- Forum Listing

- Marketplace

- Advanced Search

- Classic Forums

- General Cycling Discussion

Domane Isospeed Decoupler Fail

- Add to quote

I have a question about the Isospeed decoupler on my 2015 Trek Domane 5.2. Recently I noticed that the decoupler was not dampening the ride like it used to. When I took it into the LBS for service they said they could just replace it and it would be fine. Once they got it apart they said that it had corroded most likely from sweat and had seized internally. When they tried to replace it they said that the outer race had "fused" to the frame and in order to get it out it will like break the frame and render it unusable. They submitted a warranty claim to Trek but it was denied as a lack of maintenance issue as opposed to a manufacturing defect. LBS says the options are order new frame (which will entail replacing the brakes as the design has changed and cost $1500) or buy a new bike. Now I will admit that I did nothing in terms of maintenance for the decoupler beyond washing regularly. So I took in a bike that at least I could ride to the LBS and now it is totally unrideable, useful only to harvest the components. Questions: Has anyone else had any issues with the Isospeed seizing and fusing to the frame? Should I pick up the bike and take it to another LBS for second opinion? Thanks

I work at a Trek owned shop and I have never once seen one that's stuck in the frame. Bottom bracket and headset bearings are another story.

Curious if it’s in the owners manual to have maintanence done on a regular basis for the Isospeed systems. If not, I’d have a beef with Trek.

Yep, me too. If the thing froze up and stuck in the frame, it was the weak link in the system and failed. Whatever forces it had to handle overcame its capabilities. Faulty design. Do those things actually improve the ride, or just soften it up? If so, is that good or bad? Is the tradeoff worth it? Can they handle a heavy rider? How long before they take one too many hits and start to come apart? Frankly, I'd go back to solid tubes. One less thing to worry about.

Agree with Steve. If Trek hasn't got enough real world experience with this design to have written up specific maintenance instructions for that area of the frame, and you have routinely cleaned the bicycle, then I think this is all on them.

And I quote: " The IsoSpeed mechanism is designed to last the lifetime of the bicycle without service. Do not lubricate it. Keep it clean with water and soft cloth. If the mechanism makes noise or exhibits lateral play, the design allows easy replacement of the mechanism. Take your bicycle to your retailer for service" Pg 39: https://trek.scene7.com/is/content/...Library/Bike OM_withWeightsAddendum_en-US.pdf accessed via: https://www.trekbikes.com/us/en_US/manuals/ Bold emphasis mine. I'd pick a bone with them. Basically reads "don't mess with it until something is wrong with it--then we'll fix it". Which is exactly what the OP did, and Trek ain't doing.

Did you buy it from the LBS you took it to? If yes I'd have a real problem with the LBS not giving you the support in the warranty claim. You could try another dealer but maybe go direct to your area Trek rep. I'd be pissed if you have followed their instructions and then they try and blame you for doing just that.

I would press Trek on this one too. I'd also do some work with good penetrating oil for a couple weeks to see if it wouldn't loosen up before scrapping a frame.

Thanks for posting the Trek manual instructions; that was useful. I think the OP should bring the manual along with the bike back to the shop and try again. If that fails, try a second shop. If THAT fails, contact Trek directly and see what they say. Report back with your resolution. I'm with Fredrico; too many parts, and just something else to go wrong or creak.

If the manual says no maintenance required, just keep it clean, the owner does that and it fails, it's their fault, not the owner's. They should take the frame back, replace the coupler, or frame if necessary, and call it a day. Those things aren't supposed to happen on a bike that costs as much as a late model used car. :nono:

I'd like to know if the OP purchased the bike (new) from an authorized dealer. Maybe this is the reason his warranty claim was denied. "Trek Bicycle Corporation provides each original retail purchaser of the bicycle a lifetime warranty against defects in materials and workmanship in the bicycle frame and rigid fork when purchased from an authorized Trek dealer."

ngl said: I'd like to know if the OP purchased the bike (new) from an authorized dealer. Maybe this is the reason his warranty claim was denied. "Trek Bicycle Corporation provides each original retail purchaser of the bicycle a lifetime warranty against defects in materials and workmanship in the bicycle frame and rigid fork when purchased from an authorized Trek dealer." Click to expand...

Hope that things work out better than they are looking right now for the OP and his problem with the LBS/Trek. I live in a very popular recreational bike use area. My current ride is a Trek Domane with about 15,000 miles on it. The LBS I use has four locations within a ten-mile radius. Every problem I've had with the bike Trek has been stellar as has the LBS on my behalf in "dealing" with Trek on the issue. In my specific area Trek riders that use the four stores are high on Trek for having a strong warranty that they adhere to consistently. I suspect that the individual LBS part in the whole process can have a major impact. Regarding ride quality, the ISO Speed Decoupler definitely improves the ride comfort of the bike IMO. I have only the rear. The feedback I've gotten from other riders is that bikes that have it on both rear and front are even better riding.

I got this reply from Trek....... and it seems like the OP has hit and run.

Attachments

"I cannot say I know what is actually going on behind the scenes. It appears that Trek is now demanding stores to carry 80% Trek for a shop to be able to call themselves a Trek Dealer and must carry 60% Trek for a shop to be able to sell Trek bikes at all or even to get support.' I cannot expect that this is true for all shops. There must be a required dollar amount generated or something similar, to allow a shop to skip these percentages that need to be Trek. A very large LBS locally - Brands in Wantagh, NY which has been in business 60 year or better, lists 19 different brands of bicycles such as Specialized, Cannondale, GT, Giant etc.... all major Trek competitors. I cannot expect that this LBS will meet those percentages of Trek vs. other brands sold. This shop in particular is so big that I might assume that it's in Treks interest to be represented here and that there is likely a different agreement in place.

My thought hearing this is that everything is negotiable. My shop is small, but very busy and popular, so they do quite a volume as far as repairs, but probably don't sell as many bikes as bigger shops.

Szlmdm said: They submitted a warranty claim to Trek but it was denied as a lack of maintenance issue as opposed to a manufacturing defect. LBS says the options are order new frame (which will entail replacing the brakes as the design has changed and cost $1500) or buy a new bike. Click to expand...

Fredrico said: Do those things actually improve the ride, or just soften it up? If so, is that good or bad? Is the tradeoff worth it? Click to expand...

PoorInRichfield said: I've seen barely ridden Domane 5.2's on Craigslist for about $1,500... if I didn't already have one, I would've bought them! Anyway, from Trek's perspective, they have no idea what was poured on the Iso Decoupler and under "normal conditions", it doesn't seize-up. I'm not saying you did anything wrong, but perhaps the water you wash your bike with or your sweat is unusually corrosive. A warranty certainly won't protect everyone from everything. I personally have had great success with Trek warranties from my LBS... they even replaced a mountain bike wheel that I specifically told them was damaged in an accident :blush2: I also have a Domane 5.2 and I'd say the ride between a regular road bike and a Domane is like being hit with a regular hammer versus a rubber mallet It doesn't turn every ride into a plush, pillowy dream, but certainly takes the edge off of a normal road bike. I love my Domane and would easily buy another one. Click to expand...

Hey @Szlmdm, if you haven't had a chance to call into our warranty department, I would call 1 (800) 585-8735. Sometimes details from the shop's claim entry might not depict the issue where the warranty team can properly grasp the problem. We're always willing to chat about it on the phone, just get your claim number from the shop (if possible) so that the warranty team can quickly pull up the information!

Can the OP post up a pic of the decoupler in question?

Hey Mitch, good on you for reaching out to the OP.

My thought too.

UPDATE: Thanks to the many that offered helpful advice. I did take the reference page from the Service Manual back to the LBS. They contacted their regional rep from Trek and they have now agreed to replace the frame with a new one or apply the frame replacement price to a new purchase. The downside with the replacement frame is that by the time we replace brakes, seat post (both due to new design) and consumables such as cassette, chain, cables, etc. plus labor it will be $800. The upside is I will have pretty much a new bike! I am also exploring upgrading to a new disk version so I haven't yet made the decision but will close in on that soon. In the end, the LBS went back to bat for me and Trek did the right thing. Again, thanks for the advice provided.

Thanks Mitch. It appears that we have it worked out. After further review Trek is going to replace the frame.

I'm happy to hear it worked out! There is a great group of people on these forums, so good on everyone for providing assistance!

