in this area, and hikers along the 3.7 mile Eiger trail can sometimes see them - bring binoculars!

Aletsch Trail : for sweeping glacier views of Great Aletsch Glacier, this hike is long, but moderate - most relatively physically fit travelers will be able to enjoy the 7 mile trail. Feel like you’re in Lord of the Rings as you follow rock steps, and snow capped peaks flank you on either side. Along the way you’ll reach beautiful Lake Märjelen where an apple tart from Restaurant Gletscherstube is not to be passed up.

Find more hiking and walking tours >>

Outdoor Activities in Switzerland (besides hiking)

Many people travel to Switzerland for its expansive hiking trails, but there are many other outdoor activities to try out. Switzerland boasts some of the world’s best ski resorts, as well as many cross-country and snowshoeing trails.

A top winter destination in Switzerland is Zermatt, where skiers can ski under the Matterhorn and stay at one of the town’s luxury resorts. Summer travelers can kayak, paddleboard, and swim on turquoise alpine lakes, the largest and most popular being Lake Geneva, Lake Zurich, and Lake Brienz (Interlaken). For bird’s-eye views, try skydiving or paragliding.

Food in Switzerland

What can you expect from the cuisine of Switzerland? Well, for starters, what you’re probably thinking right now is actually true. Chocolate and Swiss cheese will feature prominently on your Switzerland tour! But there are many other things as well to try.

Swiss food features a lot of cheese, potatoes, and has a rustic homey vibe. Most dishes have a regional variety, though are popular throughout the country.

Here are some of the top can’t miss foods to try in Switzerland:

1. Fondue - Another classic Switzerland food experience. This delicious and gooey meal has many modern iterations in today’s food scene, but the traditional way to serve and make it is still the most prominent in Switzerland. This involves melted swiss cheese and chunks of thick country bread. Usually enjoyed in the wintertime, it has snuck into the other seasons as well to the delight of travelers who visit year round.

2. Raclette - Sometimes confused to be synonymous with Fondue, Raclette is in fact it’s own specific dish. Though it does involve melted cheese. Raclette is a hard round cheese that, when melted becomes a soft piece of heaven. The old way to prepare it involved a hot stone - today the process is similar but a bit more advanced than stone. Special Raclette pots are used to heat the cheese which is then scraped off into a bowl or onto individual plates. Various meats and vegetables are then dipped into the delicious, strong tasting cheese.

3. Chocolate - The Swiss are among the largest consumers of chocolate in the entire world, eating on average 23 pounds per person per year. So if you really want the local experience in Switzerland, you will have to sample some chocolate. What a shame! Luckily there are many ways to eat chocolate in Switzerland while also learning about chocolate history with the country or just having a lot of fun, including chocolate festivals, chocolate museums, and chocolate tours.

The Swiss legacy with chocolate began in the 1800s when this most delectable of products from South America began arriving in Europe. Swiss innovators added milk to the mixture, turning the traditionally dark flavors of cacao sweeter and more welcoming to European palates. Many recognizable names from this era come to the surface: Tobler and Nestle among them.

4. Leckerli - A Christmas tradition in Switzerland, these gingerbread biscuits have German roots, but have been enjoyed throughout Switzerland for centuries. If you’re touring Switzerland at other times of the year, you may still find Leckerli, but it is most commonly enjoyed during winter. A delicious treat to have strolling through idyllic Christmas markets with twinkling lights and softly falling snow.

5. Rosti - A classic potato pancake, made from shaved raw potato which is then fried. This dish is served all over the country - though it began as a traditional farmer breakfast in the Bern region. Often regions around Switzerland will add their own touches to Rosti, such as onions or cheese. You’re sure to encounter many versions of Rosti on your Switzerland tour!

Switzerland's 4 National Languages

Sharing borders with Italy, France, Germany, and Austria, it should come as no surprise that there are 4 national languages in Switzerland.

German is the most widely spoken, followed by French, then Italian. The fourth most popular language spoken is called Romansh. This is the official language of a small Swiss canton in the far eastern part of the country. It was established as a national language in 1938.

Approximately 70,000 people speak this language, which is primarily influenced by German, and descended from the latin of the Roman Empire.

Weather in Switzerland

Not counting the Alpine regions, Switzerland has a relatively mild climate. It gets quite cold in the wintertime and summers are generally temperate with the highest temperatures hovering in the mid 90s. Summer can be rainy too however, with temperatures in the high 50s (F).

The Alps is an entirely different story. Mountain weather is notoriously difficult to predict. In the eastern Swiss Alpine regions, you can expect cold but very dry conditions. The Western Alps tend to get more precipitation. The best time to visit the Swiss Alps for hiking is between June and September.

