Slips, Trips, and Falls toolbox talk

A simple, 5 minute outline of what to cover in a toolbox talk on Slips, Trips, and Falls.

Download a Slips, Trips, and Falls toolbox talk pdf

Slips, trips and falls are a common reason for many of the injuries in workplaces. They can cause minor injuries but can also lead to serious, long-term injuries. Many slip, trips and falls are avoidable and there are usually easy solutions a workplace can apply to control the risk, either by eliminating or minimising it. It could be as simple as cleaning up a spillage straight away, or moving a cord off a walkway which can prevent injuries from occurring.

Why run a Slips, Trips, and Falls Toolbox Talk?

- Prevent unnecessary injury from slip, trips and falls by improving awareness and training

- Fewer injuries means higher productivity

- Makes sure workers know what to look for and what to do about it to reduce the risk of an injury occurring

What to watch out for that are common causes of slip, trips and falls?

- Poor housekeeping & messy sites

- Poor lighting

- Uneven walking surfaces

- Clutter on site

- Uncovered cords and cables

- Weather conditions (e.g. rain, ice, dust)

- Obstructed views

- Unsuitable footwear

- Distractions (e.g. cell phone, other workers)

What can you do to help prevent slips, trips and falls occurring?

- Keeping work areas clear & tidy from clutter, obstructions and rubbish

- Any waste placed in designated bins

- Clean up any leaks or spills immediately

- Put tools and equipment away

- Wear suitable footwear (e.g. grippy, anti-slip)

- Ensure work areas are well lit and sufficient light for work

- Keep cords and cables out of walkways, covered or secured

- Be aware of your surroundings and focus on what you are doing

- Work to the weather conditions

What if a slip, trip or fall occurs or nearly occurs?

- Report all slip, trip and fall accidents and near misses, with or without injury, this will help identify the hazards and implement control measures to prevent reoccurrence

Key takeaways

- Simply cleaning up your work area as you go, can help reduce slip, trips and falls

- Make sure you are always aware of your surroundings and look where you are walking

If you see a hazard that has the potential to cause a slip, trip or fall then pick it up or fix it – don’t wait for someone else to do it. Do it yourself!

Sales Inquiries Contact:

- AU 02 5104 6116

- NZ 09 886 3309

Support Inquiries Contact:

- [email protected]

- Help Centre

- Media Enquiries

- Toolbox Talk Topic Tool

- Health & Safety Consultant Directory

- Terms and Conditions

- Privacy Policy

- Account Owner Terms

- Facebook logo to SaferMe FACEBOOK PAGE

- Twitter logo to SaferMe twitter PAGE

This website requires Javascript for some parts to function properly. Your experience may vary.

Try Raken for Free - Connect with Sales

Slips, Trips, and Falls Safety Talk

Hazards on the jobsite can cause slips, trips, and falls. Learn how to protect yourself and prevent injuries.

Slips, Trips, and Falls Toolbox Talk

Construction sites are full of many hazards but most workers seem to forget about slips, trips, and falls. It is reported that nearly 15% of all accidental deaths are from incidents related to this. These types of accidents are also extremely costly to an employer and account for almost $11 billion with costs related to them. As a worker on a construction site, there are several precautions you can take to prevent an injury from a slip, trip, or fall. We will be looking into these a little further.

Slip, Trip & Fall Injury Statistics

According to the 2013 Liberty Mutual Workplace Safety Index, falls caused by slips and trips were the second leading cause of injuries and fatalities in the workplace. The number one cause is motor vehicle accidents. Slips, trips, and falls continue to be a leading cause of emergency room visits for many workers.

Some common slip, trip, and fall injuries include:

Broken bones

Back injury

Traumatic brain injuries

Causes of Slips, Trips, and Falls

Some common causes of slips, trips, and falls injuries include:

Wet or oily surface

Weather hazards including rain, snow, and ice

Loose mats and rugs

Walking surfaces that are not level

Obstructed views

Poor lighting

Uncovered wires and cables

Preventing Slips, Trips, and Falls

There are ways that you can help prevent slips, trips, and falls, and keep your worksite safer for you and your coworkers. One simple way is to practice good housekeeping, clean up as you go. Other ways include wearing slip-resistant shoes, being careful when walking on uneven surfaces as well as surfaces that are wet.