Woohoo! So you'd get one of the new frames with the front and rear ISO decouplers? I'd do that for $800. As for the disc brakes, make sure you price-out how much the brake levers cost... Ultegra brake levers with hydraulic brakes are $$$$. Not saying you shouldn't got that route, just make sure your budget can handle it.

You are going to love the new ride. I went with disc and They are great. The ride with wide tires is awesome. Disc brakes cost more to maintain tho

Don't have a pic and the frame is on its way back to Trek for analysis. On my 2015 version of the Domane the Isospeed decoupler is on the top tube about an inch from the seat post. You can see pics in the Trek service manual.

Trek said: According to Specialized, the steerer tube collar on these Future Shock-equipped bikes is at risk of "stress corrosion cracking", which could lead to a sudden loss of steering control. Click to expand...

.je said: Too bad they didn't recall this Click to expand...

Szlmdm, post a picture of your new bike when you get it!

I have a 2015 Domane 5.9, nearly 4 yr old now with 21,000 miles. I bought it because my 1999 Trek 5200 has performed almost flawlessly for about 38,000 miles. My 2015 has been kept in a humidity controlled environment for its entire life and obsessively k ept clean, although not routinely brought into a shop. I recently took it into the nearby Trek shop and was told that the corrosion of the isospeed assembly was so severe they could not remove the old isospeed parts to replace them. The recommendation was to have them strip all the components off and send the frame to Trek to try to remove the pieces. If Trek broke the frame they would not be responsible and would only give me 20% off a new frame, which they would do even if I told them my bike fell off the car and got run over! After I submitted a scathing on-line review of the performance of Trek and the shop, it was suggested that I bring the bike to the other Trek shop in town, where they said they had dealt with the outer bearing race being corroded and stuck in the frame. They used a Dremel tool to cut it out a piece at a time. They were successful. The shop did not charge for their labor and submitted a claim to Trek for the replacement parts, quoting the Trek manual (pg 39...thanks for posting that critical piece of info!) which effectively said don't lubricate the isospeed . My conclusion: Trek screwed up in several ways...poor choice of materials for the isospeed bearings, ridiculous advice saying there's no need to maintain the isospeed, irresponsible stewardship by recognizing that the corrosion issue exists but not notifying customers to bring the bike in for inspection to prevent extreme consequences. Kudos to the 2nd Trek shop who did handle the situation professionally and succeeded in resolving the problem.

Another example of Trek Fail. 2nd Shop +1.

I thought I'd mention a problem I currently have with my Domane SLR7. I took it for a service and they found that the hole in the seatpost where the Isospeed pivot fits had worn and was oval. The shop mechanic (a Trek only dealer) tells me he's never seen this before and as Trek don't supply just the seatpost he said I might need a new frame. Fortunately another SLR had come in at the same time with a broken chainstay so they have fitted the seatpost from that - at no cost. Although I'm happy with the outcome, I think it should have been a new frame under warranty.

Okay, this is a very misleading post. The IsoSpeed pivot is not in the seat post at all - it is in the seat tube, which cannot be replaced as it is an integral part of the frame. You had a problem with the seat mast cap, which has nothing to do with the IsoSpeed design as it is also used on the Emonda. There is no way that replacing a seat mast cap could "fix" an ovalized pivot hole in the seat tube.

So, I have purchased 2 Trek bikes. My mtb and my daughter’s commuter. I have been very happy with my local Trek dealer and both bikes. I have not had a warranty issue. This thread makes me less, not more, comfortable about working with the company. I have confidence in my local shop, but this post gives me pause. Do I need to blow up on social media to get my warranty honored? I’m thinking I may have made my last Trek purchase. Go ahead and be Specialized. Just go without me.

Absolutely not the case - you shouldn't have to jump through hoops to get help from us ever. We have a great warranty team in place that is always an email or phone call away for those who prefer to speak with them and they back our retail network by offering their full support. We try to make a warranty claim as painless as possible without having to jump through hoops. All you ever need to do is bring your bike into your local Trek dealer and they will take it from there. If you ever had questions regarding a claim, our team would be happy to chat!

An old discussion rises again... I'm reading this because I too have a 2015 Domane 5.2 with a bunch of thousands of miles on it and I very much love it. I also have concerns about the decoupler, but there's a caveat: I bought mine as a private transaction from someone who put ~250 miles on it and wasn't in to it. My gain. But here's the thing, before I made this purchase I visited three Trek dealers in my immediate area (Upstate NY) and contacted a fourth through their web page. I was ready to buy and very interested in this bike. And in all but the fourth I was ignored to insulted. The fourth was interested in a deal but they're a 3 hour drive away which kinda made that a problem. I've documented my encounters elsewhere on the web and named names so I won't go into the gory details, but in a previous life I wrenched in shops, some pretty high profile, to support my racing, touring and commuting, years ago. I know how not to be a dick. (One time I was stumped by a shifting issue and made an appointment with a Trek dealer in Saratoga, NY and on my arrival was treated to 20 minutes with a tech who clearly was not interested in helping, or being nice at all, and clearly didn't know how to adjust a B screw and seemed fixated on castigating me for using Jagwire cables.) So I'm reviving this post because it's a pretty specific technical question and I didn't want to have some great info duplicated, and I see there are some Trek people reading. I'm able to replace this assembly myself but don't know how to get the parts. Is it possible? At one point I needed to replace the cable guide that exits the head tube and that turned into an US$17.00 ordeal, with the aforementioned shop. No interest in stepping foot in there again. Thanks in advance.

- ?

- 206.7K members

Top Contributors this Month

trek isospeed creaking

- Bikes / Frames

- Sealants & Flat Protection

- Tubeless Tape & Kits

- Tubeless Valve Stems

- Misc. Valve Parts

- Suspension Forks

- Rigid Forks

- Fork Parts / Service

- Rear Shock Parts / Service

- Groupsets / Drivetrain Bundles

- Cranks / Cranksets

- Crank Parts

- Bottom Brackets

- Rear Derailleurs

- Derailleur Hangers / Parts

- Chainguides

- Chainring Bolts

- Chain Tensioners

- Single Speed Cogs / Kits

- Front Derailleurs

- MTB Right Hand Shifters

- MTB Shifter Sets

- MTB Left Hand Shifters

- Drop-bar Right Hand Shifters

- Drop-bar Left Hand Shifters

- Drop-bar Shifter Sets

- Drop-bar Hydraulic Brake / Shift Levers

- Shifter Parts

- MTB Handlebars

- Drop Bars (Gravel, CX, Road)

- Handlebar Tape

- Disc Brakes

- Disc Brake Rotors

- Disc Brake Adaptors

- Disc Brake Parts

- Road Caliper Brakes

- Cable Pull Brake Levers

- Dropper Posts

- Dropper Post Remotes / Levers

- Rigid Seatposts

- Seatpost Parts / Shims / Misc.

- Seatpost Clamps

- Suspension Seatposts

- Saddles / Seats

- Flat Pedals

- Clipless Pedals

- Pedal Small Parts

- Front Wheels

- Rear Wheels

- Rim Tape & Kits

- Complete Headsets

- Headset Spacers

- Headset Parts

- Shifter Cable & Housing

- Brake Cable & Housing

- Misc. Cable Parts

- Multi-Tools

- Chain & Other Lube

- Fork Oils & Lubes

- Grease & Assembly Compound

- Repair Stands

- General Bike Tools

- Hex / Allen Wrenches

- Component Specific Tools

- Tire & Tube Repair

- Frame Tools

- Wheel Tools

- Cleaning Tools

- Degreaser / Cleaners

- Shop Supplies

- Hitch Racks

- Tailgate Pad / Bed Mounts

- Trunk Racks

- Spare Tire Racks

- Rack Accessories & Small Parts

- Frame Straps

- Floor Pumps & Parts

- CO2 Inflation Devices & Cartridges

- Shock Pumps & Tuning Tools

- Frame / Mini Pumps

- Chainstay / Frame Protectors / Fenders

- Bike GPS / Computers

- Computer Mounts / Accessories / Parts

- Camera Mounts / Accessories

- Hydration Packs / Hip Pack / Backpacks

- Top Tube / Stem Bags

- Frame Packs

- Phone / Electronic Bags & Cases

- Night Riding Lights

- Safety / Tail Lights

- Light Parts / Mounts

- Water Bottles

- Water Bottle Cages

- Gift Ideas / Novelties

- Rear Wheel Trainers

- Roller Trainers

- Trainer Accessories / Parts

- Bike Travel / Shipping Cases

- Bars and Snacks

- Drink Mixes

- Supplements / Minerals

- Cable Locks

- Chain Locks

- Folding Locks

- Storage Racks / Stands

- Knee Pads / Shin / Leg Protection

- Elbow Pads / Arm Protection

- Torso Protection

- Padded / Protective Short Liners / Chamois

- Sunglasses / Accessories

- Chamois / Short Liners / Base Layer

- Chamois Creams / Embrocations / Butt'r

- Jackets / Vests / Hoodies / Flannels

- Tees / Shirts

- Hoodies / Flannels / Jackets

- Top Secret Sales (Do Not Tell!)