Some of the mildest weather in the Alps occurs between April and June and in the Fall. If you’re visiting Switzerland during the months of August and September and October, this is a great time to visit wineries during harvest.

Trip Reviews

Trusted Customer

Splendors of Italy

Covered all the amazing spots

We saw amazing places. We wish we weren’t always so rushed, especially at ...

A very thorough visit to highlight areas of the country. A fast paced trip with quite a bit of walking over uneven surfaces as well as stairs to climb. Italy does n...

The hotels were modest meaning small evelvators, some of the rooms had smells that took getting used to, and some of the rooms did not have adequate air conditioning...

See all Switzerland reviews

Related Trips & Tours

Switzerland tours faq.

1. Does Travelstride have all the tour operators?

2. How does the Member Savings program save me money?

3. Can I trust the tour operator and trip reviews on Travelstride?

4. What does ‘Stride Preferred’ mean?

Interlaken Top Tours

Discover the best of Interlaken and the Jungfrau region on a unique, exclusive private minivan tour Mountains – lakes – adventure

Private sightseeing tours

Private sightseeing day tours from all Swiss cities with your personal Swiss driver & guide Zürich – Lucerne – Geneva

Tailor made tours

Custom tailored unique tours. Tour creation, organisation, guiding is out of one hand Family – Honeymoon – Luxury

VIP Train Tours

VIP panorama train package tours including 1st class train and accommodation in selected 4*/5* hotels Lucerne-Interlaken-Zermatt

Escorted tours of Switzerland with your private guide Family – Honeymoon – Luxury

Exclusive Guiding service

Exclusive, unique, authentic guiding. Sibylle or Stefan presents you the best of Switzerland unique – authentic – local

We offer unique Luxury travels, private sightseeing day tours & escorted tours of Switzerland

Are you looking for a custom tailored tour with your personal local swiss guide, we’re specialised in exclusive tailor-made private day tours as well as in escorted tours of switzerland and unique private guiding..

Experience real Switzerland on a tailor-made private tour or escorted roundtrip with your local guide. Above all your personal local Swss guide creates you a unique, authentic, unforgettable Swiss vacation. Explore the beauty of Switzerland, hidden nature places, unforgettable sceneries and spectacular views. First of all Switzerland is spot for vacationers, nature lovers, honeymooners and adventure freaks.

Second, Switzerland is one of Europe’s most appealing & favorite destinations for travelers. It is home to stunning mountains & beautiful lakes, as well as charming cities and incredible outdoor activities. Discover the land of Heidi, Moreover, we invite you to local Swiss farmer’s house’s and watch how real Swiss alpine cheese is made. Last but not least discover the secret of the famous Swiss chocolate.

My name is Sibylle, i am the owner of Pure Switzerland – Tours & Guiding. I am your Tour Designer, Tour Leader and driver&guide (English, French, German, Spanish, Arabic) .Together with my partner, we are specially focusing our efforts to show you real Switzerland and its landscapes, mountains & hidden places combined with history and traditions. All guided by a local multilingual Swiss guide who is also your personal tour assistant and Swiss friend. Therefore, book your unique Swiss vacation with us and discover pure Switzerland.

Your tour will be accompanied by Sib ylle or her partners as expert Swiss Guide having great knowledge of the areas, the Swiss culture, customs, traditions and a lot more. As well as that you can also book Sibylle as your personal tour leader and assistant for a stressfree, exclusive holiday.

On your journey you’ll travel not only by private car but also with old nostalgic trains and enjoy a boat trip on one of the thousands of lakes, or for instance drive over stunning mountain passes. During your tailor-made private tour, You’ll visit old traditional cheese dair y, beautiful handicraft businesses or make your own personal Swiss knife and and even so get in touch with local Swiss people.

In addition, we offer not only the Best of Switzerland private Tours, Escorted Tours of Switzerland and any other special Tour like photo shootings or adventure holidays, kids friendly or finally a digital detox time in Switzerland. Furthermore we also offer unique train packages operated by our selected partner.

In conclusion, the local guides of Pure Switzerland, Sibylle or her team of selected Swiss guides, show you the unique, authentic and local Switzerland private Sightseeing Tours and besides off the main tourist track we present you the treasures of Switzerland.

Testimonials

Goh yoh seng, singapore, dezember 16.

I had an excellent tour with my 3 generation family around Switzerland recently, 27 Nov – 8 Dec 2017. Sibi was very attentive to the needs of my family and she was very passionate towards ensuring the trip is comfortable especially for my parents who have mobility difficulties. She had made the trip extremely fun for the children and they miss her after the trip.