Good Housekeeping Tips

Good construction site housekeeping is an easy way to prevent most slips, trips, and falls and it is often overlooked. Simply cleaning up your work area as you go can help on the job site. Examples of good housekeeping include:

Cleaning up spills immediately

Mark areas that have spills and are wet until they are cleaned and dry

Mopping or sweeping debris from walking surfaces

Make sure walkways are free of clutter and obstacles

Securing mats and rugs that are not laying flat

Covering cables and wires that cross walkways

Making sure the work area and walkways are well lit

Clean your area as you work don’t leave the mess for others to clean

Check for fall hazards daily and alert your foreman if you see something

Have a laydown yard for extra materials and keep it picked up

Salt sidewalks, parking lots, and other highly traveled areas during winter ( Read more about preventing winter slips, trips, and falls )

Walking Surfaces Tips

Slips, trips, and falls can happen on any walking surface but, if that surface is uneven or if it is made of materials that provide little traction this chance can be increased greatly. Ways you can improve your walkways on your construction site can include:

Make sure there are mats or pressure-sensitive abrasive strips

Ask for the flooring to be replaced or painted if you notice it creates a hazard

Pay attention to where you are walking

If you notice a walking surface that is uneven or that needs some work bring it to the attention of your foreman so they can correct the issue if it is something you can not do. Also, make your coworkers aware of the hazard to decrease the risk of someone else getting hurt.

The footwear you chose to wear to a worksite has a huge impact on if you are safe. You should not wear tennis shoes on a worksite, always wear work boots. Your work boots should be the proper fit with treads to reduce the risk of slips, trips, and falls. To reduce your risks:

Wear work boots that fit snugly and that have slip-resistant soles

Clean the treads of your shoes regularly

Inspect the soles of your work boots and make sure they are intact and that you have proper treads

How you walk can have a big impact on your risk of slips, trips, and falls. When you are walking there are some ways to reduce these risks. This includes:

Take your time and do not run

Use light sources such as flashlights or installed light sources if your walkways are dark

Make sure if you are carrying materials or moving materials that you can see the walkways in front of you

Always look for spills when walking

Fall Prevention From Heights

A construction worker is more likely to get hurt by falling while pushing a wheelbarrow full of materials than they are while standing on scaffolding. However, it is still important to know how to prevent falls from heights above ground level. Some of these safety tips include:

Always use fall protection for heights over 4 feet.

Use proper guarding for holes and windows.

Use guardrails when needed.

Use adequate fall protection such as a full-body harness with a retractable lanyard that is 100% tied off to an approved anchor point.

When climbing ladders make sure to use proper ladder safety techniques .

What To Do If Injured

If you are injured on the job site you should report your injury to your foreman immediately. If you have a serious injury that requires immediate medical attention call 911 or have a coworker call for you. Should you see that a coworker has been injured do your best to notify someone and get immediate medical attention for them. While some slips, trips, and falls may seem minor at first it is always better to get fully checked out. Sprains and strains to your legs, ankles, and back are common with falls on a worksite. Broken bones are also common and need to be treated as soon as possible.

Do Your Part in Preventing Slips, Trips & Falls

A common safety hazard on construction job sites are slips, trips, and falls but they can be prevented with some safety measures. Make sure you are always aware of your surroundings and where you are walking. Also if you see a hazard let your coworkers and foremen know immediately. Working together to keep your worksite clean and hazard free is the best prevention. Should you have any questions about hazards on your job site or what to do ask your foreman.

Find and schedule topics faster

Raken's toolbox talk app makes it easy to choose from a pre-loaded library (or upload your own), then schedule and assign topics for any project. We'd love to show you how in a demo, and get you started on a free trial.

Download a PDF of this toolbox talk

Thanks! Check your email for a link to access your PDF.

We're committed to your privacy. Raken uses the information you provide to us to contact you about our relevant content. You may unsubscribe at any time. View our privacy policy .

Related Toolbox Talks

- 3 Poor Housekeeping Hazards Toolbox Talk

- Housekeeping Toolbox Talk

- Falls on the Same Level Toolbox Talk

- Work Area Best Practices Toolbox Talk

We use cookies to manage and improve your website experience.

29 Key Toolbox Talk Topics For Construction In 2020 [Download]

Coming up with new toolbox talk topics for construction businesses can prove tricky after a while. This is why it is handy to have a cheat sheet available! If you think you may have exhausted all possibilities when it comes to themes for your informal safety meetings, take a look at this list, find a subject, download an example talk, and think about how it relates to your workplace.