- Help / FAQ's

- Contact Us / Locations

- Call Us | 1-805-375-4525

- Why Shop With Us?

Currency: USD BRL CAD EUR AUD GBP RUB CLP NZD

- Continue Shopping

- Your Cart is Empty

FREE U.S. SHIPPING ON EVERYTHING!

- USD BRL CAD EUR AUD GBP RUB CLP NZD

The Basics of Upgrading the Fork on Your Mountain Bike (Check Before You Buy!) [Video]

Words by: Liam Woods

When choosing a new fork, it can be complicated figuring out what fork fits your bike. In this blog, we’ll go over the key things to keep in mind when making mountain bike upgrades with a new fork. There are tons of options (including fitment options) to consider so that you can be sure the fork fits your bike. As you read further, we’ll go over the more common questions and discuss the more modern products (roughly ‘09 and newer). There are millions of bicycles out there in the world -- and all sorts of exceptions to “common” -- so please keep that in mind.

Fork Type and Travel

There are lots of bike front forks out there -- literally hundreds. You’ll not only want to get one that fits your bike but is also intended for your style of bike. This can almost always be determined by the travel of the fork. If you’ve got 80-100mm travel, odds are you’ve got an XC bike or general light trail bike; 120mm-140mm, you’ve got a modern-day trail bike; 150-170mm, it’s probably a modern-day enduro bike; and 200mm, you’ve most likely got a downhill bike.

You always want to keep the same fork travel that your bike is made for. When frames are engineered they are designed specifically around a certain travel fork. If your bike is meant for a 100mm travel fork, stick with 100mm and you’ll be happy.

If you desperately want to get a new fork with more or less travel, we NEVER suggest you go more than 20mm away from what the bike was designed around. If you do that, you are taking a major risk of disrupting the structural integrity of the frame and fork. You will also totally mess up the handling characteristics of your bike.

Steerer Tube Size

-Most common steerer tubes these days are tapered, which is 1.5’’ at the bottom and tapers to a 1-⅛’’ at the top. This is most common on newer bikes (2009+), but it is very rare or non-existent on older bikes. Older bikes often have a straight steerer , which is just straight 1-⅛’’ all the way. Certain older bikes might have a threaded straight steerer, but that is extremely rare.

- You need to be sure you get the right size steerer tube because certain frames only fit certain steerer tubes. If you are planning to keep your existing headset, those are only designed for a certain size as well.

-Keep in mind there are some other weird steerer tubes out there . Cannondale and Giant are two bike brands that have made some super confusing and proprietary steerer tubes for their bikes only. If you’ve got one of those… you may be in for a struggle.

-This seems obvious but as there are three wheel sizes these days (26’’, 27.5’’ and 29’’), it makes a big difference. So know your wheel size because bike front forks are specific to wheel size.

-To add a bit more complexity, you’ve got Fat bikes and Plus bikes that use one of the three common wheel sizes , but need a different fork because of the super wide tires. If you’re in this boat, you’ve got to figure out what you’ve got and get a fork with the same spec. Eg. 27.5+, 29+, Fat Bike specific, etc.

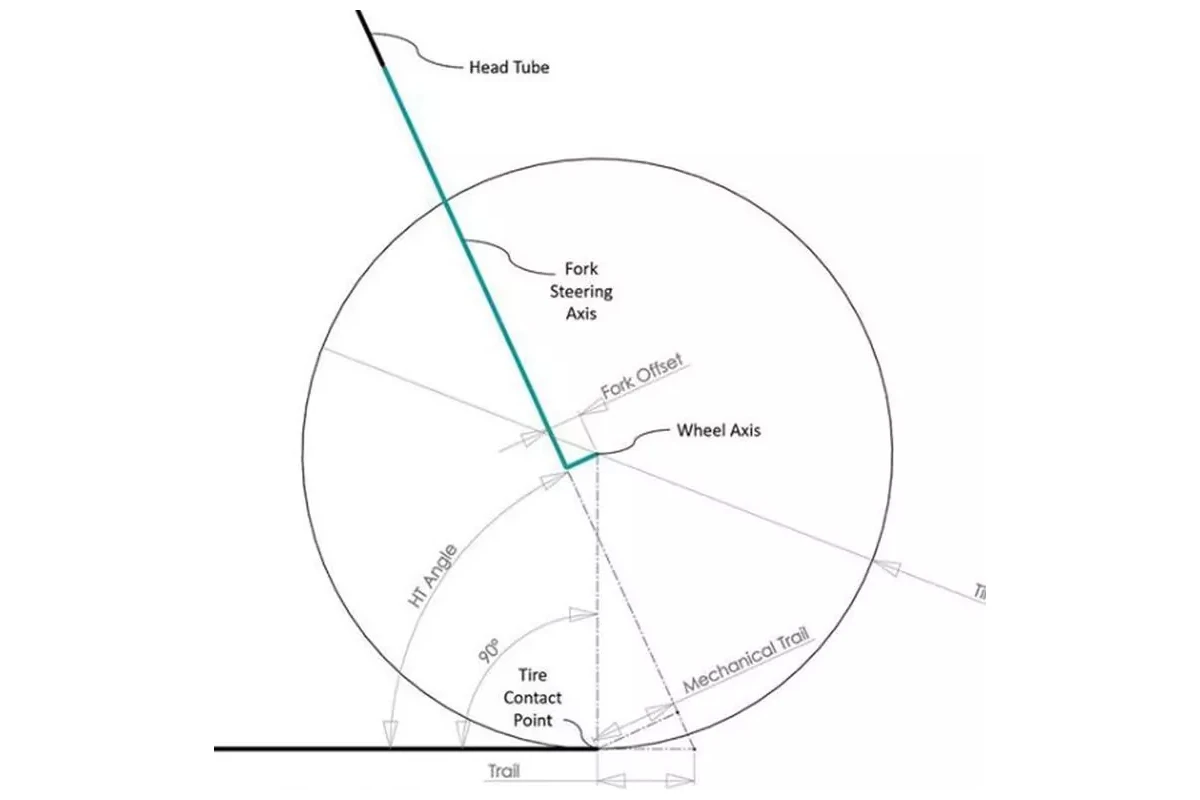

-This is only important for 29’’ wheeled bikes. Offset is how far the front hub sits out in front of the imaginary line that runs through the steering axis. All forks just come in the offset they come in, however, many forks made specifically for a 29’’ wheel are offered in two offset types. Standard and 51mm offset. The majority of modern-day 29’r frames are engineered around a 51mm offset fork as the 51mm offset simply works better with the 29’’ wheel. In some cases, there is a 29’r frame that is designed around a traditional offset, but that is rare and becoming more and more uncommon.

-If you have a 26’’ wheel or a 27.5’’ wheel, don’t worry about this at all. If you have a 29’r then you need to make sure what fork offset your frame is intended to use, very likely and most common it will be designed for a 51mm offset. I'm not going to explain what fork offset does as that is a whole topic on its own, one which we explained in our video on Fork Offset Explained .

-If you want to geek out more on fork offset, PinkBike wrote a great article you can read here .