Ameena, Dar el salam, Tansania / July 17

Wonderful wonderful day with Sibi..

Literally the best day of our 10 day trip to Switzerland… Sibi is an excellent guide, we had an amazing time with her. We did the lake and gorge tour with her.. It was like a dream come true. She was forever so enthusiastic the whole time and so eager to show us the best of this beautiful town.

The whole tour was very well arranged by her. Highly highly recommend and wouldn’t mind another tour with her if i was to visit Switzerland again.. Thanks sibi…

Rihlat Europe, Januar 2017

Amazing Company, great tours! Can really recommend!!

JayDei, Tiruppur, India October 16

AwesomeSwiss! – Thanks to PureSwiss!!

We were two families with kids and spent 5 fabulous days in Switzerland in early May. Thanks to our guide Sibylle for taking so much care of us, esp. the kids. The highlight of the trip was exploring the non-tourist/ hidden-treasures of Switzerland. Kids had a blast snow-sledging/ Zip-trekking with Sibylle… Swiss memories to cherish for life-time! Our group was glad that we didn’t choose any other “tourist” company. Truly Unique & Authentic! Highly recommended for families with Kids/ Teens.

Min, Kuala Lumpur, Malaysia, October 16

Seeing the best of Interlaken with Sibi

We had an afternoon tour with our guide Sibi who is bubbly and knowledgeable. Sibi came to our hotel to pick us up in a 7-seater MPV which we think it is the best way to travel around Interlaken. We had a quick discussion with Sibi on the itinerary and Sibi offered to bring us around Lake Brienz and the village nearby as well since it would be our last day in Interlaken and we haven’t been there. As we are a family of three Sibi tried her best to let each of us to have something that we like – dad loves waterfall so we went to Giessbach Waterfall; mom loves apple tree and we stopped by a Swiss farm to take picture in front of a real apple tree; while myself, prefers a traditional Swiss house and we left for a village near Lake Brienz. The best part of the tour is Sibi, not only being a tour guide but also play her role as a host of Interlaken and the nearby places. Her passion in making sure all of us feel comfortable and get to know about the culture, people and the place is second to none. Interlaken become so much more meaningful and excited with Sibi around. Thanks again very much to Sibi, for a wonderful experience in Interlaken.

La Hay Khu, Singapore, September 16

Fantastic!!!!!

The tour was great. Our guide Sibylle was extremely helpful. She made us feel at home and the normal Swiss life. I’d recommend Sibi (Sibylle) if you were to come to visit Switzerland. We have covered almost all the iconic places and even small alleys although our trip was just a short period. Sibi is the best!!! We really enjoyed and had a great experience.

Donna, Springfield Missouri, / August 18

Interlaken and area tour

We had a group of 23. Sybille does an OUTSTANDING job! Very knowledgeable, and she shared all the stories of her hometown. We fell in love with this beautiful area. I would highly recommend her and her company!

Ann, Singapore, / July 18

PURE SWITZERLAND…PERFECT for Swiss travel!!!!!

Sibylle is knowledgeable , kind, caring, and fun. Sibi catered to our every wish on our amazing 8 day journey. She picked us up at Zurich airport , bringing us to Grindelwald, Gruyeres, Montreux , Zermatt and all the way to Lake Como.We have traveled on deluxe tours but, experiencing it with this Swiss gem is incomparable. She customized our journey with many suggestions and delivered us, off and on the beaten path. Travelers cannot experience personalized itineraries on

bus tours. The Mercedes van was well stocked with goodies and kept immaculate daily. Sibi truly made our trip so memorable. Can’t wait to return!!!!!

Pankti, India, October 14

Thank you fort he fabulous time we had with you.

Abdullah, Qatar, August 14

I am Mr. Abdulla & my family (six ladies) from Qatar, we acknowledge the excellent services & times that Mrs. Sibylle offered, touring in her van from 1st- 7th Aug. 2014 from Geneva, Interlaken, Luzern to Zürich, where we spent a wonderful time with her. We can happily recommend her 100% as a tourist guide in Switzerland.

Best Regards,

Sue, Burbank, California, USA / April 18

Sibi Sibi Sibi…The best tour guide in Switzerland!