Why Are Safety Talks Important in Construction?

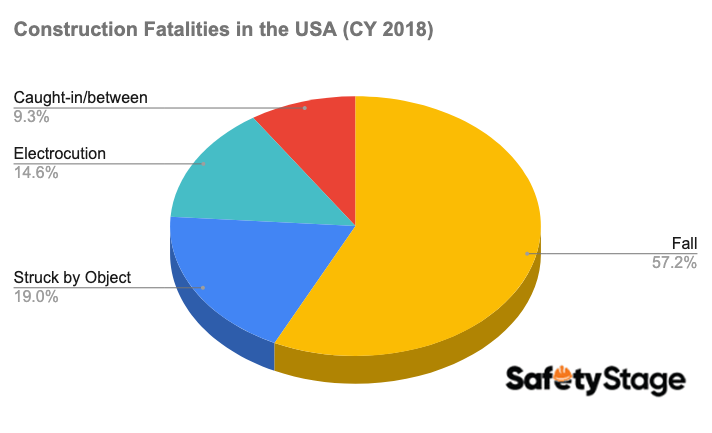

Regular short safety meetings at the start of a day are a great way to remind workers of their obligations and the best practice within your company in a relaxed learning environment. They refresh knowledge, keep workers up to date with the latest developments, and ensure that safety is always front of mind as your employees begin work for the day. In 2018, 21.1% of the 4,779 worker deaths occurred in the construction industry, according to OSHA statistics, which proves exactly how important it is to hold regular safety talks in the construction industry. The agency found that the majority of accidents fell in four distinct groups and, based on this, it outlined the “ Construction Focus Four Hazards ” — the most important toolbox talk topics.

29 Key Toolbox Talk Topics For Construction (Free Download)

Here is a list of important toolbox talk subjects for construction, along with downloadable files that you can use for your organization.

The Construction Focus Four

1. fall hazards & protection.

Whether someone works at the top of skyscrapers or just a few feet off the ground on a building site, a fall can be fatal. Around a third of deaths in the construction industry come as the result of a fall on job sites. This is why it is important to remind employees of the types of fall protection equipment available for different tasks, how to maintain it, and how to inspect it before starting work.

DOWNLOAD FREE TOOLBOX TALKS

2. Protection From Falling Objects (Struck-by Hazards)

Besides trying to prevent injuries from dropped objects, you should include a topic on protecting oneself from falling objects in a toolbox talk. How can workers prevent objects from falling and how can they ensure they are at the lowest possible risk of suffering an injury from a falling object?

DOWNLOAD FREE TOOLBOX TALK

3. Excavation (Caught-In -Between Hazards)

Excavation has one of the highest fatality rates in the construction industry, with crushing caused by collapsing work one of the biggest risks. Other risks include electric shock from hitting power cables, poor quality air, toxic fumes, and water bursts. Your talk should focus on how to prevent these risks from developing into an on-site incident.

4. Electrical Safety

Not only should you provide toolbox talks for trained electricians on site, but you also need to guide non-electricians on all aspects of electrical safety. From hazards such as using electrical equipment near water to lock out tag out procedures, there are a plethora of subjects you can cover to keep workers safe.

DOWNLOAD FREE TOOLBOX TALK

More Construction Toolbox Topics

5. working at heights.

Preventing falls is a key area of focus for toolbox talks on working at heights, too. In addition, another risk factor is dropping objects onto people below from height. It is important for workers to understand how to protect themselves and others on-site, as well as the public.

6. Confined Space

A confined space is any working area where the entrance or exit is difficult to move through or restricted in some way. The Department of Labor reports that 92 workers die in confined spaces every year.

Confined space is so important that Jordan Barab named his entire blog after it. When it comes to toolbox topics about confined space, it is key to cover the risks, including poor oxygen supply, toxic gases, exposure to flammable substances, or other hazards that are amplified even further by the restrictions placed on the worker’s escape in the event of a problem. Workers in these environments can benefit from regular training on risk management directed specifically at these situations.

DOWNLOAD FREE TOOLBOX TALK

7. Working on a Platform

There are different types of aerial work platforms and it is important to stress the necessity of approaching their use in different ways to ensure safety on site. Advice on inspections and operating procedures for both man lifts and scissor lifts help workers continue to use these helpful pieces of equipment in a safe manner.