-You’ll want to get a fork with an axle that fits your front hub. Although 15x100 axles are very common , there are plenty of other “common” ones these days like the 15x110mm Boost axle, or the 20mm axle which is and always has been only 110mm wide, or the quick release axle also called QR or 9mm. Keep in mind a 15mm axle can also be called QR15, this means the 15mm axle has a quick release lever as shown in the pic below. Some 15mm and some 20mm axles have a QR feature and are often called QR15 or QR20 but that simply refers to the way you install/remove the axle from the fork. When you just hear "QR axle" with no reference to 15 or 20 then that means 9mm quick release style and not a thru axle. The 9mm QR axle is not a thru axle so the fork does not come with an axle and looks like the RockShox fork image shown below. 9mm QR is more old school and/or cheaper style. And of course, don’t forget the ever confusing Fat Bike axles... but that is a whole other topic.

-Another confusing thing: The Predictive Steering hub. So far this is only available for RockShox RS1 forks, and if you have an RS1 fork you can only use the Predictive Steering hub. At the moment no other forks but the RS1 use this style axle/hub.

-Know your hub, know your axle and get a fork that matches. Or you can opt to buy a new front wheel/hub/axle conversion kit if that option is available.

Brake Mount

-There are two mounting types (on modern-day MTB’s made for disc brakes), post mount and I.S. mount. Post mount is where you only have two bolts that mount the brake caliper to the fork , and they thread directly into the fork. The I.S. style mount always needs an adapter, two bolts go through two holes on the fork and thread into an adapter, then two bolts come straight down from the brake and thread into that adapter. Post mount style is more common on 2010+ bikes , and I.S. is more common on older bikes. But there are always exceptions.

-The 160 post mount is the most common on 2009+ bikes/forks. This means you can mount disc brakes directly to the fork, no adapter is needed and it will be spaced for a 160mm rotor. However, some forks like the Fox 36 series use a 180mm post mount . Newer Fox 40’s use a 200mm post mount, where the old ones used a super confusing I.S. mount that worked with a 160mm I.S. adapter but was spaced for a 203mm rotor.

-If you’ve got an older bike or entry level mountain bike you might have V-brakes. These mounts work and look entirely different than disc brakes. There is only one type of V-brake mount for mountain bike forks. So if you’ve got V-brakes and intend to keep them, you will need a fork with V-brake mounts.

-Brake adapters deserve an entire blog post of their own. (Or a dictionary-sized book!) The topic is seeming to get less complicated as time goes on but is still one of those things where lots of forks used different sizes and styles of mounts over the years.

Air vs. Coil??:

Air VS Coil, the debate that still goes on everyday. When you are looking to upgrade your suspension fork, it's likely you will be looking at an Air fork. They are more adjustable, feel smoother most of the time, and normally they are the upgrade option. If you currently have a lower end coil fork, an air fork will make a huge improvement. Now, there are a few coil forks coming back to life in the mid-high end range, like MRP Ribbon Coil, CaneCreek Helm Coil, and the new Marzocchi Z1 Coil fork, are new coil options if you want a set it and forget it fork. If you are also looking to maybe turn your mid-high end fork into a coil fork, you can look at Push Industries ACS-3 coil insert kit.

How Much Should You Spend?:

The last thing to consider is how much do you want to spend? This is hard to answer as it depends on your budget, riding amount, style, as well as what bike you are putting it on.

If you are upgrading a bike that is more than 10 years old, it's likely that you might want to think about even making those upgrades. For a little bit more money, you can often get a more modern mountain bike that has newer standards and geometry.

If you have a bike that is only a few years old, it's very likely you can make some upgrades that will work for your bike and might be future proof as well if you wanted to upgrade other parts as well. It also depends what you are looking for in your fork upgrade. Do you want a better feel, more travel, more adjustments, or lighter weight? Those are all things you should consider when looking at new forks.

Generally, the more money you spend you get better performance, in trail and XC forks you get a lighter weight fork and a better feel, on trail/enduro forks you normally get better performance, stiffer chassis, and more adjustments.

So are you the type of rider that needs any of those things? Then you might want to look at the upper midrange to high end forks. If you just want something that feels a bit better than you can probably look around the entry level - mid range type of forks.

Beyond all these little things, you’ve got loads of options as far as features you want on your fork: lockout, compression, rebound, air or coil spring, etc. These require their own blog posts as well . All in all, this stuff can be more than a bit confusing…

Final Thoughts:

Wow, that is a lot of information to digest and think about. Upgrading your fork can get you some major performance improvement but it’s important to understand the right model for your bike. Also consider things like your bike's age, and how much it's worth to you. Then look at Wheel Size, Axle Type, Steerer Tube Type, Travel amount, Brake Mount type, and fork offset. With so much to consider, it's a great option to contact our customer service team, the experts at Worldwide Cyclery are here to help you get the correct fork on your bike, maybe give you some options to choose from and get you the best fork for your bike.

This article was written / authored by Liam Woods. Liam has been in the bicycle industry for over 10 years as a racer, professional mechanic, service manager and as of late, media and content creator. Liam has ridden thousands of different bikes , ridden countless components , tested endless MTB apparel of all kinds and written reviews on it all. He's a key piece to the Worldwide Cyclery "All Things MTB" content creation puzzle. He also makes consistent appearances on the Worldwide Cyclery YouTube channel and Instagram .

November 15, 2020

Bike Knowledge › Fork › Fox › How To › RockShox › Suspension › Video ›

Top Products For You...

Recent blogs.

- Fox Live Valve Neo - Is this the Most Advanced Shock?

- Building the Perfect Yeti ASR: Jeff’s Custom MTB [Video]

- An Epic Mexican MTB Adventure, Fox NEO, Plus Listener Questions You Can't Miss! Ep. 142 [Podcast]

- Top Mountain Bike Products Under $50! [Video]

- Fox Transfer Neo - Is this the AXS Reverb Killer?

--- Shop Info ---

- Videos / Blog Articles

- Contact / Locations

- Demo Bike Program

- Custom Bike Builds

- Miles For NICA

- We're Hiring!

- Affiliate Program

- Accessibility Statement

- Refund Policy

- Terms of Service

- Privacy Policy

--- Stay In Touch ---

Newsletter signup -.

By subscribing to Worldwide Cyclery text messaging, you agree to receive recurring automated marketing text msgs (e.g. cart reminders) to the mobile number used at opt-in on 31691. Consent is not a condition of purchase. Msg frequency may vary. Msg & data rates may apply. Reply HELP for help and STOP to cancel. See Terms and Conditions & Privacy Policy .

© 2024 Worldwide Cyclery

The path to smoother roads Since the inception of the first bicycles, there have been three fundamental truths: We love to ride fast. We love to ride far. We love to feel good while we do it. Creating a bike that’s great at all three isn’t easy. Stiff bikes handle like a dream under speed and force but can leave your body fatigued and your hands numb. Bikes that elevate comfort feel great on long rides but can waiver under pressure at high speeds and compromise pedalling efficiency. Achieving both comfort and performance in one bicycle? Now that was a real mission. Fortunately for all of us, the engineers at Trek are never ones to turn down a challenge. Our team spent countless hours exploring suspension systems, elastomers, vibration dampers and more, before finally landing on our golden ticket in 2012 – the IsoSpeed. Time has raced by since the IsoSpeed first hit the road, but we’ve been quietly perfecting it ever since.

How it works IsoSpeed works by absorbing bumps in the road and trail, so you can ride stronger and more comfortably without sacrificing the feel and efficiency of a traditional bike. It challenges other vibration-damping tech by maintaining the same diamond-shape frame as traditional bikes but decoupling the seat tube from the frame. This allows the bike to respond and manoeuvre just like a standard race bike, while the decoupled seat tube enables enough vertical flex to elevate comfort for every rider. This simplified and smart design soaks up vibration for a smooth ride without bogging you down with energy-gobbling suspension.

The proof is on the podium Since its creation in 2012, the IsoSpeed has held its own under Trek’s top athletes through the most notoriously challenging races in the world. From Strade Bianche and Ronde van Vlaanderen to Paris Roubaix, IsoSpeed has helped our athletes conquer body-numbing cobbles and rough roads, giving them the energetic edge to hammer for the breakaway and take their place on the podium.

Creating the tech to smooth your ride IsoSpeed was first created to provide faster bikes for our professional racers competing on rough roads and rugged cross-country mountain bike trails. Our team riders are a key element in our development process. They spend more time on the bike than just about anyone, and scrutinise the most minute details, providing us with invaluable feedback that’s paramount to building the best bikes in the world. But we don’t just leave the judgement up to human perception – we also test and validate IsoSpeed technology in our lab. We built a proprietary treadmill that mimics real-life conditions and use sensors to monitor vibrations and forces transferring from the road to the rider, collecting data to determine how we can dissipate vibrations through the bike. On paper it may just look like a lot of numbers, but these numbers help us provide a meaningful difference in the quality and comfort of every ride.