Hi! We spent 7 fabulous days with Sibi. She’s super easy-going and just wants to please AND give suggestions along the way. I liked when she’d occasionally drop us off at a site and say, “OK, I’ll meet you later in 1 or 2 hours. We were free to wander 🙂 Then she’d pick us up and we’d go to another wonderful place… maybe she’d stay with us this time to give us the insights of the area. She drove us all over Switzerland, from Zurich to Interlaken, to Geneva and even across the Italian Alps to Milan! We always felt safe and in capable hands. We took the train up to Jungfrau and spent the day at the top of the mountain… don’t miss this! She took us to a young couple’s home where the cow bells were ringing in the hills and they made cheese in their barn. Sibi always does her homework and has everything you want to do planned out so things run smoothly. If you don’t know what you want to do, she’s spontaneous and makes great suggestions. Sibi is funny and will share her insights into the Swiss history and culture. I hightly recommend Sibi and Pure Switzerland. We’ll be going back to do the things we didn’t get a chance to do, with Sibi as our guide, of course!

Francine, Springfield, USA / September 18

Sibylle was our guide to tour the towns around Interlaken. She arranged warm Swiss quiches for our lunch in the park by the lake. A couple of days later she took us on a private tour of a cheesemaking factory in Gruyere followed by the Maison Cailler chocolate factory– and in between, she treated us to dessert and drinks at the H. R. Giger “Alien Bar” in Gruyere. Thank you, Sibylle, for your attentive guiding.

Francis, Minneapolis, Minnesota, USA / Oktober 18

Purely Amazing!!!

On a recent trip to Switzerland our travel agent arranged a two-day tour with Pure Switzerland and our guide was Sibylle. Not only was she professional and knowledgeable, she made our tours amazing. She was the perfect match for our group, and no detail was overlooked! If you have the opportunity to tour this beautiful country please request Pure Switzerland and Sibi. You will not be disappointed!

Gita, Mumbai, India / April 18

Sibi is the best!!!

I don’t know where to start but Sibi was the most caring and kind person I have known. She took me and my family where ever we wanted to go and stop.

John & Barbara, USA, June 17

My husband and I were excited to spend our vacation in Switzerland during the summer of 2017 since we heard much about the beautiful mountains, lakes, villages and the famous Alps. With limited time and transportation we needed a tour guide who could provide the personal attention to our needs recommending the truly best places.

Our trip became special at Interlachen when we connected with Sibylle who made the difference between a good tour guide and a great tour guide!

Sibylle gave us a warm and enthusiastic welcome. Her skills were evident from the beginning in her communication (English speaking), flexibility and passion for her work. She demonstrated her true insider knowledge of the outdoor activities and attractions giving depth to the historical and cultural background of each. As a result, we experienced the

excitement and beauty of the Swiss Skyline, Brienz waterfalls, alpine meadows and legendary Grandhotel Giessbach. After a full day of touring, Sibylle found us the Grimsel Hospiz with a stunning view and great hospitality. She also helped us navigate our next trip to Milan by rail which would have been challenging without her direction. I highly recommend Sibylle to any traveler for an outstanding and memorable Swiss experience.

Priya, Texas, USA , June 17

Perfect trip thanks to Sibi!!!!

We got visit many areas of Switzerland thanks to Sibi’s knowledge and appreciation for her country!!! She catered to all of your needs such as our interests and our physical needs. She made sure to make all of our desires come to life such as stopping to take pictures with cows in the countryside. She is the sweetest, most caring, and most enthusiastic person!!! She has a great love for the wellness and beauty of Switzerland which is just amazing! Traveling with her was the experience of a lifetime!

Thanks for visiting nordicvisitor.com! For the very best browsing experience on our website, we urge you to upgrade to the most recent version of your browser . Some of our site features may not function properly on older versions.

- Search Suggested Results View All Results

- EUR (€)

- GBP (£)

- Self Drive i

- All Types & Themes

- All Switzerland Tours

- Why book with us i

- Booking Terms i

- Sustainability Policy i

- Scandinavia

- Switzerland

- United Kingdom

- Manage Booking

- Privacy policy

Iceland Bíldshöfði 20 110 Reykjavík +354 578 20 80 View Map

Sweden Scotland View Details

Your Switzerland Travel Agency

Picture yourself gazing up at towering snow-capped peaks, strolling through Alpine meadows, and enjoying tranquil evenings beside Lake Geneva. You could do just that by heading to Nordic Visitor’s brand new destination, Switzerland. You’ll get 24/7 support during your trip and a dedicated travel consultant to arrange your accommodation, local transport, and more.

Ways to Travel in Switzerland

Choose the travel style that works for you and explore Switzerland your way.

Switzerland Self-Drive Tours

Experience the beauty of Switzerland on an unforgettable road trip.

Multi-Country Self-Drive Tours

Discover the highlights of Switzerland, Austria, Germany and beyond.

Switzerland Tours

Make those Swiss chocolate-box views come to life on a self-drive trip, complete with car rental and handpicked accommodation.

Express Switzerland

Switzerland road trip, classic switzerland, switzerland at leisure, featured tour.