8. Fire Safety

Helping employees understand how fires occur, the hazards they can cause, and the ways in which they can extinguish them is vitally important. A fire can wreak havoc on a construction site, delay projects by weeks or even months, and, of course, lead to fatalities. So, be sure to remind your staff where to find fire extinguishers and fire drill processes in the event of a fire.

9. Asbestos Awareness

There are a huge number of risks involved with inhaling asbestos dust, from lung disease to cancer. However, when working in the construction industry, there will be times when employees have to come into contact with it in the work environment. When renovating or demolishing old buildings, it is a constant threat. This means that your workers should know how to identify asbestos and the measures they can take to protect themselves as they carry out their work.

10. Slips, Trips, and Falls

More workers are injured in the workplace through a slip, trip, or fall than any other reason. More than a fifth of falls lead to more than 31 days of work missed per year , showing exactly why it is important to keep the message of safety and slip, trip, and fall prevention in workers’ minds.

11. Forklift Safety

Although forklifts are essential to construction sites, they can also prove to be a hazard. Uneven loads, overloads, careless driving, and a number of other factors can all come into play when considering the workplace risks of forklifts. Make sure you discuss maintenance, operation, and any other subjects relevant to your site.

12. Aerial Lift Safety

There are a number of risk factors involved with aerial lifts, such as fall hazards, electrical hazards from overhead cables, and the potential to tip the vehicle when using it. In order to prevent accidents from happening, your talk can look at planning, operation, and vigilance while using aerial lifts in the workplace.

13. Good Housekeeping

OSHA lays out standards for housekeeping in its regulations, and all construction sites must adhere to them. Of course, you will have to tailor this good housekeeping toolbox talk to your specific workplace rules, as every site will have its own policies on what is stored where. In any case, this is a great opportunity to remind your staff of their duties to leave the site in a neat and tidy manner, where everybody knows where each essential piece of equipment should be and can be confident that they won’t walk into an unnecessary hazard.

14. Manual Handling

You should talk to your workers about prioritizing mechanical handling at all opportunities, as a safer alternative to manual handling. They should learn about the considerations they must make before they handle the articles in question and the techniques they should adopt for the safest practice.

15. Face Protection

There are many elements to face protection toolbox talks. You can concentrate on the eyes or the face in general. Impart knowledge on protecting these sensitive features during the types of tasks workers will generally undertake in your workplace. You can offer insight on PPE, prevention of accidents, and first aid in case of an incident.

DOWNLOAD FREE TOOLBOX TALK

16. Repetitive Injuries and Ergonomics

Help your employees recognize the early symptoms of repetitive injuries and provide them with the resources and knowledge they need to take evasive action. Also, stress the importance of reporting any issues that may be due to ergonomics in order to allow the business to remedy potential causes.

17. Lightning Safety

With most construction work taking place outdoors, it is imperative that workers can spot the signs of an incoming storm. They should also know the best precautions to take if they can find shelter as well as if they can’t, and what they should or shouldn’t do while waiting for the storm to pass.

18. Ladder Safety

One of the key elements of ladder safety is choosing the correct ladder for the job. Workers should be able to make informed decisions in order to remain safe while using ladders in the workplace. Talking about the basics of ladder use in safety discussions and considering ways to keep safe on-site while using ladders are important topics for your construction toolbox talks.

19. PPE Use

OSHA insists that you need a PPE program in place if personal protective equipment is necessary at your workplace. In order to conform to this recommendation, workers need to know about the general types of PPE in use across industries, as well as those construction-specific pieces that they will need to use in their job.

20. Vibration

Workers should be able to detect the early symptoms of hand-arm vibration syndrome and know what steps to take next in order to reduce the risks of it becoming acute. Being able to understand the vibration rating system is another key skill for anyone using equipment at work that can cause such issues.

21. Scaffolding

More than 4,000 workers every year suffer a fall as a result of a safety failing to do with scaffolding. With this in mind, refreshers on how to properly secure and use scaffolding, along with the various regulations that you must meet, are integral elements of your toolbox talk on scaffolding.

22. Hand Tools

Hand tools can form the basis of a number of different types of toolbox talks. You could discuss the ergonomics of the tools, potential injuries that they can cause, and also guide your staff on how to select the correct hand tool for the task they are undertaking.