Find your IsoSpeed Whether you spin on open roads and roads less travelled, or say goodbye to the road altogether, you can find a bike that brings IsoSpeed’s ride-smoothing technology to your next adventure.

The Domane delivers incredible endurance comfort without sacrificing speed thanks to IsoSpeed technology. From tarmac roads and hard-packed gravel to the cobbles of Roubaix, the Domane is smooth, fast and fun.

- See the bikes

The Checkpoint is an adventure-minded gravel ride built for taking on the most gruelling races and exploring long-forgotten dirt roads alike. It pairs a versatile design with IsoSpeed for elevated comfort on the long haul.

The Procaliber is a game-changing XC mountain bike machine that pairs classic hardtail efficiency with the fatigue-fighting comfort of IsoSpeed for a ride that feels like first place.

- Search forums

- General Ebike Forums

- Discussion by Brand & User Reviews

Known Issues & Problems with NCM Products + Help, Solutions & Fixes

- Thread starter troehrkasse

- Start date Mar 21, 2020

troehrkasse

Ebr webmaster.

- Mar 21, 2020

No Ebike is perfect, this is a thread dedicated to sharing known issues or problems with electric bikes from NCM as well as any help and solutions you know of. Sometimes that means a DIY fix and other times it can mean a recall, software update or part replacement by a dealer. Please be respectful and constructive with feedback, this is not a space for hate speech. In many cases, representatives from the company will see feedback and use it to improve their product. In the end, the goal is to enjoy riding and help each other go further and be safer.

FullyCharged

Active member.

- Mar 27, 2020

john peck said: *I've fashioned an adapter that allows me to use the 2 shorter Juiced 21Ah & 8Ah batts. Click to expand...

Well-Known Member

FullyCharged said: Can you make a thread on this please. Would like to see what you did. Click to expand...

john peck said: THat was pretty simple. Sprayed wd40 on bottom receiver & the bottom of the battery. Mixed a gob of Instamold* moldable, non-toxic plastic, mashed into the receiver, pushed the battery down into it 'til it snapped into the connecter, & clamped it into place with a hose clamp 'til the plastic set, (after trimming the excess). You could just use a hose clamp with a folded piece of 60 grit sandpaper to hold it in place. The mounting system is the same as Juiced, but for a longer battery. *see ebay Click to expand...

FullyCharged said: Got a pic of this setup? You have peaked my interest. Can you remove the Instamold easy to switch back to the stock batteries? Click to expand...

- May 4, 2020

Having tried changing the wheel size and deciding it made no difference, today I noticed that the speed reading is WAY off! Mine is 7-8kmh fast- vs iPhone GPS - so the pedal assist switches off well before it should. I changed the wheel size to 20 and it’s still off but by my admittedly poor maths I should now at least continue to get assistance closer to 25kmh and maybe a little bit beyond?!

Sounds aggravating, I'm glad mine arrived preset for 29ers & mph

- May 11, 2020

- After owning for 3 weeks power cut off mid ride due to loose contact on one of the cables that connects to display. I had to take it back to bike store & after diagnosis they had to resolder.

- Water leaked into PCB board located on battery on/off button due to riding in rain. Had to get replacement PCB board installed. Mechanic covered top of battery with electrical tape to prevent happening in the future. He said this is a common issue.

- Rear derailleur cable broke & had to be replaced.

- Rear wheel spokes have broken 3 times. I’ve now organised for a new rear wheel which will hopefully fix issue. Mechanic at shop said that broken spokes is a common issue with rear wheel hub drive bikes due to weight.

U, I'm at 1400 mi. Taping over the switch was something I did as prevention on my CCS, so perhaps I should on the NCM. I popped one spoke on a pothole, my fault, tire not properly inflated. With the warmer weather & use, my cables stretched a bit I had to tune 'em some. The spoke thing is an issue, I think any motor 500 watts or more should have #11 spokes, THe replacement wheel I bought for the CCS has them. That wheel is fine, but the CCS is now a parts bike, I have the 29er Moscow which is holding up well. largely because of lessons learned on the CCS. I think a 29er is less prone to the spoke issues because it spans over bumps & ruts better. I do think the discs are too thin, more so than the CCS. There's an ever-so-slight warp in front I can feel at very low speed but not noticeable otherwise. The biggest plus for this bike is how well it climbs. Not as fast as the CCS was, but there's a lot of steep going here & the moscow climbs so well. There is good advice on shifting in the manual that might have prevented U's broken derailleur cable. Take off in too high a gear is ill advised as is with too low because this motor is very goosy with instant torque, For that reason. when starting off, I tap the throttle a tad before stomping the pedal. When shifting you have to ease off pedal pressure for a blink. If you are bearing down hard if may be too much for the cable. My advice would be to read the manual carefully & follow it to the letter. P.S. ya gotta keep an eye on tire pressure; too little & the rim will bottom out on bumps or holes & pop spokes. This is important if you're a big rider like me.You might even want to go to a bigger tire, 2.5" to 2.8" in the rear.

- May 18, 2020

john peck said: Thousand mile evaluation of the NCM Moscow: No problem with the bike, but I did have a flat when a wire broke loose from the tire bead & punctured the tube. The more i understand the German engineering, the better the performance becomes. I'm a big guy & have put back some of the 100 pds I lost as muscle. This bike inspires one to put more self into pedaling. Having a triple chainring is a real plus. There are lots of ups & downs here, but this bike will climb a tree. One local hill ascends 115 ft up from the beach in a little more than a 1/4 mile, & the bike climbs it with ease on the middle chainring. The owners manual is very useful for getting the most out of this modestly priced, rugged bike. It's still quite rideable without power on the small chainring, & I often take shorter rides without installing the battery. It's basically a hardtail Mtn. bike with power & 4 3/8" fork travel compared to 3" travel on my CCS, It's not as fast as my CCS 'was'. Changing a tire was so much easier, The symmetrical stays will handle a 3" tire, but the 2.25"s are just fine on the beach except for loose dry sand.. It comes fairly bare bones, but cheaply enough with wiggle room to personalize. I got mine at $1300 the day after order from Leoncycle-us in Seattle, but their latest email yesterday has it at $1059 That is a really good bargain if you are not put off by the name, Moscow. I think that was meant to sell this German bike in Russia. The fat tire version is called Aspen,( trite). I'd have called it Cheyenne. All NCMs are named for cities. I've seen a bunch sold to other outfits with different paint & single chainrings going for $1500. It's a bit noisy on take off, very torquey & a tad goosy. The motor has tempered metal gears, not plastic.. For $200 more you can get a Moscow+ with a 16Ah battery, 8 spd. & 2 motor cutoff levers, but I'm getting better mileage with the single cutoff, 7 spd, 13Ah than I did with my 21Ah CCS.* If you ease off pedal pressure upon shifting, it's very smooth with the 7 spd. Gearing is just fine with the old standard mtn. 48 38 28/ 14-28. There's really no reason to mess with it, & it would void warranty any way. The Schwalbe Smart Sams are surprisingly fast rolling, comfortable, & handle well on all surfaces, but after the flat I put a more rugged Bontrager on the back. There's a simple trick to dropping the rear wheel. After loosening the nuts just use a cone wrench to align the flat surfaces of the axle with the sides of the dropout. When tightened, the axle locks into the dropout. There's no need to remove a retainer clip & the derailleur as with my CCS . After adding a 5" riser bars, I had to move the thumb throttle to the left, Mounting points are a bit strange. but I managed to reconfigure a rear rack with a space for a 2nd battery yet would still take panniers & tie- down space on top. It was something of a challenge creating a mount for my single wheel Aesom trailer which converts to a plow, harrow or rake, My personal conclusion is the this is the best, most versatile bike you can buy for the price, including many costing twice as much or more. *I've fashioned an adapter that allows me to use the 2 shorter Juiced 21Ah & 8Ah batts. PS.Mine's a 29er, also comes 27.5" Click to expand...

stevieray611

- May 19, 2020

I've used my Moscow 5 days a week for a year daily 24 mile round trip . The problems I've had so far are mostly ware and tear . New tyres , 6 new rear wheel spokes, new gear mech hanger after spoke took it out , new chain , new saddle . The roads in uk are in a pretty poor state so I'm not blaming the build at all . I'm pretty happy with the moscow . Only this wk the battery has decided not to take a charge .due to the times NCM aren't easy to contact so I'm gonna try a new charger first see if it's a charger or battery issue . I'll update when I find out

- May 20, 2020

Update it's def the battery so now the dilemma , brand new battery or get the old one re celled to a higher speck either way it's gonna cost lol .