Watch this space for recommended packages.

COMPLETE SWITZERLAND

Get in touch with one of our local travel experts.

Whatever your needs, we are here to help. If you have any questions about our packages or services, please do not hesitate to contact us.

Switzerland Travel Experts

You can trust that our travel experts know how to plan the ultimate Swiss getaway. They’ve travelled the routes, walked the trails, and visited the attractions that you’re about to see for yourself. Plus, when you’re travelling, you’ll benefit from our 24/7 helpline, ensuring a friendly local is always on-hand for you.

Quick Facts

About Nordic Visitor Tours

Nordic Visitor has been creating amazing travel experiences for customers across Northern Europe since 2002. We now have multi country tours and regional offices, but still retain our core values of providing great value packages and amazing service, before, during and after your trip. Reasons to choose us include:

- Tailor-made itinerary: you deserve to have the vacation of a lifetime, so trust our tour operators to grant your travel wishes.

- Quality checked accommodation: Everywhere you stay is approved by a local specialist.

- Travel guide: your journey will be extra special with our team's insider travel tips and hidden gem attractions.

- 24/7 helpline: for peace of mind, there’s always a travel consultant on the other end of our 24/7 helpline.

Get Social With Us

Follow our adventures and share your own with us.

Sign up for our newsletter

Get in touch if you have a question about one of these Switzerland tours, or if you’re ready to start planning your trip. Whatever you want to know about planning a Swiss adventure, contact us and we’ll be happy to help.

Our main phone number is +354 578 20 80

How about a live chat with one of our local travel experts

Whether you have a single question or a special request, we're here for you.

Explore the world with tourHQ

- Destinations

- I am a Guide

- I am a Traveller

- Online Experiences

- Currency (USD)

Switzerland

Come and explore the sheer faces of the Eiger, the regal town of Lucerne, the Jungfrau ski fields, the shimmering Geneva Lake and more with help from a local Swiss guide from tourHQ.

Search Cities in Switzerland

Switzerland Tour Guides

Artur Górniewski

Hello Dear TourHQ Friends, I am a passionate traveller myself and I am glad if I can help you out ...

Ilknur Tirkaz

Dear Travellers, I am Ilknur, a licensed tour guide in Bern, Switzerland. I have ...

I have a bachelor`s degree in Sustainable tourism and also tourist guide professional license. I ...

Jiri Slachta

Meet me, Jiri, a seasoned tourism professional with a passion for exploration and sharing the ...

Celia Boumpas

Join me on a journey through time and nature, where every corner holds a story and every step is an ...

Mandikova Leona

I am friendly down to earth person with warm and wecoming smile. My passion is firewalking but ...

Mhd Towfik Al khatib

Thank you for your interest in my services , I am an architect , I live in Switzerland since ...

Emilie Bissardon

For more than 20 years, I've been guiding people from all over the world in Switzerland, France and ...

Helder Ferreira

I have more than 20 years of working experience as a Freelance Travel Escort ...

Levy Dominique

je suis guide en ville de Fribourg.Je fais visiter la ville à des groupes ou de manière ...

Catharina Oostindier

I am Catharina, and I have always been passionate about travelling. I studied Italian language and ...

Nadja Bayard

It was 2003 that I started working as an interpreter and a tour guide in St. Petersburg after ...

Victor Traill

Hi, I am a Tasmanian-born guide now living in Lausanne, Switzerland. Having studied Adventure ...

Pascal Zeller

I am lucky to live near Interlaken Switzerland, at the foot of the Eiger north face, an area ...

Stephen Hadik

Anna Tsogolakyan

The birthplace of chocolate and cuckooing clocks, political liberalism and winter sports, the nation of Switzerland is crowned by the chiselled Matterhorn and endowed with the very roof of Western Europe’s most dramatic Alpine ranges, making it one of the world’s most enticing travel destinations to boot. Today, the inner mountain ranges buzz with the cream of the continent’s jet set high society. They come to sip champagne in the world-famous après bars of the Graubunden and the Berner Oberland, while clusters of other winter sports enthusiasts flock here for a taste of Europe’s best kept slopes and mountain towns. In the summer, the Alpine valleys bloom, opening up streams of meandering trails and wondrous vistas of glacier-topped peaks. Some come to wander the looping circuits that wend around the base of the Eiger, while few dare to adorn mountain gear for the dangerous trek up its craggy face. But, as every Switzerland tourist guide will tell you, it’s not all about mountains and peaks in this landlocked corner of Europe. There are cities too; metropolitan melting pots of grand banks and super-chic café bars that vivify late into the night.

Tell us your destination, date, and group size.