23. Near Miss Reporting

In order to impress upon employees the need for participation in near miss reporting, you can host a toolbox talk about the Accident Pyramid that shows the relationship between near misses and incidents in which someone is hurt. This will help staff see how important their role in exposing risks is.

24. Sprains and Strains Prevention

Sprains and strains are responsible for around a third of injuries in construction. This is why it is important to remind workers of the policies you have in place to prevent such issues and the many ways they can minimize their risk of suffering from them during their regular tasks.

25. Yard Hazards

Yard hazards can refer to any potential safety issue in the general construction site. Talks on this topic range from creating safe working zones to the dangers of silica, as well as how to patrol the traffic on-site in a safe manner.

26. Hazard Communication / GHS

Hazard communication reduces the risk of chemical-related incidents by ensuring that labeling meets a strict standard. This way, everyone on-site can tell just by looking at a container what it holds and how to deal with it accordingly. Both the implementation of this program and the understanding of the system for hazardous substances are both key learning areas for these talks.

27. Harness Inspection

The detail of what you need to inspect to ensure your harness is fit for purpose is rigorous and necessary for avoiding workplace safety incidents. Employees should be well versed in looking for wear and tear in all areas of the harness, from the labels to the webbing. They should know how to clean and store it safely, and how to tell if lanyards are still in an adequate state to complete their purpose.

28. SRL Usage

SRL stands for self-retracting lanyard, which forms an integral part of working at height, preventing injury and death. However, when not properly used they can pose a risk to the worker, so it is imperative that they are up-to-speed with the correct usage and maintenance requirements.

29. Guardrail Safety

If you want to drastically reduce the risk of falls from wall or floor openings, then guardrails are an important piece of the puzzle. Employees should know when and how to install them, where they should be located and what specifications they should meet.

Bonus: Video Toolbox Talks

An alternative to giving a toolbox talk yourself is to show your workers a video on the topic. Watch these videos to gain inspiration for your next talks:

- Confined spaces video toolbox talk

- Electrical safety toolbox talk

- Scaffolding safety toolbox talk

- PPE toolbox talk

- Guardrail safety toolbox talk

5 Steps to a Successful Toolbox Talk For Construction

- Make it Relevant – Your talk should be relevant to your industry and even your individual workplace. By focusing on the details your workers see every day, you make it chime with them and help them see how this is helpful to them and their colleagues in the real world. Either make up examples they would recognize or use real events to inspire your talk.

- Keep it Brief – Long-form lessons are for safety courses. A toolbox talk is usually a quick catch-up, packed with relevant information and light on filler. So, aim for short workplace safety topics , get to the point quickly and let the audience get on with their work shift.

- Make it Positive – No one wants to start the day with a gloomy, foreboding warning. Talk about how you can all make the site safer, rather than concentrating on how dangerous it can be. And, why not, try some funny safety moment ideas .

- Interact – Ask questions, punt for stories, include a demonstration. People are more likely to engage if you capture their attention and punctuate the learning with aspects other than a long monologue.

- Check Everyone Understands – This is vitally important. Before everyone disperses, find out if they took everything in. Ask for questions or issues that the talk raised. There is no point in giving a talk if no one remembers what you were talking about.

Q. What is OSHA’s Focus Four?

A. OSHA’s Focus Four are the four hazards that form the basis for the majority of workplace incidents. They are:

Q. How do you write a good safety briefing?

A. A good safety briefing should be short and to-the-point. You need to make sure everyone understands what you are saying, so you need to consider the requirements of those for whom English is a second language. Keep a consistent message throughout to make sure you make your point and look for examples that speak to the audience you are talking to, whether it is something that they experience or that concerns them. To get a better idea, check out these safety moment of the day examples .

These toolbox talk topics for construction will help you grab the attention of your workers, refresh their memories, and set them up for the day to be the safest they can be. Coming up with fresh ideas every day is tough, but remember that there are so many ways to talk about safety in construction and these subjects are just the jumping-off point for your successful toolbox talks. Much of it is common sense, but we all need help to inspire us sometimes.

References & Further Reading

- Tips from Ergo Plus

- The Center for Construction Research and Training

- OSHA’s Construction Advice

- Guide To Improving Safety Culture In The Workplace

- Workplace Safety Games

- LTIR Calculation

Related Posts

8 important march 2023 safety topics to cover + spring safety tips, 7 interesting february safety topics to cover in 2023, 8 december safety topics for a safer holiday season at work.