- May 21, 2020

Just an FYI: If you take off the rear wheel for any reason,(tube,tire,spoke) Do not squeeze the rear brake lever without the wheel in place. The brake self adjusts; you will either be unable to replace wheel or have signifigant brake drag. Read the manual on brake adjustment. If this has happened there's a simple fix. Loosen the upper & lower alignment bolts, (do not remove, these are not the bolts that mount to frame ) Rotate the wheel & check pad clearance, ( should return to normal when self-adjust releases) Outside pad should be a bit closer to the disc but not touching. With wheel rotating freely, tighten bolts & adjust the barrel adjust on the lever. The manual & illustration is more helpful if you've got one. P.S. I can't believe my rear derailleur is still in perfect tune after 1500 miles without being touched

stevieray611 said: Update it's def the battery so now the dilemma , brand new battery or get the old one re celled to a higher speck either way it's gonna cost lol . Click to expand...

- May 24, 2020

john peck said: Just another tip; IF you have a flat in the middle of nowhere it's a long walk home if you not prepared to deal with it. I removed the stock kickstand & replaced it with a dbl leg '&' a rear mount single stand. The dbl comes with an upper clamp you won't need. Just run the the bolt thru the frame into the lower portion of the dbl. It will lock securely into the frame. (much simpler with wheel off) Why am I doing this? To make tire repair in the field less of a nightmare! The dbl stand let's you drop out & replace the wheel without turning the bike upside down & crushing your display, mirror, or whatever while making the process ' somewhat' easier.... but there's a trick to it! A) Manually slack chain off the chainring. B) After disconnecting the power cable, ( at this point I tape a sharpie cap over the end to protect the connector prongs), C) Remove all washers & nuts from the axle,(you can leave the right side hanging on the power cable) If you simply loosen them, the nut will snag on the derailleur when you drop out the wheel. When tightened the axle twists & locks into the drop out. To drop the wheel, carefully use a crescent on the flat sides to align the axle to drop out, avoiding damage to the threads. (!) D) Slip chain off freewheel & slide out wheel. Replacement: A) lift the stays, ( the frame will now rock forward on the dbl leg.) roll in wheel, loop chain onto freewheel, & lower dropouts onto the axle being careful to align the flat sides of the axle with the dropout slots,( this is just easier without nuts & washers) B) The washers with the tab insert with the tab "under the axle from the outside" first!, then lock washer, nut. Reconnect power cable being 'very' care to align the arrows!! IF this sounds complicated, try doing it with the bike upside down in the field. There's just no simple way to deal with a rear motor wheel, & it's easy to screw up if you don't get it 'exactly' right! This is the main plus for a mid-drive. The plus for a rear motor is that it will get you home on throttle if you are injured or have broken a pedal or chain. Being able to rock the bike on a dbl leg kickstand also makes doing the front easier too, as well as tuning, since your can turn the pedals without hitting the kickstand with the wheel off the ground. (Things not mentioned in the manual ) Click to expand...

jkvt said: Any thoughts on a bottle of slime for use in the field? I've never used it but was thinking of getting some to keep on me for any flats in the field. Click to expand...

- May 25, 2020

I use slime and a liner as I was constantly getting punctures, now touch wood maybe once in a blue moon , tyres wear out before I get a flat these days

Thanks for the info. I'll grab a bottle and hang on to it in case I need it in the field. I think the odds of a flat are pretty slim as I'm using the bike as a commuter and to run errands. It will be almost totally used on the road, then again we have our share of potholes here in Vermont, and I sure have hit some, so maybe that's not as big of a plus as I think it is. Stevieray611, what do you mean by you use it as a liner? Do you pump it as preventive or have a tube that comes with it?

Similar threads

- May 3, 2023

- Maxfoot Forum

- Apr 18, 2023

- Alizeti Forum

- Tempo Forum

- Wildsyde Forum

- We use cookies to ensure that we give you the best experience on our website. Accept Learn More…

- Trek Manuals

- Domanee 2017

- Service manual

Trek Domanee 2017 Service Manual

- page of 26 Go / 26

Table of Contents

- 1 Isospeed Seat Decoupler and Seat Mast

- How It Works

- Installing the Seat Mast

- Installing the Adjustable Seatmast Slider and Securing the Seat Mast

- Adjusting the Ride

2 Front Isospeed

- Installing the Front Isospeed System

3 Installing the Fork

4 installing the di2, 5 installing the shift cables.

- Securing the Rear Derailleur

- Securing the Front Derailleur

6 Installing Fenders

- Securing the Rear Fender

- Securing the Front Fender

7 Installing Chain Keeper

- Securing the Chain Keeper

Advertisement

Quick Links

- 2 Installing the Adjustable Seatmast Slider and Securing the Seat Mast

- 3 Front Isospeed

- 4 Installing the Front Isospeed System

- 5 Installing the Fork

- 6 Installing the Di2

- 7 Installing the Shift Cables

- Download this manual

Related Manuals for Trek Domanee 2017

Summary of Contents for Trek Domanee 2017

- Page 1 2 0 1 7 D O M A N E E S E R V I C E M A N U A L...

- Page 3 2016 DOMANE Rear IsoSpeed cover drive side Pivot bolt Bearing 19mm x 10mm x 5mm Pivot locating washer Rear IsoSpeed cover non drive side m5 x .08 x 24mm Flat washer m5 x 10 x 1.0mm Button head screw m5 x 10 Curved washer m5 x 18od x 1.5thck x r11 Spring lock washer...

- Page 4 Front Isospeed lower cover Elliptical nut, m8 x1.0 x 6mm Front Isospeed decoupler Washer, 16od x 10.10id x 1.125 length Screw, m8 x 1.0 x 14mm, 4mm hex Pre-load spacer Headset bearing Headset compression ring Front Isospeed headtube cover Headset top cap...

- Page 5 Congratulations and mountain bikes in Trek’s lineup. If you’re reading this assembly manual, But Trek never stops developing. With the odds are you’re about to lay hands on the all-new Domane SLR, we set out to devise a smoothest, most efficient race bike Trek has solution that would both expand the range ever created.

Page 6: Table Of Contents

Page 7: isospeed seat decoupler and seat mast, page 8: installing the seat mast.

- Page 9 INSTALLING THE ISOSPEED SEAT DECOUPLER AND SEAT MAST On the non-drive side, insert the other pivot bolt Repeat the tightening process with the torque assembly from step 3 through the bore hole and wrench on the non-drive side. thread into the axle. Insert 5mm hex wrenches into both pivot bolts and slowly turn each clockwise.

Page 10: Installing The Adjustable Seatmast Slider And Securing The Seat Mast

Page 11: adjusting the ride, page 12: front isospeed.

- Page 13 INSTALLING THE HEAD TUBE ISOZONE While pinching the front IsoSpeed decoupler Place a finger inside the decoupler and push the between two fingers to hold the washers, carefully screw towards the outside of the head tube. guide it into the cavity in the head tube. Stop when the holes in the decoupler are aligned with the holes in the frame.

- Page 14 INSTALLING THE HEAD TUBE ISOZONE Place one hand on the opposite side of the head To fully tighten, apply good pressure while tube (9a) and with the other, insert the torque key turning the torque key in the nut. This will into the nut and apply pressure with both hands prevent the bolt inside the decoupler from until the nut seats into head tube (9b).Then turn...

Page 15: Installing The Fork

Page 16: installing the di2, page 17: installing the shift cables.

- Page 18 INSTALLING THE SHIFT CABLES To create the correct amount of slack in the cable, Cut the cable at this mark. Clean the cable end and do not make it too loose (A) or too tight (B). install a cable stop. TIGHT LOOSE Thread shift cable through the housing and...