Our team of travel experts and guides will design a tailored itinerary just for you., enjoy your trip with peace of mind knowing everything is taken care of..

Say Goodbye to Travel Stress

Choose Currency Close modal

- USD US, dollar

- GBP British Pounds

Cookie icon We use cookies!

We, and third parties, use cookies for technical and analytical purposes, for marketing purposes and for integration with social media. For more information, refer to our Privacy Policy and Terms of Consent.

By clicking on 'I agree', you consent to the use of these cookies.

Switzerland

Travel guide.

- Things to Do

- Getting Around

- Escorted Tours & Independent Package Tours

- Calendar of Events

- Tips on Accommodations

- Sustainable Travel & Ecotourism

- Getting There

- Health & Safety

- Entry Requirements & Customs

- Tips for Families

- Tips for Gay and Lesbian Travelers

- Tips for Senior Travelers

- Tips for Travelers with Disabilities

- Tips for Vegetarian Travelers

- Staying Connected

- Regions in Brief

- Active Pursuits

- Suggested Itineraries

Escorted Tours and Independent Package Tours in Switzerland

Escorted tours are structured group tours, with a group leader. The price usually includes everything: airfare, hotels, meals, tours, admission costs, and local transportation.

There are many escorted-tour companies to choose from, each offering transportation to and within Switzerland, prearranged hotel space, and such extras as bilingual tour guides and lectures.

Tour Operators

Organizations that offer both escorted and package tours are Abercrombie & Kent , Trafalgar Tours , Globus & Cosmos , Grand Circle Travel , and Connection Tours .

For river cruises (also barge tours), a most reliable agency for both Switzerland and Germany is Viking River Cruises .

Be it rafting, canoeing, sea kayaking, sailing, biking, hiking, paragliding, or horse-and-wagon trips, Eurotrek has a tour for you. All ages, tastes, and levels of fitness participate in these tours, from absolute beginners to experienced athletes. The outfit uses skilled travel guides, instructors, skippers, and coach drivers. Rafting adventures, for example, are arranged in the Bernese Oberland or on the Lütschine, the wild river at the foot of the Eiger and Jungfrau. Sailing trips are arranged on both Lake Thun and Lake Maggiore, and horse-and-wagon treks explore both the Emmental and the Jura in covered wagons. You can bungee jump in the alpine regions around Davos, or book a 3-day bike tour through the Ticino.

Note : This information was accurate when it was published, but can change without notice. Please be sure to confirm all rates and details directly with the companies in question before planning your trip.

- All Regions

- Australia & South Pacific

- Caribbean & Atlantic

- Central & South America

- Middle East & Africa

- North America

- Washington, D.C.

- San Francisco

- New York City

- Los Angeles

- Arts & Culture

- Beach & Water Sports

- Local Experiences

- Food & Drink

- Outdoor & Adventure

- National Parks

- Winter Sports

- Travelers with Disabilities

- Family & Kids

- All Slideshows

- Hotel Deals

- Car Rentals

- Flight Alerts

- Credit Cards & Loyalty Points

- Cruise News

- Entry Requirements & Customs

- Car, Bus, Rail News

- Money & Fees

- Health, Insurance, Security

- Packing & Luggage

- -Arthur Frommer Online

- -Passportable

- Road Trip Guides

- Alaska Made Easy

- Great Vacation Ideas in the U.S.A.