Type above and press Enter to search. Press Esc to cancel.

ONLINE TOOLBOX TALK GENERATOR

Slips, trips, and falls toolbox talk.

Disclaimer: We respect your privacy and do not retain any generated PDF documents or policy amendments. Once you leave this page, all changes will be lost. We recommend that all policies are reviewed by the relevant SHEQ Manager or legal team before circulation. Remember to download and save your documents, as we can’t recover them. If you have any questions, please contact us.

Fill in the fields to generate your free Slips, Trips, and Falls TBT

Toolbox talk description:.

The Slips, Trips, and Falls in Construction Toolbox Talk Template at The Health & Safety Zone is an essential resource for construction site managers and safety professionals. This template provides a comprehensive guide for conducting safety talks focused on preventing slips, trips, and falls on construction sites, which are among the most common causes of workplace injuries.

Key Insights and Safety Tips

- Effective Site Management : It’s crucial to manage the construction site in a way that allows safe movement around the site, keeping it clean and orderly to reduce injury risks from slips and trips.

- Hazard Identification and Management : Pay attention to common hazards like uneven surfaces, obstacles, trailing cables, wet or slippery surfaces, and changes in level. Proactive measures like proper housekeeping, planning deliveries, and maintaining walkways can significantly reduce these risks.

- Practical Prevention Strategies : Encourage workers to use designated walkways, wear appropriate footwear, and use mechanical lifting aids instead of carrying heavy loads that block vision. Ladder and scaffolding safety are also critical to prevent falls from height.

Customisable for Your Specific Needs

- This template can be tailored to address the unique safety challenges and protocols of your construction site, ensuring relevance and effectiveness in your safety communication.

Simplifying Safety Communication

- The online document generator at The Health & Safety Zone makes it easy to customise and distribute this vital safety information to your team, ensuring that everyone is aware of the best practices to avoid slips, trips, and falls.

Useful Resources and Links

- HSE Guide on Preventing Slips and Trips at Work: https://www.hse.gov.uk/pubns/indg225.htm

Meta Description: “Enhance construction site safety with our Slips, Trips, and Falls Toolbox Talk Template. Customisable and comprehensive, this resource is crucial for educating your team on preventing common job site injuries.”

Sample PDF Document Image:

Frequently Asked Questions:

A Toolbox talk on Slips, Trips, and Falls is essential to educate employees about common workplace hazards, promote awareness, and emphasize preventive measures to reduce the risk of accidents and injuries.

Common causes include wet or slippery floors, uneven surfaces, cluttered walkways, inadequate lighting, and improper footwear. Identifying these factors is crucial for prevention.

The talk should cover safety tips such as keeping work areas clean and organized, using appropriate signage for hazards, wearing suitable footwear with good traction, and promptly reporting and addressing any safety concerns.

Toolbox talks on this topic should be conducted regularly, particularly when new hazards arise or when reviewing workplace safety. The frequency may depend on the specific workplace conditions.

Employees should immediately report any slip, trip, or fall incident to their supervisor or the designated safety authority. Additionally, they should seek prompt medical attention if injured, even if the injury appears minor.

PLEASE WAIT DO NOT CLOSE THIS PAGE We are generating your PDF File Thank You for using the Health & Safety Zone!

Home / blog / Toolbox Talk: Slips, Trips and Falls

Toolbox Talk: Slips, Trips and Falls

by Walker Safety · December 13, 2021

Why have this talk? Every year many accidents resulting in injuries occur through slips, trips, and falls. Most of these slips, trips and falls that occur are easily preventable with a little consideration and care.

What will this talk cover? The causes and prevention of slips, trips, and falls.

What causes slips, trips and falls?

- The most common reason for injuries from falls is poor housekeeping, ie mess. Items lying about will trip someone up if not put away in a safe place.

- Where oils and grease are used, spills will create a slip hazard if not immediately cleaned up.

- General debris from building works can quickly accumulate and form a tripping hazard.

- Trailing cables are another frequent cause of tripping.

- Mud left on equipment surfaces or ladder rungs will represent a slipping hazard for the next person.