Page 19: Securing The Rear Derailleur

Page 20: securing the front derailleur, page 21: installing fenders, page 22: securing the front fender.

- Page 23 INSTALLING FENDERS Install the top of the fender to the backside of the Reinstall the front wheel. Adjust the fender at the fork crown. Place the fender at its highest possible fork crown so that there is clearance between the setting.

Page 24: Installing Chain Keeper

- Page 26 PN 543481...

Rename the bookmark

Delete bookmark, delete from my manuals, upload manual.

Moskva-Class Cruisers

Separate design teams often attempt to meet a set of ship specifications with completely different, although equally valid, strategies. To fulfill the requirements issued in April 2169 for the successor (NX-223) to the Daedalus class, which was introduced at the end of the Romulan War, Prosser & Ankopitch proposed a ship with an extremely large, spherical command hull attached to a nearly vestigial engineering hull. The proposal from the Mikoyan-Tupolev-Dassault Bureau used a long narrow command hull with a minimal frontal silhouette counterbalanced by an equally long engineering hull.

The engineers at Tezuka-Republic decided that the division of ship's functions between a command/crew hull and an engineering hull was arbitrary and unnecessarily restricted design options. Therefore, rather than gathering all the specified facilities in a single hull, their design TR-223A spread them across two hulls, as in Daedalus , and segregated the SSWR-IV-C warp core to a "bustle" at the extreme aft end of the secondary hull. This bustle could be separated easily and quickly from the rest of the engineering hull in the event of a warp core breach. The now-unpowered warp nacelles would then be shed. In this way, the demands of safety would be met without warp dynamics being degraded either by an excessively large frontal silhouette or by longitudinal warp field imbalance.

Although the Ship Specifications Review Board praised Tezuka-Republic for its creative solution to the problem of admittedly contradictory requirements for extreme safety and improved warp performance, they were forced to disqualify design TR-223A for not precisely meeting contract specifications. Therefore, in October 2171, construction contract NX-223 for Starfleet's new cruiser was awarded to Prosser & Ankopitch for what would become the Wasp class .

However, almost no one was happy with the new Wasp ships. Even before the contract was awarded, voices within Starfleet and within industry had strongly criticized the specifications of April 2169. These critics charged that they would lead to a mediocre, albeit safe, fighting ship. Two separate classes were needed, not a single class that was neither a proper explorer nor a proper warship. When Wasp was finally launched in 2173, her performance during precommisioning trials clearly showed that the critics had been correct. Although the performance problems were related in part to the continuing unavailability of the more powerful Tezuka-Republic Hiryu ("Flying Dragon") mark III warp nacelles, Wasp was obviously not the ship Starfleet had hoped for.

In a second attempt to obtain a reliable and capable warship, new specifications (NX-374) were issued in September 2175, little more than a year after USS Wasp had entered service. Adding to this sense of urgency were intelligence reports suggesting that the Romulans had either developed or otherwise acquired matter/antimatter (M/AM) reactors. This time the specifications put less emphasis upon safety. The original requirement for completely separate command and engineering hulls was eliminated; instead, any hull configuration was allowed as long as the warp core could be quickly separated from the rest of the ship. Furthermore, requirements for speed, acceleration, and maneuverability both under impulse power and under warp power were increased, as were performance levels for target acquisition, tracking, and servicing.

These new specifications were a clear, albeit belated, admission that the critics had been correct all along: one class could not be expected to serve as both an explorer and a main battleship. In fact, starship technology was not considered sufficiently mature for a single ship to adequately fulfill both mission profiles until 2245, when the Constitution -class heavy cruiser was launched. (The controversy continues even today in the wake of the problems of the Galaxy -class explorer.)

Luckily, the designers and engineers at Tezuka-Republic had not been idle since their disappointing loss of the Wasp contract in 2171. Instead, they had spent their time refining design TR-223A so that their new entry (TR-374A) was markedly superior to what had been submitted 5 years earlier. In particular, the new SSWR-V warp reactor allowed the bustle to be made smaller, lighter, and even more easily separable. Therefore, it was hardly surprising when in November 2176 Tezuka-Republic was awarded the production contract over designs from Shimata-Dominquez, Prosser & Ankopitch, Mikoyan-Tupolev Dassault, Monarch R&U, and Thornycroft/Ebisu for what was to become the Moskva class.

However, engineering prowess may not have been the only factor in Tezuka-Republic's winning of the contract. There were accusations that the delay in delivery of the Hiryu warp engines was an attempt by Tezuka-Republic to prevent Wasp from reaching her designed performance levels. While no conclusive incriminating evidence has come to light, the delivery of the long-awaited engines shortly before the scheduled launch of Moskva in December 2177 is certainly suspicious. Tezuka-Republic maintains that if their submission of 2169 had been selected, its performance would also have not have met design specifications without the Hiryu engines. However, critics charge that TR-223A was not as reliant as Wasp on the type of engine used. Furthermore, once the Wasp contract was awarded, and even after Wasp was launched, Tezuka-Republic certainly made no efforts to accelerate delivery of Hiryu.

These controversies were soon rendered moot as the new Moskva class was recognized as a significant advance in starship design. The most important new feature was Moskva's discoid primary hull. Earlier designs had chosen a spherical primary hull for reasons of economy. Simple geometric relationships dictate that a spherical hull has the smallest surface area for a given volume. Therefore, construction costs are lower and shields are more efficient. Furthermore, institutional inertia had led nearly all exploratory cruisers originating until that time from the National Aeronautics and Space Administration, the United States Astronautics Agency, the United Earth Space Probe Agency, and its successor organizations to have spherical hulls.

The designers of USS Moskva employed a biconvex disc for several reasons. Their initial motive was to increase hull volume while minimizing both frontal and lateral silhouettes. A warship with large frontal and lateral silhouettes would be at a greater disadvantage in most tactical situations than would be a ship with an increased superior silhouette. However, the discoid hull allowed the traditional radial layout of command hulls to be retained.

More important than these tactical advantages were functional advantages. As was shown with the Wasp class, warp field geometry would have been awkward if a spherical hull with its relatively large frontal area had been used. The discoid hull was also found to channel warp field flow across its upper surface towards the bussard ram scoops of the warp nacelles. This channeling effect improved field efficiency at all power levels and speeds. As the understanding of warp field mechanics was refined, the trend towards saucer-shaped primary hulls would be intensified in later Starfleet vessels.

In most respects, the Moskva class continued design and engineering trends established in the Comet and Daedalus classes introduced at the end of the Romulan War. As in these classes, ship functions were clearly divided between a command/crew hull and an engineering/propulsion hull. The bridge was returned to its customary position atop the command hull and the shuttlecraft bay was again placed in the secondary hull. The fusion reactor was centered along the longitudinal axis of the ship, and impulse thrust ports exited immediately in front of the warp bustle detachment seam.

Weaponry was the then-standard mix of fusion-warhead missiles and lasers. New to this class was an early type of ultraphased pulse laser cannon, two of which were mounted in the chin of the primary hull. Although the on-target energy output of this new weapon approached that of early phasers, its power requirement was higher and its range was substantially less. However, subsequent refinements lead to steady improvement and, ultimately, to the development of true phasers in 2202. Although Moskva -class ships were the first to be fitted with phasers in 2204, lasers were still carried by the Moskva class and later classes until the 2220s. Finally, warp capability was supplied by the long-awaited Hiryu mark III drive units.

The first ship of the new class, USS Moskva (NCC-374), entered service with Starfleet in April 2179. An additional 30 ships (NCC-375 to NCC-404) joined the fleet through 2183. Moskva -class ships gained immediate popularity with officers and crews. First, total laser firepower was increased some 75% over that in the preceding Wasp class. Second, because the ship's mass was more equally distributed along the longitudinal axis than in the Wasp class, Moskva was significantly more maneuverable at both sublight and warp speeds. Finally, the more warp-dynamic design allowed greater cruising and maximum speeds.