- Best of the Caribbean

- Best of Mexico

- Cruise Inspiration

- Best Places to Go 2024

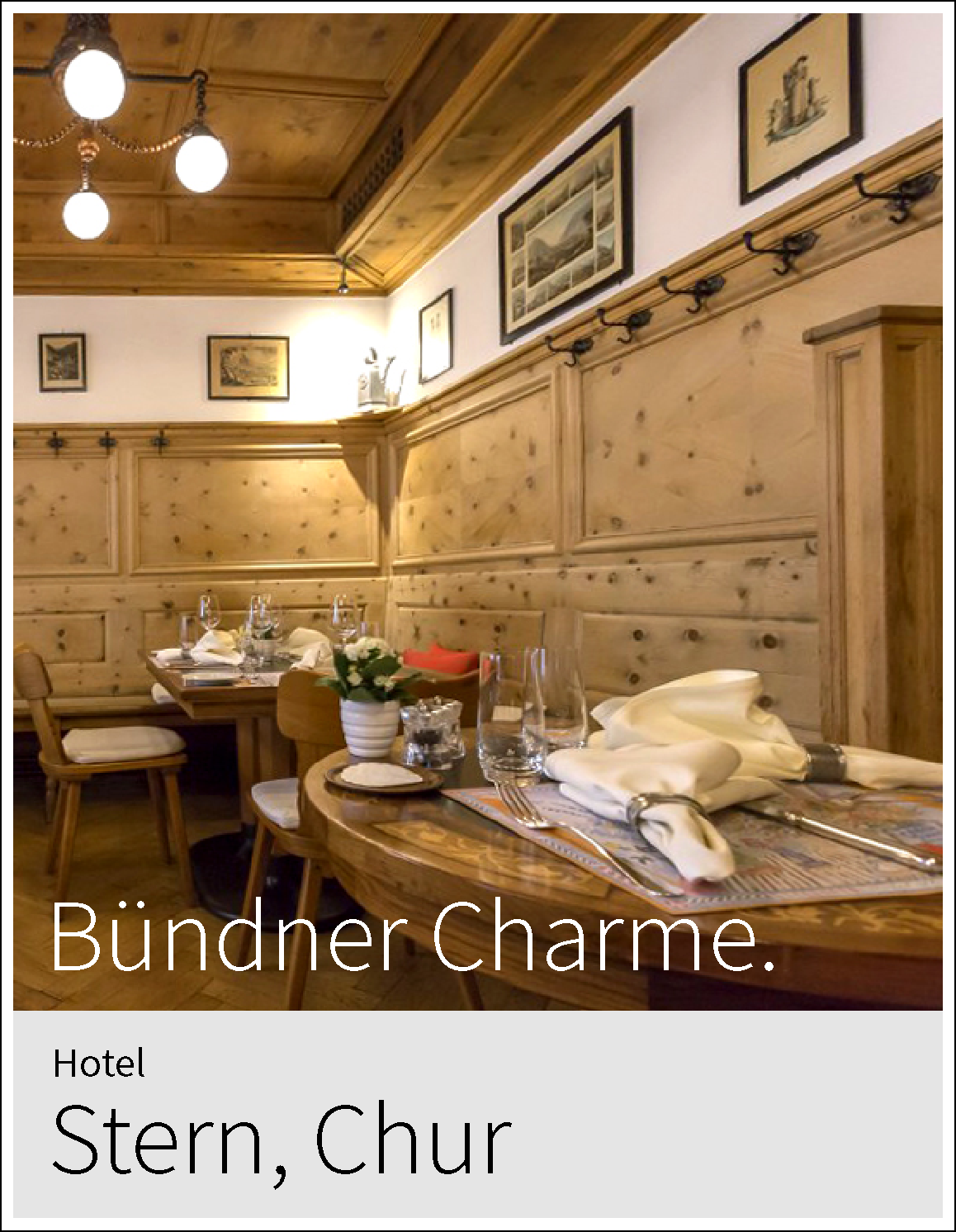

Why Magic – How we add value

Magic Switzerland is a full service Switzerland destination specialist and Tour Operator. The company was founded in 2000 and today we are one of the premier travel companies specializing in Switzerland and promoting Swiss tourism.

Our specialty are self-guided, custom packages for individuals and groups.

Our portfolio of services also includes guided group tours, add-on packages to European vacations and river cruises, self-guided standard train tours , and Switzerland destination related consulting services.

Our Travel Consultants prepare extraordinary travel experiences for individuals and groups with an emphasis on superior service. We are Switzerland experts and have the tourism know-how to advise our clients which is our passion. Our goal is for our clients to have an unforgettable vacation experience which is why we come to work.

There is no make-up for a vacation gone wrong!

Let’s talk about your planned Switzerland vacation. We know Switzerland as our own backyard and will make sure you visit the Swiss places which are relevant to you. Of course, you could book hotels and other services online, but the choices at an unknown destination can be overwhelming. We make sure all will go well and you will have a memorable experience.

Here are a few of the many ways we make sure your dream vacation becomes reality:

Destination guidance and setting an itinerary We know Switzerland inside out and have stayed in the various destinations ourselves. We don’t depend on online reviews but relay first-hand information to you. We prepare a detailed itinerary for you and plan the most efficient ways of transportation including scenic trains .

Insight into Switzerland We know what places to see in Switzerland - places which are not overbooked or are about to become the next big thing. We have resources and local contacts at our fingertips, we provide you with insider information. Even with an overwhelming amount of information to be found online there is still so much left unknown, especially if you want to get off the beaten path.

Better customer service and advocating on behalf of you We are with you from the minute you contact us until you return home. We advocate for you and assist in case an unforeseen event happens. If you miss your flight we take care of changing your reservations in Switzerland. When there is a problem we will intervene on your behalf. You might directly contact your Magic Switzerland Travel Consultant, we are real people and work things out.