- Reduced levels of natural light, for example during winter afternoons, can easily increase the tripping hazards if adequate access lighting is not provided. Tools, equipment, and materials that are visible in full daylight will be harder to spot in reduced lighting.

How to prevent slips, trips and falls

- Clear up waste materials as you create them. Lightweight waste should be bagged or bundled, and all sharp objects removed, eg nails from waste timber.

- Do not leave tools, equipment or unused materials lying about on the floor.

- If you are using substances which could spill, ensure that you have a means of effectively clearing up any spillage.

- As far as possible, cables for work equipment should be secured above head height. If cables must be routed at floor level, try to avoid crossing pedestrian walkways and use fluorescent or warning tape to highlight potential trip hazards at floor level.

- If the workplace is muddy, scrape off mud from footwear before using access equipment or walking anywhere that may be a danger to others.

- Be aware of the increased risks of tripping as the level natural light fades; use additional lighting and ensure that all tools, equipment, and materials are stored in a safe location.

Questions for employees

- What can you do in your job to reduce slip, trip, or fall hazards?

- How can you manage the risk from trip hazards at floor level?

- What is the correct procedure for clearing up a spilt liquid?

- How can you improve workplace lighting as the sun sets?

Do you have any questions for me?

Contact us if you require further assistance.

Find this helpful?

Signup to our email notifications to receive alerts when we publish new blogs. We promise not to spam your inbox, you will just get a short snappy intro to Health and Safety blogs we think you will love.

Your email:

You may also like...

H&s update.

April 24, 2014

Tips to Ensure Your Workers are Adequately Trained

September 19, 2016

Improving worker involvement

October 29, 2018

- Accident Advice

- Company Updates

- Construction Health and Safety

- Coronavirus

- Equipment and Machinery

- Health and Safety

- Health and Safety Compliance

- Mental Health Advice

- Office Health and Safety

- Regulations Updates

- Tips and Advice

- Uncategorized

RECENT POSTS

- Occupational Health Support

- Personal Protective Equipment at Work (Protected Characteristics) Bill tabled in Parliament

- Get ready for the first No Falls Week

- Finally finding safety equipment that fits

- Premises Maintenance

SUBSCRIBE TO EMAIL NOTIFICATIONS

- Testimonials

- FAQ’s

- Regulations

- Terms and Conditions

- Health and Safety Management

- Risk Assessments

- Audits and Inspections

- CDM Regulations

- Accident Investigation Support

- Policy Writing

Walker Health and Safety Services Limited, Suite 6, C1, Coalport House, Stafford Court, Stafford Park 1, Telford, Shropshire, TF3 3BD

Telephone: 0845 834 0400 Fax: 0845 834 0401 Email: [email protected]

Plan Your Lyubertsy Holiday: Best of Lyubertsy

Explore Lyubertsy

Essential lyubertsy.

Lyubertsy Is Great For

Eat & drink.

IMAGES

VIDEO

COMMENTS

Slips, trips and falls are a common reason for many of the injuries in workplaces. They can cause minor injuries but can also lead to serious, long-term injuries. Many slip, trips and falls are avoidable and there are usually easy solutions a workplace can apply to control the risk, either by eliminating or minimising it.

Slips, Trips, and Falls Toolbox Talk. Construction sites are full of many hazards but most workers seem to forget about slips, trips, and falls. It is reported that nearly 15% of all accidental deaths are from incidents related to this. These types of accidents are also extremely costly to an employer and account for almost $11 billion with ...

Most injuries from slips, trips and falls result from poor housekeeping practices. Examples of slip, trip and fall hazards include: • Items such as trailing cables and hoses, hand tools, lengths of pipe or timber etc. left on the ground may cause someone to trip up. • General rubbish such as pieces of brick, material off cuts etc. can ...

Slips, Trips, and Falls . Most injuries resulting from falls aren't caused by falls from over head, as you might think. They are from falls at ground level or floor level where we walk and work. Here are some tips to avoid Slips, Trips, and Falls : • Housekeeping of a high standard is most important to maintain a safe work area. Don't

Slips, trips, and falls are the second most common cause of workplace injuries in the United States. In this video we look at the causes and prevention and h...

DOWNLOAD FREE TOOLBOX TALK. 10. Slips, Trips, and Falls. More workers are injured in the workplace through a slip, trip, or fall than any other reason. More than a fifth of falls lead to more than 31 days of work missed per year, showing exactly why it is important to keep the message of safety and slip, trip, and fall prevention in workers ...