The Moskva class had an outstanding safety record. No ships were lost because of mechanical failures. However, an incident occurred aboard USS Johannesburg in 2186 when a faulty nacelle flow monitor falsely indicated a runaway positive feedback power loop within the plasma flow governor. Believing that a catastrophic warp core explosion was imminent, Chief Engineer Roberta Bocharnikov ordered the warp nacelles and warp bustle to be separated. Although unnecessary, these maneuvers were successful in causing the separated warp core to initiate its automatic shut-down routine. The warp core, nacelles, and the rest of the ship were towed to Starbase 13, where they were successfully re-mated. Despite her supreme embarrassment, Bocharnikov oversaw the reassembly and relaunching of Johannesburg and retained her position as chief engineer.

Although most ships of the Moskva class had left front-line service by 2215, some continued to serve as auxiliaries and training vessels until the 2240s. After retirement from active duty, Moskva -class ships were used as testbeds for many emerging technologies owing to the similarities of their layouts to those of succeeding classes. USS Moskva was the site of the first successful ship-to-surface transport of a Human being in 2206, and USS Gato was the first ship to fire photon torpedoes in 2214. In addition, Taurus -class tugs, which entered service in 2182, and Sanford -class repair tenders, which entered service in 2185, were derived from the Moskva class and used the same primary hull and warp drive assembly.

The Moskva -class cruiser USS Aurora (NCC-377), a participant of the Battle of Eohippus IV, is on display at the Starfleet Museum.

Standard displacement: 67,750 t

Crew complement: 160 (27 officers + 133 crew) Weapons: 8 Type VI laser turrets (8 × 1 mounts), 2 Type VII laser cannons (fixed mounts), 2 missile launchers with 36 Spartak missiles Embarked craft: 4 medium cargo/personnel shuttlecraft, 2 light personnel shuttlecraft, 5 fighter/scouts Warp drive: SSWR-V-A spherical cavity M/AM reactor with 2 Hiryu III nacelles Velocity: wf 4.0, cruise; wf 5.0, supercruise; wf 5.2, maximum Units commissioned: 31

IMAGES

VIDEO

COMMENTS

2 FRONT ISOSPEED TOOLS AND MATERIALS REQUIRED: • 5 mm hex wrench • Torque wrench • Grease A Front IsoSpeed lower cover B Elliptical nut m8 x1.0 x 6mm C Front IsoSpeed decoupler D Washer 16od x 10.10id x 1.125 length E Screw m8 x 1.0 x 14mm, 4mm hex F Pre-load spacer G Headset bearing H Headset compression ring I Front IsoSpeed headtube cover

Trek Front Iso Speed Problems Solved! Sometimes the front iso speed on the 2020-2022 Trek Domane SL and Trek Domane SLR frames can have a creaking noise. I w...

InBlack. 11 posts · Joined 2012. #20 · Aug 4, 2015. Glad I came across this thread in my search for IsoSpeed Decoupler issues. I've been having a pretty consistent "click" coming from the Decoupler for a good time now. It's definitely the decoupler (I've been able to recreate the noise while off of the bike).

The IsoSpeed mechanism is designed to last the lifetime of the bicycle without service. Do not lubricate it. Keep it clean with water and a soft cloth. If the mechanism makes noise or exhibits lateral play, the design allows easy replacement of the mechanism. Take your bicycle to your retailer for service. I then started to research about this ...

View and Download Trek DOMANE SL 2023 service manual online. DOMANE SL 2023 bicycle pdf manual download. ... Page 7 2023 Domane SL/SLR Routing — eTap 6.5Nm 0.7Nm Front derailleur hanger — W531901 Rear brake hose ... Do not perform routine maintenance on the IsoSpeed. Only service IsoSpeed hardware if you are replacing parts or torquing the ...

View and Download Trek Domane SL service manual online. 2023. Domane SL bicycle pdf manual download. ... W329119 Front derailleur cable Housing grommets - W330578 Rear derailleur cable W531901 Front derailleur ... Do not perform routine maintenance on the IsoSpeed. Only service IsoSpeed hardware if you are replacing parts or torquing the ...

Place the washers on the bolt. Tighten the nut to 10Nm while securing the bolt with a wrench as shown below. Page 13 2022 Checkpoint SL/SLR IsoSpeed — SLR 15Nm Seatmast sub-assembly Service the IsoSpeed Seatmast Carefully remove the IsoSpeed covers (2) with a IsoSpeed covers* paint-safe plastic pry bar. Remove the bolt (8), nut (7), and washers.

Service information 16 8. Appendix17 A. Install the front isospeed 17 B. Install the rear IsoSpeed 20 C. Assemble and install the DT storage door 22 D. Install the T47 bottom bracket 24 E. Install fenders 25 26 Install front fender Rear fender chart. 2 3

A quick look at the front Isospeed and how it operates to isolate the vibrations through the front fork.

Resilience on the roughest rides. Performance under pressure shouldn't come at the cost of your comfort. That's why we created IsoSpeed — a fatigue-diminishing comfort technology that lets your bike flex with the road, so that you don't have to. It's engineered to soak up chatter from rough rides while maintaining responsive handling ...

If you're not running a carbon seatpost already, you'll notice a lot more as well. So the answer is yes and no, it's a nice to have. You can set up IsoSpeed to be more or less compliant depending on the terrain you ride. FYI Not all models have adjustable IsoSpeed. The Domane SL5 doesn't but the.SLR model does.

Domane Isospeed Decoupler Fail. I have a question about the Isospeed decoupler on my 2015 Trek Domane 5.2. Recently I noticed that the decoupler was not dampening the ride like it used to. When I took it into the LBS for service they said they could just replace it and it would be fine. Once they got it apart they said that it had corroded most ...

Bicycle Trek 2023 FX+ Service Manual (13 pages) Bicycle Trek SPEED CONCEPT SLR 2022 Service Manual Supplement (22 pages) Bicycle Trek SUPERCALIBER SL Service Manual ... Page 4 Front IsoSpeed lower cover Elliptical nut, m8 x 1.0 mm x 6 mm Front IsoSpeed decoupler Washer, 16 od x 10.10 id x 1.125 length Screw, ...

My Domane SL4 had an annoying creak and it took 1 week and 3 mechanics to figure out a spacer was on backwards in the front isospeed. I like to service my own bikes but I'm hesitant with this one due to the complexities of the isospeed. ... There is a service bulletin available to Trek employees that addresses this issue, as it happens to ...

30-day Unconditional Guarantee. If for any reason you're not 100% happy with your online order from trekbikes.com, you can return it in like-new condition within 30 days. No questions asked. Learn more. Trek Domane IsoSpeed Front Coupler Assembly. Be the first to write a review! $63.99. Model W546556. Retailer prices may vary depending on ...

Madone SLR seatpost / ISOspeed HELP. Hey TR community, I put my Madone on the the trainer for the first time yesterday and I noticed it has quite a bit of sway side to side In the

2020 Domane Service Manual Table of Contents 1. Install common components A. Install and adjust the seatpost B. Install the front derailleur C. Install the rear derailleur D. Install the chain keeper 2. Route and install brakes A. Install rear brake in frame B.

Post mount style is more common on 2010+ bikes, and I.S. is more common on older bikes. But there are always exceptions. -The 160 post mount is the most common on 2009+ bikes/forks. This means you can mount disc brakes directly to the fork, no adapter is needed and it will be spaced for a 160mm rotor.

How it works. IsoSpeed works by absorbing bumps in the road and trail, so you can ride stronger and more comfortably without sacrificing the feel and efficiency of a traditional bike. It challenges other vibration-damping tech by maintaining the same diamond-shape frame as traditional bikes but decoupling the seat tube from the frame.

B) The washers with the tab insert with the tab "under the axle from the outside" first!, then lock washer, nut. Reconnect power cable. being 'very' care to align the arrows!! IF this sounds complicated, try doing it with the bike upside down in the field. There's just no simple way to deal with a rear motor.

Bicycle Trek 2023 FX+ Service Manual (13 pages) Summary of Contents for Trek Domanee 2017. Page 1 2 0 1 7 D O M A N E E S E R V I C E M A N U A L ... Page 4 Front Isospeed lower cover Elliptical nut, m8 x1.0 x 6mm Front Isospeed decoupler Washer, 16od x 10.10id x 1.125 length Screw, ...

The first ship of the new class, USS Moskva (NCC-374), entered service with Starfleet in April 2179. An additional 30 ships (NCC-375 to NCC-404) joined the fleet through 2183. Moskva -class ships gained immediate popularity with officers and crews. First, total laser firepower was increased some 75% over that in the preceding Wasp class.