Saving you money and getting you perks We don’t promise to save you money, but that is not to say we don’t hold costs down. We know the discounts and promotions and the best days and ways to travel. We save you hours of research for your unforgettable trip - once we know what you are looking for, we can put together your perfect Switzerland vacation package . We have long established relationships with the best Swiss hotels and sometimes can get you free room upgrades, free train station pick up and other perks.

Offering extended payment plans and budgeting Magic Switzerland only requires a deposit at the time of booking. You can elect to pay the balance in one lump sum or make payments in installments as your trip departure date nears. We map out exactly how much your trip will cost you so there won’t be any surprises.

Knowing the right insurance We recommend SquareMouth for travel insurance - this online tool lets you compare more than 100 products from various providers and you can select the policy which fits your circumstances best.

In short, if you have not contacted us yet, now is the time to do so in order to save you time and hassles. We will plan a custom itinerary for your Switzerland vacation!

Company Details

Contact information.

Magic Travel Services GmbH Kammermattweg 4 4107 Ettingen Switzerland

Phone: +41 061 588 01 58

E-Mail: admin magictravelservices ch

Terms and Conditions: Policy

Magic Switzerland

Founded in 2000

Languages: English, German, Spanish, Italian, Indonesian

How we add value

Travel Consultants Booking Process Tell us about yourself

Consulting Services

Switzerland Tips Travel Agents

What to do in Switzerland Best places to visit Car-free destinations Swiss Alps Transportation in Switzerland Swiss Rail Passes Scenic Trains Switzerland sample Itineraries Vacation Planner Grand Tour of Switzerland

Swiss Voyages

Switzerland Destination Management Company

Explore Switzerland

See what people are traveling for, in switzerland.

Swiss Rail Packages

Take a Grand Tour of Switzerland in Rail Our rail tour packages combines most breathtaking routes in the Swiss Alps. Book your Swiss Rail Packages for 2 Nights to 9 Nights, enjoy splendid inclusions of travel by rail, boat,postal-coaches and...

Escorted Coach Tours

Take a Grand Alpine Tour of Switzerland in an Escorted Coach Tour Our fixed departure coach tours combine most breathtaking routes in the Swiss Alps. Book your Escorted Coach Tours for 2 Nights to 9 Nights, enjoy splendid inclusions of...

Private Van Tours

Itinerary Day 1: Arrival Zurich/Geneva Airport/ Swiss Border. Pick-up by a Chauffeur driven private Van/Car and drive to Luzern through some of the stunning setting of Lakes and mountains and exciting old & modern architecture. After hotel Check in proceed to...

The Best of Switzerland

Checkout Most Popular Holiday Packages for EUROPE & SWITZERLAND !!

Best of Switzerland

Rail adventure – r804, lakes of switzerland – r803, grand train tour of switzerland.

Any questions related to Swiss Voyages?

Whatsapp Us

🟢 we are online

WhatsApp us

Start your journey with us.

bucher incoming

Your agency for customized individual & group travel.

bucher events

Your full-service agency for incentives & conventions.

Your reliable partner for bus & limousine service.

bucher reisen

Your travel agency for vacation & businesstravel.

Bucher Travel Inc.

We are your leading full-service agency in Switzerland for any typ of travel services. We design tailor-made luxury itineraries, create unique incentives and events, coordinate professional transfers as well as global travel experiences. Our more than 65 experienced employees will be happy to help you.

We are focusing on sustainability with a new photovoltaic system

We have taken a significant step towards sustainability - with our new photovoltaic system, we generate clean energy for a greener future. Learn more in our post.

Our locations

Bucher Travel Inc. Pilatusstrasse 27 6036 Dierikon +41 41 418 55 55 [email protected]

Alphubel Limousine & Taxi Service Kantonsstrasse 153 3929 Täsch/Zermatt +41 27 967 15 50 [email protected]

Bucher Reisen Pilatusstrasse 32 6003 Lucerne +41 41 418 55 22 [email protected]

Years in business

Motivated employees

Tailor-made programs per year

10'000+

Transfers per year

Our memberships

We are members of the organizations listed below. We believe in networking and therefore regularly participate in worldwide trade shows. Ask us about our trade show participations to make sure we already have the opportunity to meet in your country.

@bucher_travel

“I wanted to reach out to share what a fantastic experience it was working with Bucher on our Switzerland incentive trip this October! Melanie was an absolute pleasure to work with, helping us put together the perfect experience for our guests. With almost 150 guests on the trip, the diverse tour and activity options provided helped us cater to all of our guest's interests. The organization of your team was also a big stand out as it was many of our guest's first time traveling abroad and a lot of guidance was vital to make it a smooth and successful trip. Thank you!"