Falls are when you lose contact with the walking or working surface and fall. Falls can occur either on the same level or from an elevated surface. Falls from an elevated surface are second only to motor vehicle accidents in the cause of work place fatalities. The hazards which result in slips, trips and falls generally can be grouped into ...

Most workplace falls which cause injury or death are falls from the same level, not from heights. EXAMPLE You may be in a hurry and run down a flight of stairs, or walk a corridor while reading instructions. You might slip on a slick surface and suddenly your feet go out from under you. Falls can also be caused by tripping on an obstacle - your ...

Date Posted: 01/30/2024. According to the Bureau of Labor Statistics (BLS), nearly one-third of reportable injuries and 40% of fatalities in construction result from slips, trips, and falls nationally. These injuries result in 50% more days away from work than other injuries. Slips, trips, and falls are among the top three causes of work ...

10-minute safety talk. Slip, trip, and fall. hazards. Key takeaways: • Many workers are hurt due to slips, trip, and falls. • Housekeeping is key to preventing slips, trips, falls. • Keep walkways and paths in good condition and free of items and debris. • Move with a clear view of surroundings, have good footwear tread, and avoid ...

Slips, trips, and falls cause nearly 700 fatalities per year and many more injurious accident in the workplace according to the Bureau of Labor Statistics. There are three physical factors involved in slips, trips, and falls: friction, momentum, and gravity. Each one plays a role. Friction is the resistance between objects, momentum is affected ...

In particular, slips and trips are a common cause of injury to personal care and nursing assistants, cleaners and sales assistants. Slips, trips and falls are a significant problem affecting every workplace, from factory floor to ofice. They can result in serious injury and lengthy amounts of time off work.

Enhance construction site safety with our Slips, Trips, and Falls Toolbox Talk Template. Customisable and comprehensive, this resource is crucial for educating your team on preventing common job site injuries.

7 Tips for Preventing Slips, Trips, and Falls. Fortunately, most slip, trip, and fall incidents are avoidable. By using the right safety tools and training employees, companies can prevent these incidents from happening in their workplaces. Safety officers should take note of the following aspects to keep their workplaces and fellow employees ...

This talk will cover: the causes and prevention of slips, trips and falls. 1. Most injuries from slips, trips and falls occur because of poor housekeeping. 2. Many items such as coiled cables, hand tools, lengths of pipe or timber etc left on the ground will trip someone if not deposited in a safe position. 3.

Several thousand construction workers are injured each year following a trip or slip whilst at work on a building site. Around 1000 of these injuries involve someone fracturing bones or dislocating joints. Most could be avoided by the effective management of working areas and access routes, such as stairwells, corridors, footpaths and site cabins.

Slips, Trips, and Falls. Slips, trips, and falls cause many disabling injuries and deaths each year. These accidents usually result from poor housekeeping practices, and can take place anywhere: the office, the construction site, or the home. Prevent slips, trips, and falls by being proactive: observe your environment and PLAN your movements.

Toolbox Talk: Slips, Trips, and Falls Safety Talk Slips, trips, and falls are one of the leading causes of injuries and fatalities in the workplace. According to OSHA, slip, trip, and fall incidents cause 15% of all accidental deaths, and are second only to motor vehicle incidents as a cause of fatalities on the job.

The most common reason for injuries from falls is poor housekeeping, ie mess. Items lying about will trip someone up if not put away in a safe place. Where oils and grease are used, spills will create a slip hazard if not immediately cleaned up. General debris from building works can quickly accumulate and form a tripping hazard.

Search 42 Elektrostal' local handyman services to find the best handyman service for your project. See the top reviewed local handyman services in Elektrostal', Moscow Oblast, Russia on Houzz.

Just answer a few questions to get matched with a local General Contractor. Or browse through the list of trusted General Contractors in Elektrostal' on Houzz: See Elektrostal' Ge

Heat-ex is located in Elektrostal. Heat-ex is working in General contractors, Heating installation and repair activities. You can contact the company at 8 (495) 505-21-45.You can find more information about Heat-ex at heat-ex.ru.

Lyubertsy Tourism: Tripadvisor has 1,952 reviews of Lyubertsy Hotels, Attractions, and Restaurants making it your best Lyubertsy resource.